Beneficiation method of high calcium carbonate content type fluorite ore

A beneficiation method and calcium carbonate technology, which are applied in flotation, solid separation and other directions, can solve the problems of low product quality, low concentrate recovery rate, and few applications, and achieve the effect of improving roughing recovery rate and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

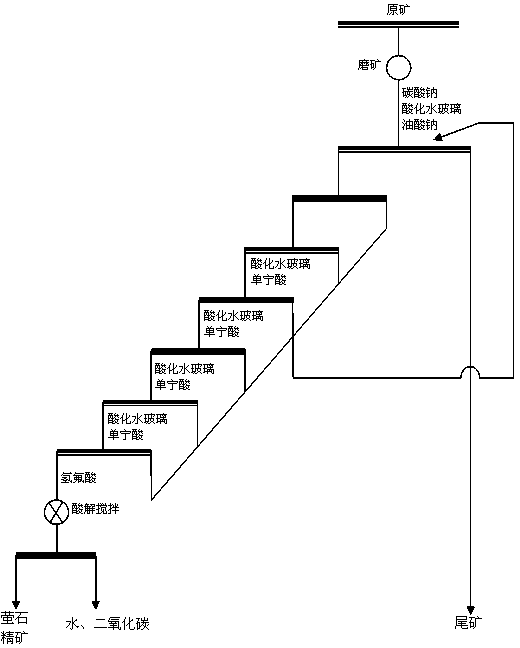

[0024] Such as figure 1 Shown, the beneficiation method of this high calcium carbonate type fluorite ore, its specific steps are as follows:

[0025] (1) Flotation process: First, grind 1 ton of high calcium carbonate fluorite ore until the particle size is less than 74 μm, accounting for 85%, then add the slurry regulator sodium carbonate, and then add gangue inhibitor acidified water glass after 3 minutes. Add collector sodium oleate after 3 minutes and float for 7 minutes to obtain fluorite rough concentrate, in which high calcium carbonate type fluorite ore includes the following mass percentage components: 39.27% fluorite, 21.35% calcium carbonate, The mass ratio of fluorite to calcium carbonate is 1.83; the dosage of sodium carbonate is 1.5kg sodium carbonate per ton of high calcium carbonate fluorite ore; the dosage of acidified water glass is 2.0kg of acidified water per ton of high calcium carbonate fluorite ore Glass; the dosage of sodium oleate is to add 600g of ...

Embodiment 2

[0030] Such as figure 1 Shown, the beneficiation method of this high calcium carbonate type fluorite ore, its specific steps are as follows:

[0031] (1) Flotation process: First, grind the high calcium carbonate fluorite ore until the particle size is less than 74μm, accounting for 92%, then add the slurry regulator sodium carbonate first, and then acidify the water glass with the gangue inhibitor after 3 minutes, and after 3 minutes After 8 minutes of flotation with collector sodium oleate, fluorite rough concentrate can be obtained, in which high calcium carbonate fluorite ore includes the following components in mass percentage: 35.68% fluorite, 25.62% calcium carbonate, fluorite and The mass ratio of calcium carbonate is 1.39; the amount of sodium carbonate is 2kg of sodium carbonate per ton of high calcium carbonate fluorite ore; acidified water glass is a mixed reagent of acid and water glass with a molar ratio of 1:1, the amount of acidified water glass Add 2.5kg of a...

Embodiment 3

[0036] Such as figure 1 Shown, the beneficiation method of this high calcium carbonate type fluorite ore, its specific steps are as follows:

[0037](1) Flotation process: First, grind the high calcium carbonate fluorite ore until the particle size is less than 74μm, accounting for 78%, then add the pulp regulator sodium carbonate first, and then acidify the water glass with the gangue inhibitor after 3 minutes. After 6 minutes of flotation with collector sodium oleate, fluorite rough concentrate can be obtained. The high calcium carbonate type fluorite ore includes the following mass percentage components: fluorite 31.49%, calcium carbonate 16.18%, fluorite and carbonic acid The mass ratio of calcium is 1.95; the dosage of sodium carbonate is to add 1.5kg of sodium carbonate per ton of high calcium carbonate fluorite; The dosage of sodium is to add 300g of sodium oleate per ton of high calcium carbonate fluorite ore;

[0038] (2) Six times of beneficiation process: the fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com