Environmental-friendly glue sulfur and molybdenum mineral collecting agent, preparation method and application

An environmentally friendly, collector technology, applied in solid separation, flotation and other directions, can solve the problems of poor selectivity of nickel and molybdenum minerals, environmental damage, etc., and achieve the effects of not easy to deteriorate, long quality guarantee time, and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

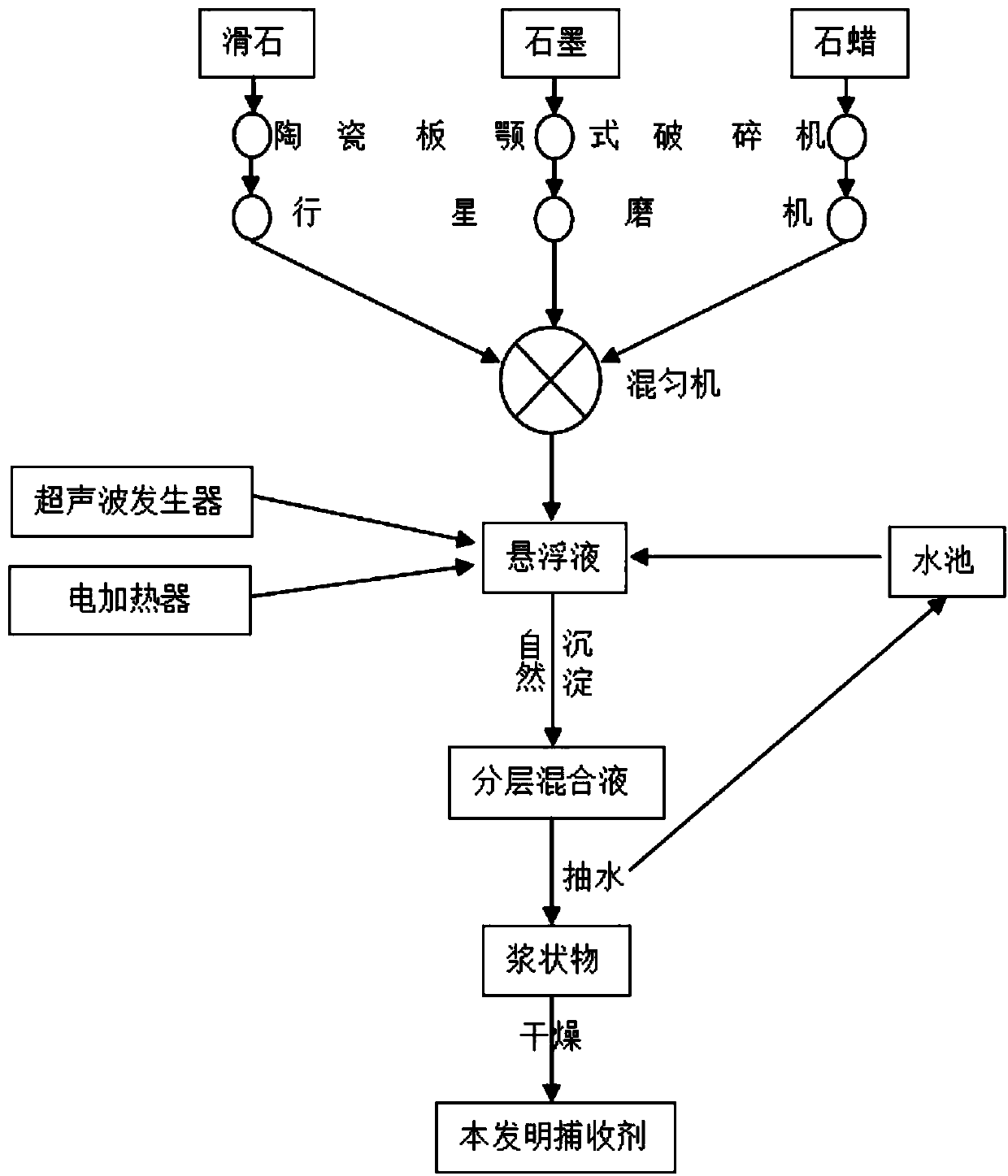

[0027] Add 100 parts of talc with an average particle size of 249nm, 15 parts of graphite with an average particle size of 285nm, and 4 parts of paraffin wax with an average particle size of 332nm into a mixer and mix thoroughly, and prepare the above nano-mineral mixture with 11 times the mass of water as a dispersion medium The suspension was fully dispersed after 50W ultrasonic treatment at a constant temperature of 42°C for 13 minutes, left to stand for 0.5h, and then treated with 270W ultrasonic for 8min, after standing for 25.5h, the upper layer of clear water was drawn out, and the residual slurry was dried to obtain the collector of the present invention.

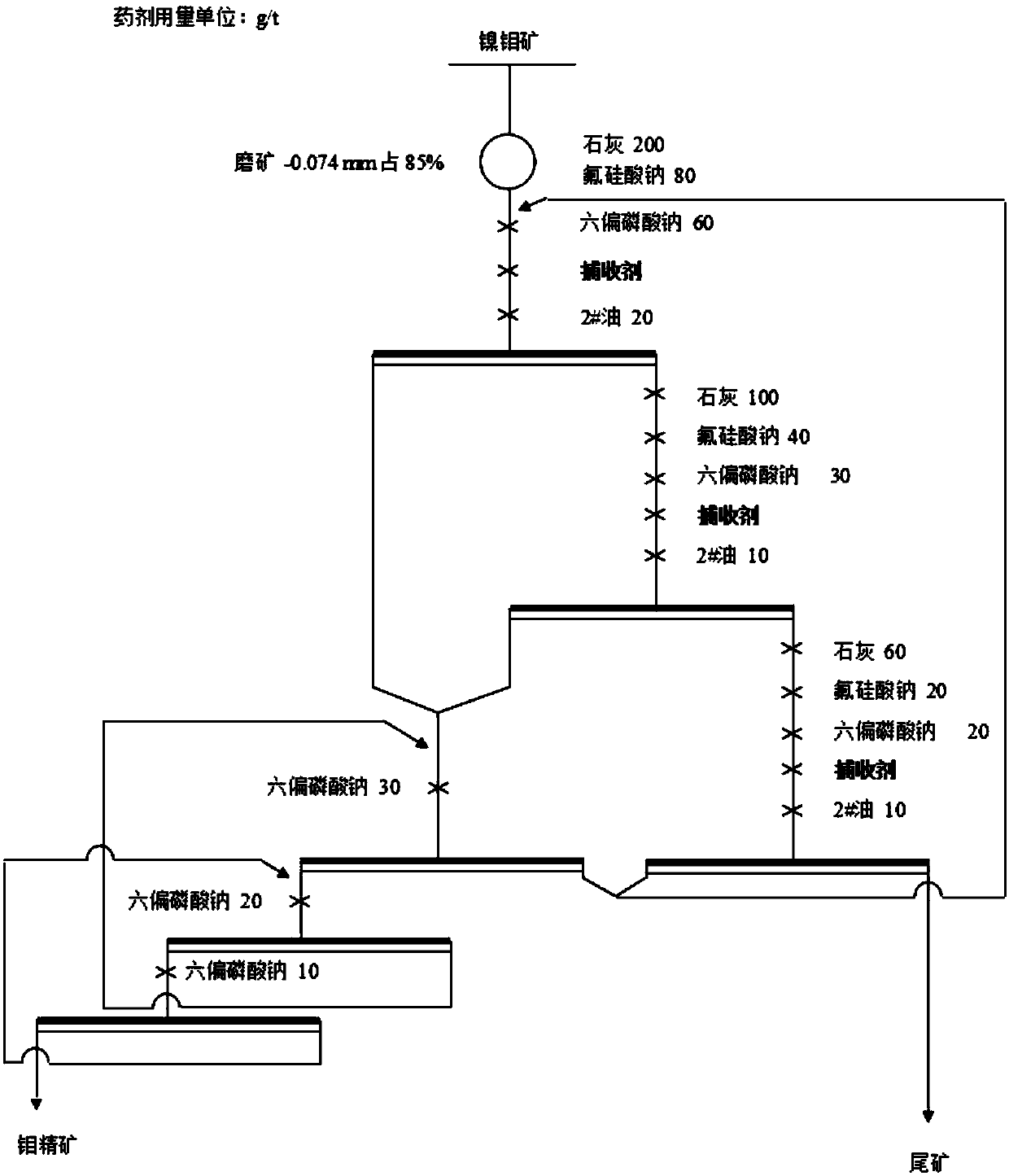

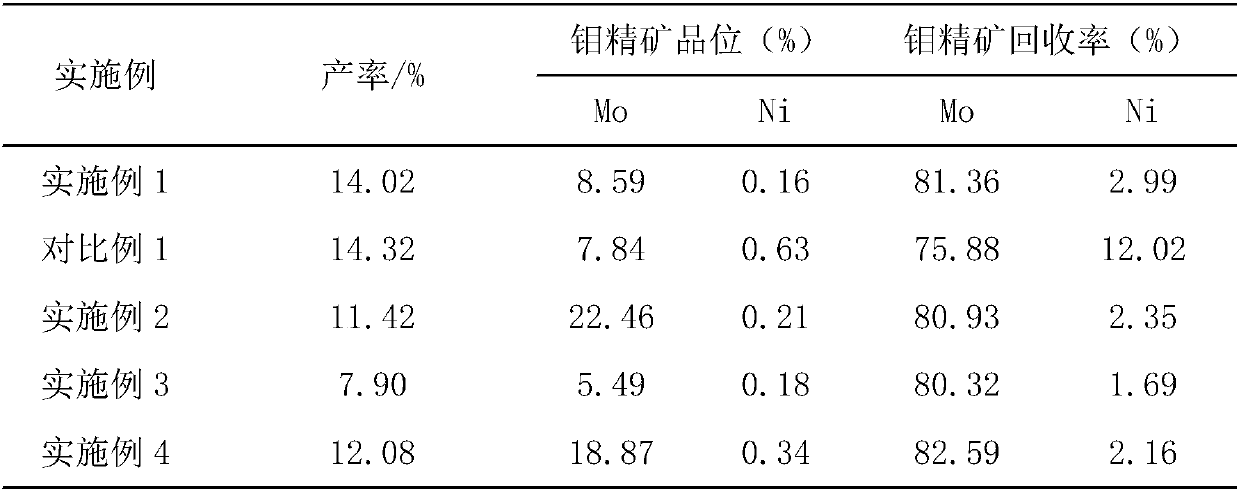

[0028] A flotation test of a nickel-molybdenum ore in Zhangjiajie, Hunan was carried out using the above collectors. The raw ore contains 1.48% molybdenum and 0.75% nickel, and the molybdenum mainly exists in the form of amorphous colloidal sulfur molybdenum minerals. A small-scale closed-circuit test of "two roughi...

Embodiment 2

[0034] Add 100 parts of talc with an average particle size of 275nm, 10 parts of graphite with an average particle size of 265nm, and 25 parts of paraffin wax with an average particle size of 300nm into a mixer and mix them, and use the above-mentioned nano-mineral mixture and 28 times the mass of water as a dispersion medium to prepare a suspension The solution was fully dispersed after 150W ultrasonic treatment at a constant temperature of 35°C for 7.5min, left to stand for 2h, then 195W ultrasonically treated for 12.5min, after standing for 18h, the upper layer of clear water was drawn out, and the residual slurry was dried to obtain the collector of the present invention.

[0035] The flotation test of a nickel-molybdenum ore in Zunyi District, Guizhou was carried out using the above collectors. The raw ore contains 3.17% molybdenum and 1.02% nickel, and the molybdenum mainly exists in the form of amorphous colloidal sulfur molybdenum minerals. A small-scale closed-circuit...

Embodiment 3

[0037] Add 100 parts of talc with an average particle size of 240nm, 60 parts of graphite with an average particle size of 310nm, and 16 parts of paraffin with an average particle size of 320nm into a mixer for mixing, and use the above-mentioned nano-mineral mixture and 18 times the mass of water as a dispersion medium to prepare a suspension After 120W ultrasonic treatment at a constant temperature of 50°C for 3 minutes to fully disperse the solution, let it stand for 3.5 hours, and then use 245W ultrasonic treatment for 10 minutes. After standing for 28 hours, take out the upper layer of clear water and dry the residual slurry to obtain the collector of the present invention.

[0038] A flotation test of a nickel-molybdenum ore in Yunnan was carried out using the above collectors. The raw ore contains 0.54% molybdenum and 0.84% nickel, and the molybdenum mainly exists in the form of amorphous colloidal sulfur molybdenum minerals. A small-scale closed-circuit test of "two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com