Mineral collecting agent and flotation process of copper sulphide ore

A technology of copper sulfide ore and collector, applied in the field of mineral collector and flotation process of copper sulfide ore, can solve the problems of insufficient copper recovery rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

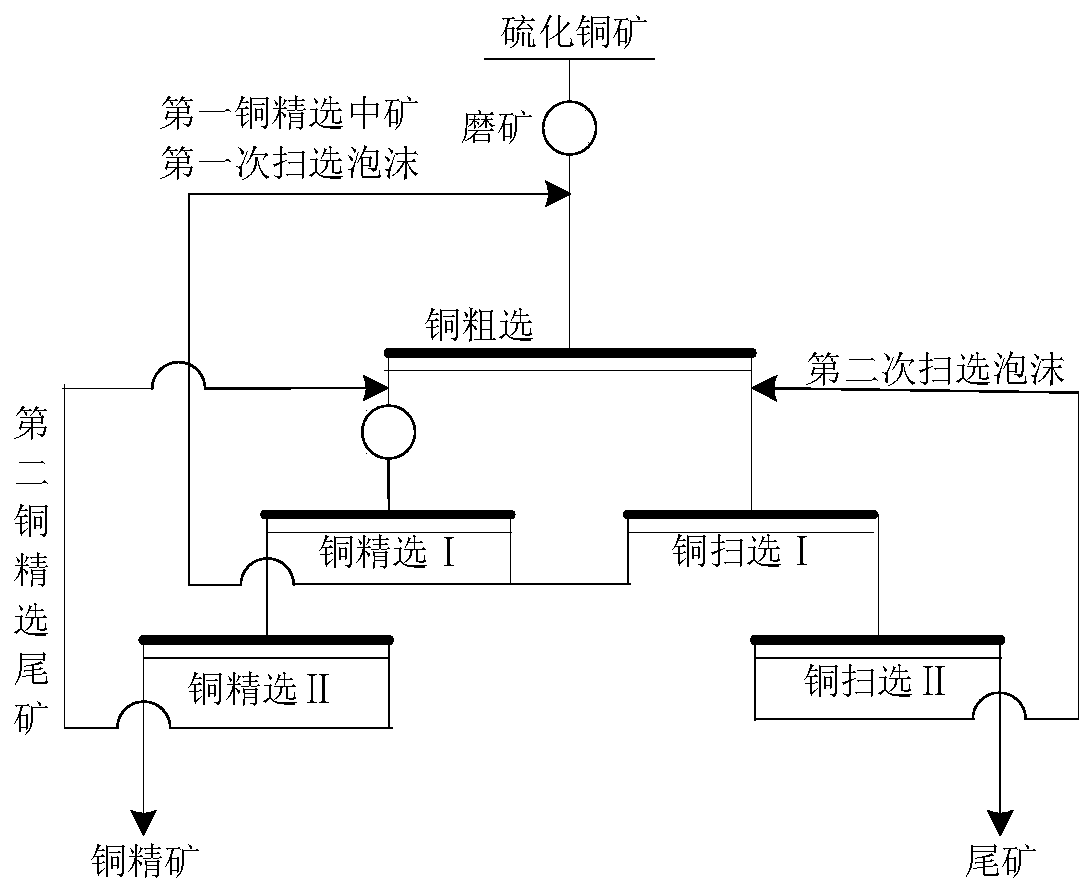

Method used

Image

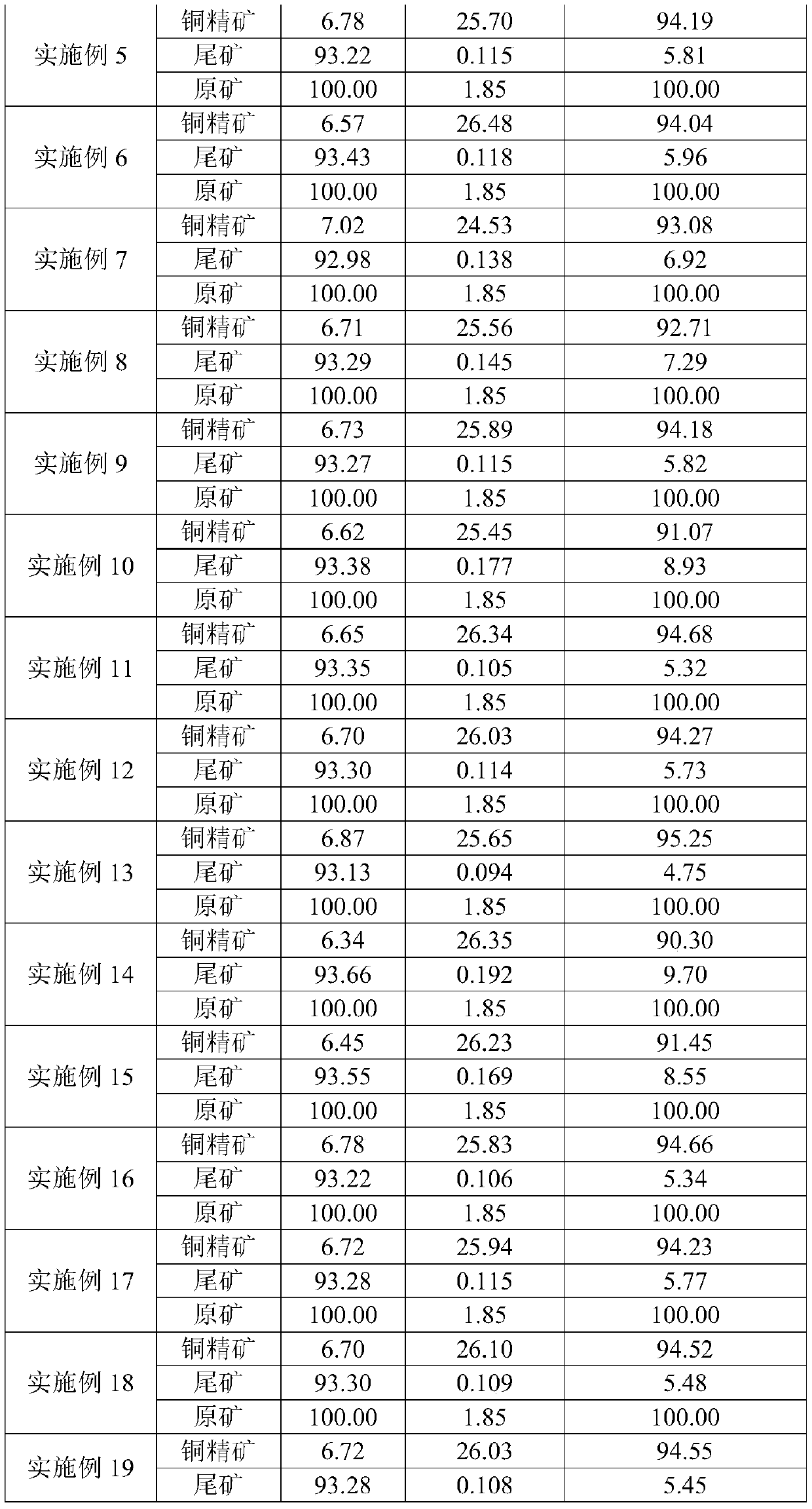

Examples

Embodiment 1

[0053]Experimental design: Take copper sulfide ore with a copper grade of 1.85, add water and grind the copper sulfide ore to obtain the first slurry with a solid content of 35%, add 750g Na 2 CO 3 (the addition amount of the medicament is calculated in tons of ore, the same below). In the first ore slurry, in terms of mass percentage, the ore particles with a particle size less than 0.074mm account for 60% of the total amount of ore. The first pulp, 40g first collector and 20g C 10 h 17 The OH is mixed and stirred for 3 minutes, and the copper roughing is carried out. The flotation time is 3 minutes, and the roughing copper concentrate and the roughing copper tailings are obtained. Wherein, the weight ratio of butyl xanthate, butylammonium black drug, and ethylthiocarbamate in the first collector is 7:1.5:1.5.

[0054] Grinding the roughed copper concentrate to obtain the second pulp. In the second ore pulp, in terms of mass percentage, copper concentrate particles with ...

Embodiment 2

[0059] The difference between embodiment 2 and embodiment 1 is that the solid content of the first pulp is 30%, the copper grade of copper concentrate and tailings is analyzed, and the yield and copper recovery rate of copper concentrate and tailings are calculated.

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 1 is that the solid content of the first pulp is 40%, the copper grade of copper concentrate and tailings is analyzed, and the yield and copper recovery rate of copper concentrate and tailings are calculated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com