Carbon nano-sphere/NiCo2O4 composite material as well as preparation method and application thereof

A technology of carbon nanospheres and composite materials, applied in hybrid capacitor electrodes, structural parts, electrical components, etc., can solve the problems of not being able to keep up with functional requirements, limit the total specific capacity, etc., and achieve the effect of excellent charge and discharge performance and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

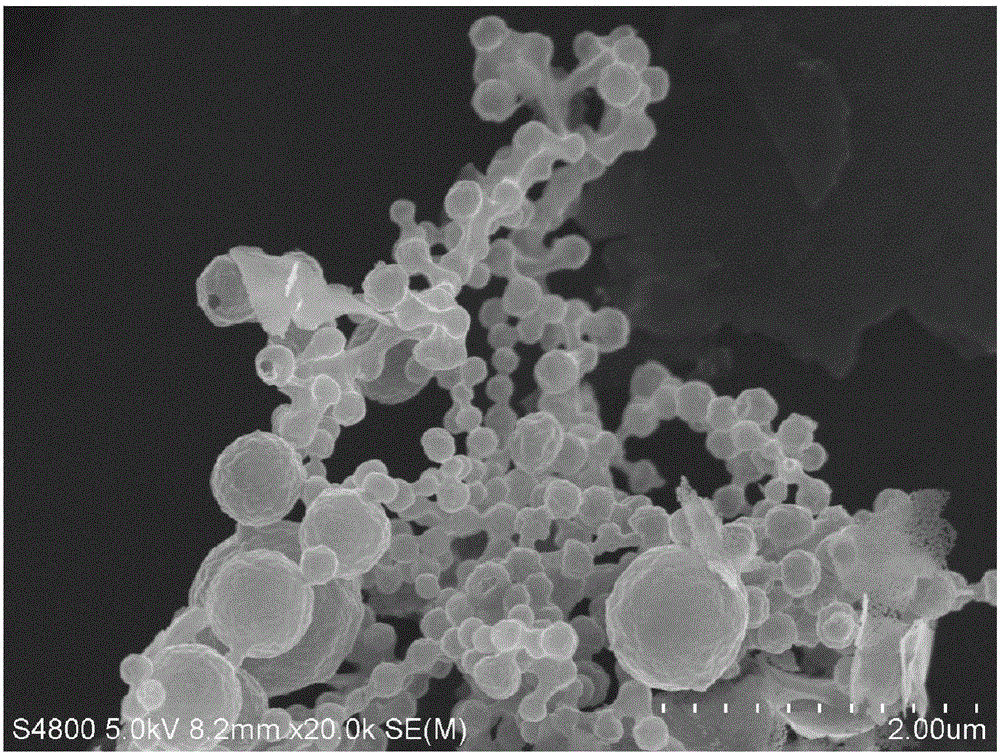

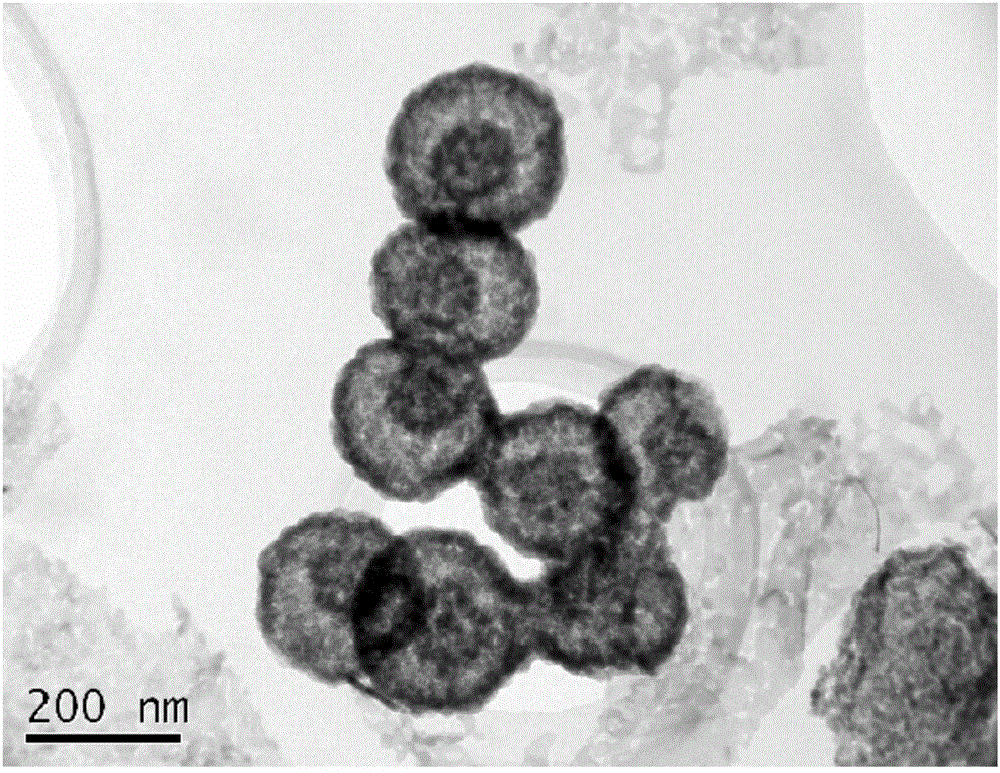

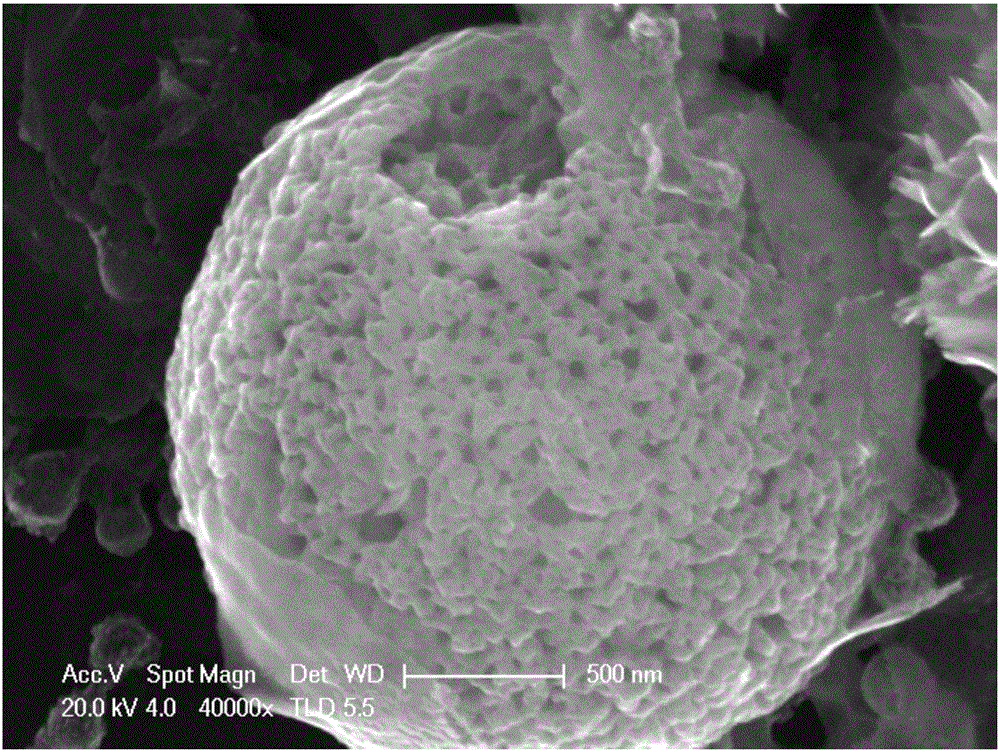

[0028] Take 0.1 g of glucose and add it to 20 mL of distilled water to fully dissolve it, and transfer it to a 25 mL reaction kettle; then heat it to 200° C. and keep it for 24 hours. After being cooled to room temperature, washed with distilled water and ethanol for several times, and dried at 60° C. for 4 hours to obtain carbon nanospheres. Take 10 mg of carbon nanospheres and mix with 1 mL of sodium oleate with a concentration of 1 mg / mL, fully disperse by ultrasonic for 1 hour, and then add 1 g of urea and 0.001 mol of cobalt nitrate and 0.0005 mol of nickel nitrate in a molar ratio of 2:1. The mixed solution was stirred at 60°C for 2 hours to obtain a homogeneous solution. Transfer to the autoclave and keep at 120°C for 6 hours. After cooling down to room temperature, rinse with distilled water and ethanol for several times, and bake under vacuum at 60°C for 4 hours. Finally, it was heated to 350 °C in a furnace for 2 hours to obtain carbon nanospheres / NiCo with a core-...

Embodiment 2

[0030] Take 1 g of glucose and add it to 20 mL of distilled water to fully dissolve, and transfer it to a 25 mL reaction kettle. It was then heated to 200°C for 24 hours. After cooling to room temperature, washed with distilled water and ethanol for many times, and dried at 60 °C for 4 hours to obtain carbon nanospheres; take 10 mg of carbon nanospheres and mix with 10 mL of sodium oleate with a concentration of 1 mg / mL, and fully sonicate for 1 hour. After dispersion, 10 g of urea and 0.01 mol of cobalt nitrate and 0.005 mol of nickel nitrate in a molar ratio of 2:1 were added. The mixed solution was stirred at 60°C for 2 hours to obtain a homogeneous solution. Transfer to the autoclave and keep at 180°C for 12 hours. After cooling down to room temperature, rinse with distilled water and ethanol for several times, and bake under vacuum at 60°C for 4 hours. Finally, it was heated to 350 °C in a furnace for 2 hours to obtain carbon nanospheres / NiCo with a core-shell structur...

Embodiment 3

[0032] Take 0.5g of glucose and add it to 20mL of distilled water to fully dissolve, and transfer it to a 25mL reaction kettle. It was then heated to 200°C for 24 hours. After cooling to room temperature, washed with distilled water and ethanol for several times, and dried at 60°C for 4 hours to obtain carbon micro-nanospheres; take 10mg of carbon nanospheres and mix them with 5mL of sodium oleate with a concentration of 1mg / mL, and ultrasonically for 1 hour After sufficient dispersion, 15 g of urea and 0.1 mmol of cobalt nitrate and 0.05 mmol of nickel nitrate in a molar ratio of 2:1 were added. The mixed solution was stirred at 60°C for 2 hours to obtain a homogeneous solution. Transfer to the autoclave and keep at 180°C for 24 hours. After cooling down to room temperature, rinse with distilled water and ethanol for several times, and bake under vacuum at 60°C for 4 hours. Finally, it was heated to 350 °C in a furnace for 2 hours to obtain carbon nanospheres / NiCo with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com