Method for preparing morphology and constitution controllable WO3 nano sheet/g-C3N4 nano composite material

A nanocomposite material and composite material technology are applied in the field of preparation of WO3/g-C3N4 nanocomposite materials to achieve good catalytic effect, promotion of dispersibility and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

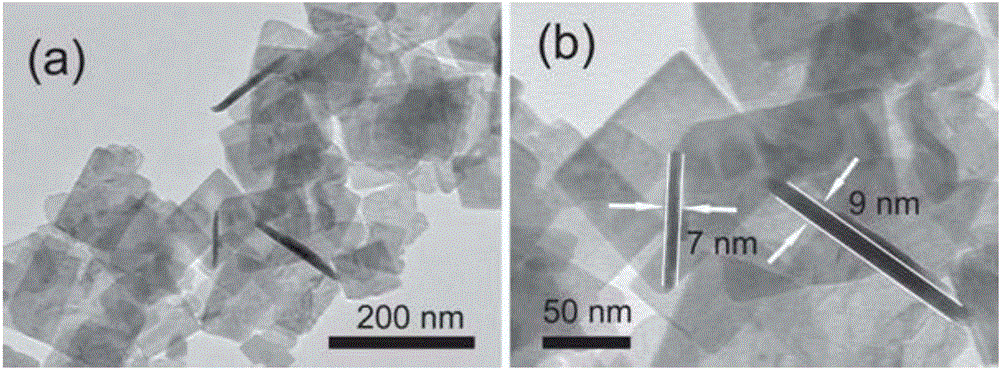

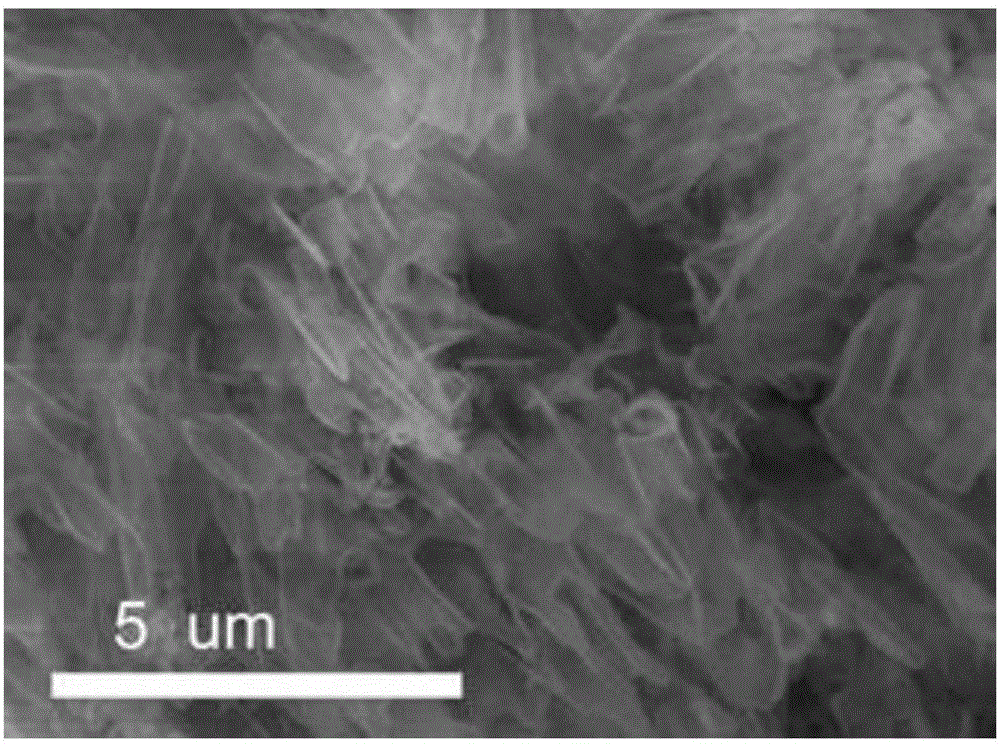

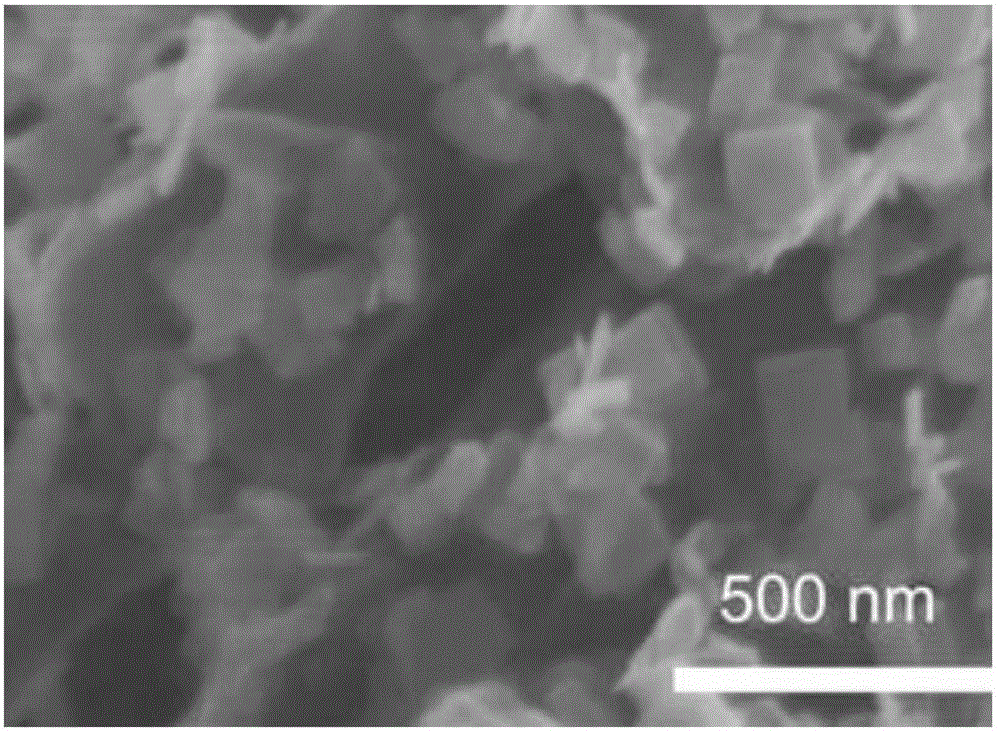

[0031] 1#WO 3 Nanosheet / g-C 3 N 4 The specific preparation steps of nanocomposite materials are as follows:

[0032] (1) g-C 3 N 4 Preparation of nanosheets

[0033] Weigh 2.5g guanidine hydrochloride and 2.5g NH 4 Grind and mix Cl in a mortar evenly, then calcinate in a muffle furnace at 600°C for 2h 45min, and the product obtained is g-C 3 N 4 Nanosheets.

[0034] (2) WO 3 Nanosheet / g-C 3 N 4 Preparation of nanocomposites

[0035] At 25°C, dissolve 250 mg of sodium oleate into 75 mL of nitric acid with a concentration of 4.8 mol / L, and add 25 mg of the above-prepared g-C under stirring conditions. 3 N 4 , stirred for 3 hours, added 2 mL of 0.1mol / L sodium tungstate solution dropwise, kept it warm for 30 minutes, raised the temperature to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheet / g-C 3 N 4 nanocomposites.

Embodiment 2

[0037] 2#WO 3 Nanosheet / g-C 3 N 4 The specific preparation steps of nanocomposite materials are as follows:

[0038] (1) g-C 3 N 4 preparation of

[0039] Same as g-C in embodiment 1 3 N 4 method of preparation.

[0040] (2) WO 3 Nanosheet / g-C 3 N 4 Preparation of nanocomposites

[0041] At 10°C, dissolve 250 mg of sodium oleate into 75 mL of nitric acid with a concentration of 4.8 mol / L, and add 25 mg of the above-prepared g-C under stirring conditions. 3 N 4 , stirred for 3 hours, added 2 mL of 0.1mol / L sodium tungstate solution dropwise, kept it warm for 30 minutes, raised the temperature to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheet / g-C 3 N 4 nanocomposites.

Embodiment 3

[0043] 3#WO 3 Nanosheet / g-C 3 N 4 The specific preparation steps of nanocomposite materials are as follows:

[0044] (1) g-C 3 N 4 preparation of

[0045] Same as g-C in embodiment 1 3 N 4 method of preparation.

[0046] (2) WO 3 Nanosheet / g-C 3 N 4 Preparation of nanocomposites

[0047] At 45°C, dissolve 250 mg of sodium oleate into 75 mL of nitric acid with a concentration of 4.8 mol / L, and add 25 mg of the above-prepared g-C under stirring conditions. 3 N 4 , stirred for 3 hours, added 2 mL of 0.1mol / L sodium tungstate solution dropwise, kept it warm for 30 minutes, raised the temperature to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheet / g-C 3 N 4 nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com