Color separation device for single mineral separation

A color sorting device and single-mineral technology, which is applied in sorting, solid separation, filtering and screening, etc., can solve the problem that the separation of small particles and single minerals is difficult to meet the actual needs of scientific research and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

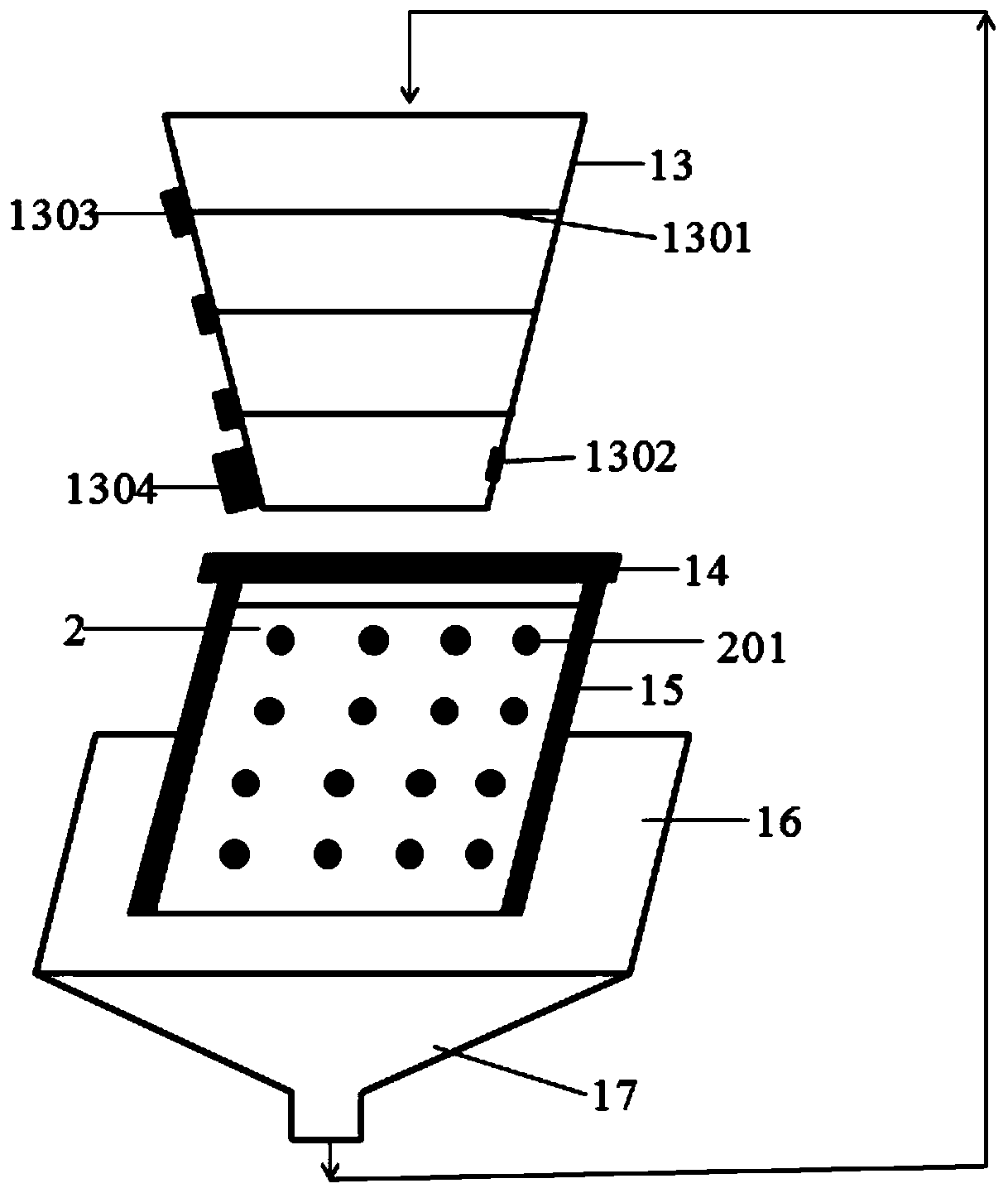

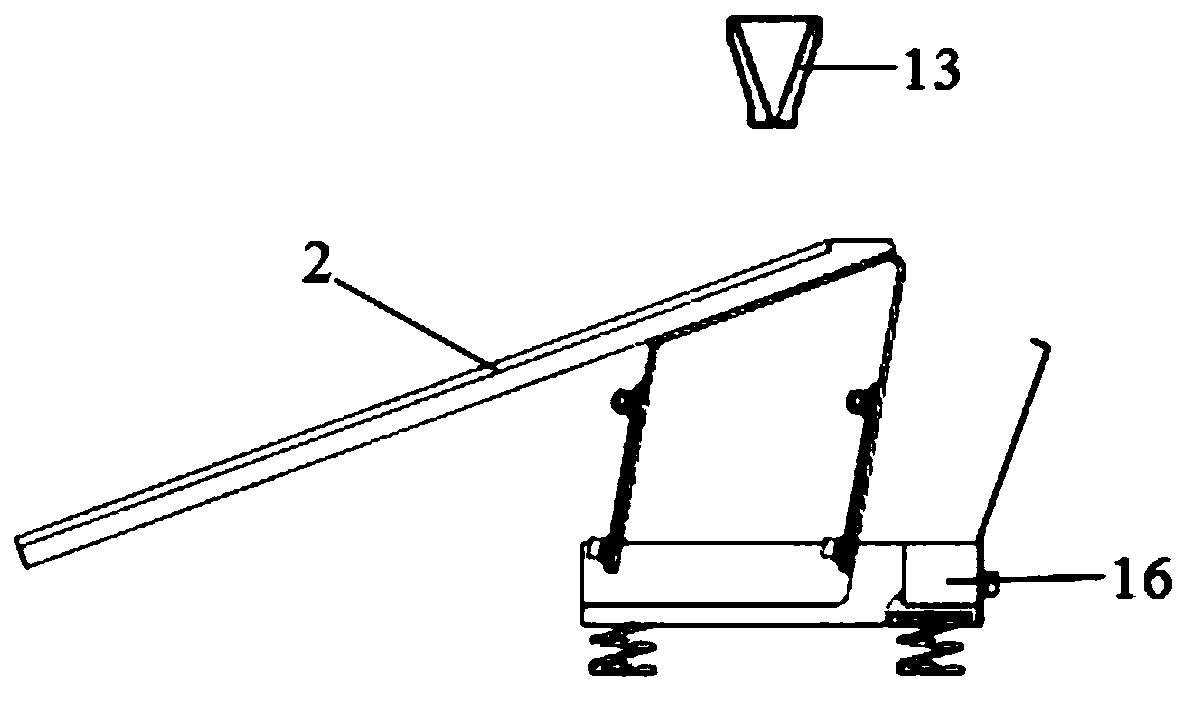

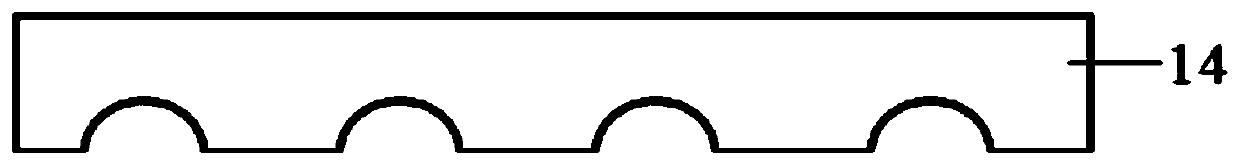

[0057] The structural diagram of the distributing device of the present embodiment is as follows: figure 1 and 2 As shown, the distributing device includes a first hopper 13 , a vibrating device 16 and a collecting hopper 17 . The first hopper 13 is arranged on the top of the vibrating device 16, the perforated plate 2 is arranged between the vibrating device 16 and the first hopper 13, the vibrating device 16 is detachably and fixedly connected with the perforated plate 2, and the collecting hopper 17 is arranged under the vibrating device 16, Used to collect the ore material falling from the perforated plate 2.

[0058] Three layers of sieve plates 1301 are placed inside the first hopper 13 , and the sieve plates 1301 are used to screen the mineral material falling from the first hopper 13 , and the three sieve plates 1301 are all perpendicular to the central axis of the first hopper 13 . Different sieve plates 1301 have different mesh numbers, and the mesh numbers of the ...

Embodiment 2

[0087] The vibrating device of the color sorting device used for single mineral separation in this embodiment does not have a scraper 14 and a scraper slide rail 15 , and through the vibration of the inclined perforated plate 2 , redundant mineral particles fall into the collecting hopper 17 . The sieve plate 1301 , photoelectric sensor 1302 and controller 1303 are not provided in the first hopper 13 , and the original ore particles are finely screened by manual operation, and then spread on the porous plate 2 through the first hopper 13 .

[0088] Other structures of the color sorting device in this embodiment are the same as those of the color sorting device in Embodiment 1.

Embodiment 3

[0090] The distributing device of the color sorting device used for single mineral separation in this embodiment includes a first hopper 13 and a second hopper 19, no sieve plate is set in the second hopper 19, and the second hopper 19 is arranged beside the first hopper 13 The bottom of the collecting hopper 17 is connected to the top inlet of the second hopper 19 through a negative pressure air path, and when the vacancy rate of the perforated plate 2 is greater than a preset value, the ore falling into the collecting hopper 17 is recovered to the second hopper 19 for re-use. Sow on the perforated plate 2. When in use, manually move the vibrating device and the perforated plate 2 below the second hopper 19, and wait for the second sowing.

[0091] Other structures of the color sorting device in this embodiment are the same as those of the color sorting device in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com