Range hood cleaning agent and preparation method thereof

A technology for cleaning agents and range hoods, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of chapped peeling, skin damage, damage, etc., and achieves a suitable consistency, easy to clean, and cost-effective. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

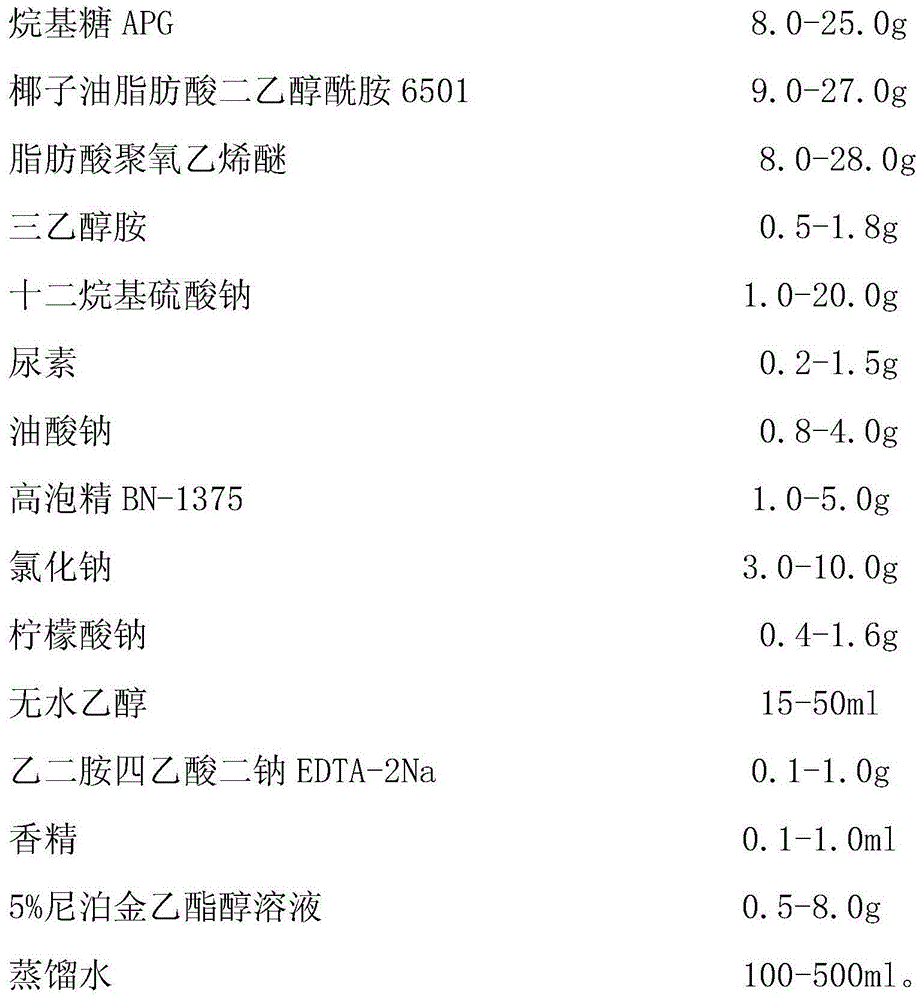

Method used

Image

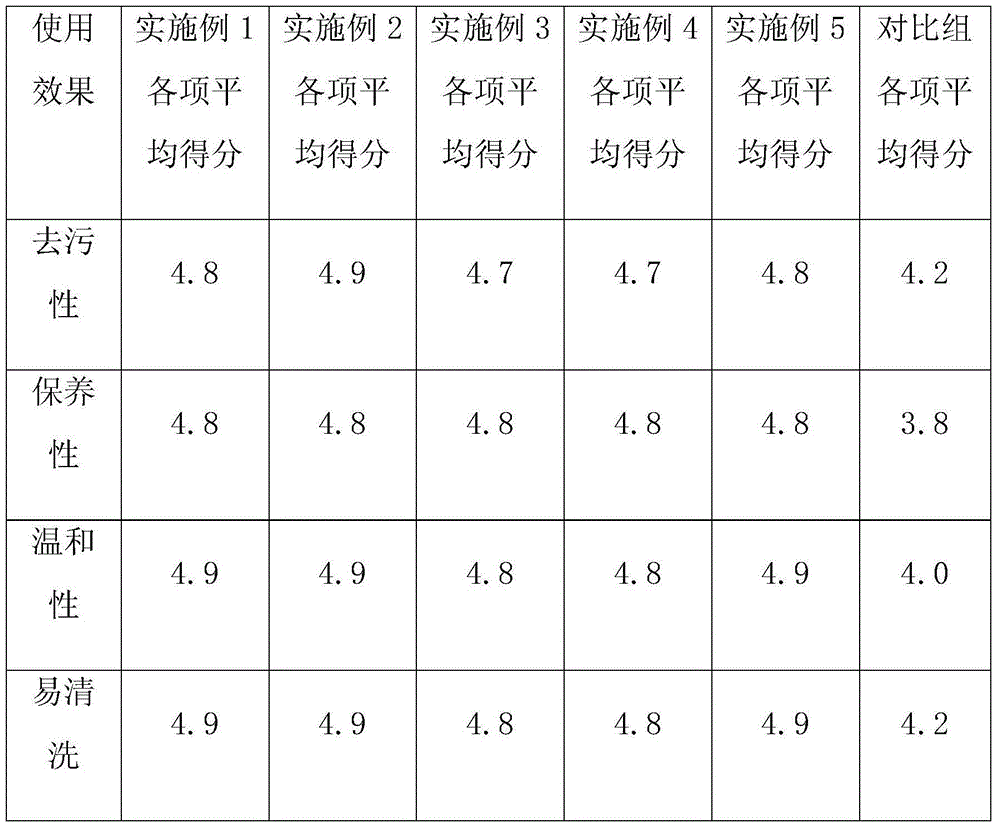

Examples

Embodiment 1

[0028] The range hood cleaning agent described in the present embodiment is made by following steps:

[0029] Step 1: Take 300ml of distilled water in a large beaker and heat it in a water bath at 80°C. Add 1.5g of sodium citrate to the water and keep stirring. After the dissolution is complete, add 25.0g of fatty alcohol polyoxyethylene ether sodium sulfate AESA, 10.0 g alkyl glycoside APG, 24.0 g of coconut oil fatty acid diethanolamide 6501, after the dissolution is complete, add 14.0 g of fatty acid polyoxyethylene ether;

[0030] Step 2: Take 1.0g of triethanolamine and add it to the solution. After it is completely dissolved, add 8.0g of sodium lauryl sulfate, then add 0.8g of urea. After it is completely dissolved, add 1.0g of sodium oleate, continue stirring, and add 30ml Ethanol, then add 0.5g edetate disodium EDTA-2Na;

[0031] Step 3: After stirring evenly, add 3.0g of high foaming essence BN-1375, 0.5ml of essence, 5.0g of salt, and 1.0g of 5% ethylparaben alcohol...

Embodiment 2

[0033] Range hood cleaning agent described in the present embodiment is made by following steps:

[0034] Step 1: Take 480ml of distilled water in a large beaker and heat it in a water bath at 70°C. Add 0.6g of sodium citrate to the water and keep stirring. After the dissolution is complete, add 40.0g of fatty alcohol polyoxyethylene ether sodium sulfate AESA, 20.0 g alkyl glycoside APG, 10.0g coconut oil fatty acid diethanolamide 6501, after the dissolution is complete, add 18.0g fatty acid polyoxyethylene ether;

[0035] Step 2: Take 0.7g of triethanolamine and add it into the solution. After it is completely dissolved, add 10.0g of sodium lauryl sulfate, then add 0.9g of urea. Ethanol, then add 0.4g disodium edetate EDTA-2Na;

[0036] Step 3: After stirring evenly, add 3.0g of high-foaming essence BN-1375, 0.6ml of essence, 6.0g of salt, and 1.0g of 5% ethylparaben alcohol solution to obtain the range hood cleaner. Wherein said essence can be one or more in lemon essence,...

Embodiment 3

[0038] Range hood cleaning agent described in the present embodiment is made by following steps:

[0039]Step 1: Take 100ml of distilled water in a large beaker and heat it in a water bath at 80°C. Add 0.4g of sodium citrate to the water and keep stirring. After the dissolution is complete, add 15.0g of fatty alcohol polyoxyethylene ether sodium sulfate AESA, 8.0 g alkyl glycoside APG, 9.0g coconut oil fatty acid diethanolamide 6501, after the dissolution is complete, add 8.0g fatty acid polyoxyethylene ether;

[0040] Step 2: Take 0.5g of triethanolamine and add it into the solution. After it is completely dissolved, add 1.0g of sodium lauryl sulfate, then add 0.2g of urea. Ethanol, then add 0.1g ethylenediaminetetraacetic acid disodium EDTA-2Na;

[0041] Step 3: After stirring evenly, add 1.0g of high-foaming essence BN-1375, 0.1ml of essence, 3.0g of salt, and 0.5g of 5% ethylparaben alcohol solution to obtain the range hood cleaner. Wherein said essence can be one or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com