Pollution-free, high-efficiency and long-distance pipe installing and cleaning system

A pipeline installation and cleaning system technology, applied in inorganic/elemental cleaning compositions, cleaning hollow items, detergent compounding agents, etc., can solve the problem of inability to adapt to long-distance flammable and explosive gas pipelines, etc., and achieve obvious social benefits and economic benefits, environmental protection is simple, and the construction period is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

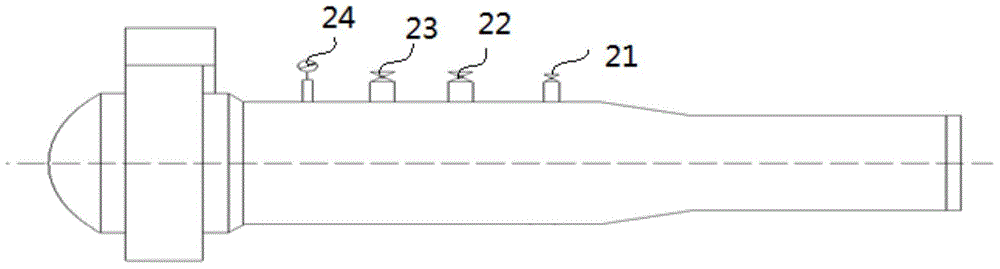

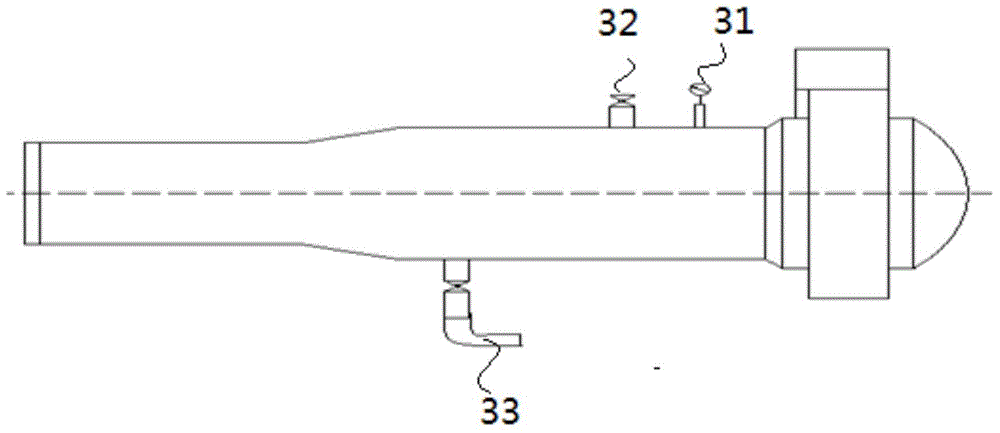

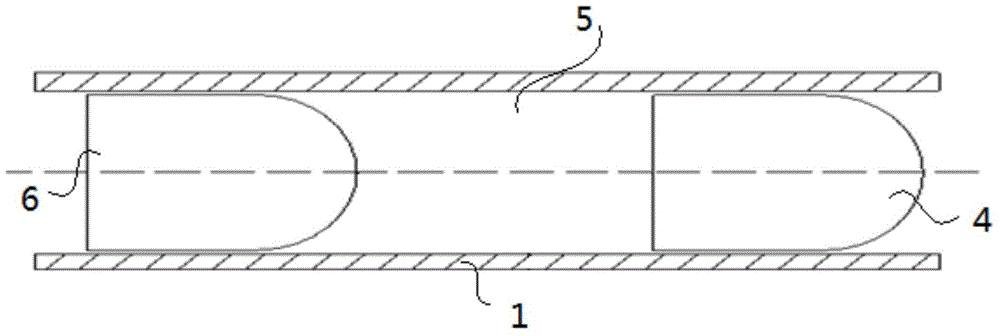

[0037] As shown in the figure, a pollution-free and efficient long-distance pipeline installation cleaning system of the present invention includes a ball delivery device, a ball collection device, a pipe cleaner, a passivating agent and a degreasing agent. The ball delivery device and the ball collection device are used It is installed at both ends of the pipeline 1 to be cleaned for sending pigs and recycling pigs; the ball delivery device includes a section of first temporary pipe, and one end of the first temporary pipe is installed and connected to the end of the pipeline 1 to be cleaned. The other end of the first temporary pipe is provided with a blind plate, which can be closed / opened. The first vent valve 21, the liquid injection valve 22, the gas source valve 23, and the first vent valve 21, the liquid injection valve 22, the gas source valve 23 and the first temporary pipe Pressure gauge 24 (e.g. figure 1 (Shown), the air compressor is connected to the ball delivery d...

Embodiment 2

[0059] The cleaning method of the long-distance pipeline in this embodiment is basically the same as that in Example 1, except that the formula of the passivator is expressed in mass fraction as sodium nitrite 2%, trisodium phosphate 0.5%, and water 97.5%; as in the pipeline If the grease pollution is serious, the degreasing agent needs to increase the dosage of the agent. The formula is expressed in mass fraction as follows: sodium tripolyphosphate 3.5%, sodium carbonate 2%, sodium hydroxide 1.5%, sodium borate 0.4%, ethylenediaminetetraacetic acid Sodium 0.2%, sodium oleate 0.1%, sodium lauryl sulfate 0.1%, alkylphenol polyoxyethylene ether 0.1%, water 92.1%. The passivating agent and degreasing agent of the present invention are both water-based degreasing agents. The subsequent environmental protection treatment is simple and environmentally friendly. The formula of the degreasing agent makes the degreasing effect of the degreasing agent efficient, which not only ensures the...

Embodiment 3

[0061] The cleaning method for long-distance pipelines in this embodiment is basically the same as that in embodiment 1, except that the formula of passivating agent is expressed in mass fraction as sodium nitrite 3%, trisodium phosphate 1%, and water 96%; The formula is expressed by mass fraction as sodium tripolyphosphate 3.0%, sodium carbonate 1.5%, sodium hydroxide 1.0%, sodium borate 0.3%, disodium edetate 0.1%, sodium oleate 0.08%, dodecyl sulfuric acid Sodium 0.08%, alkylphenol polyoxyethylene ether 0.07%, water 93.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com