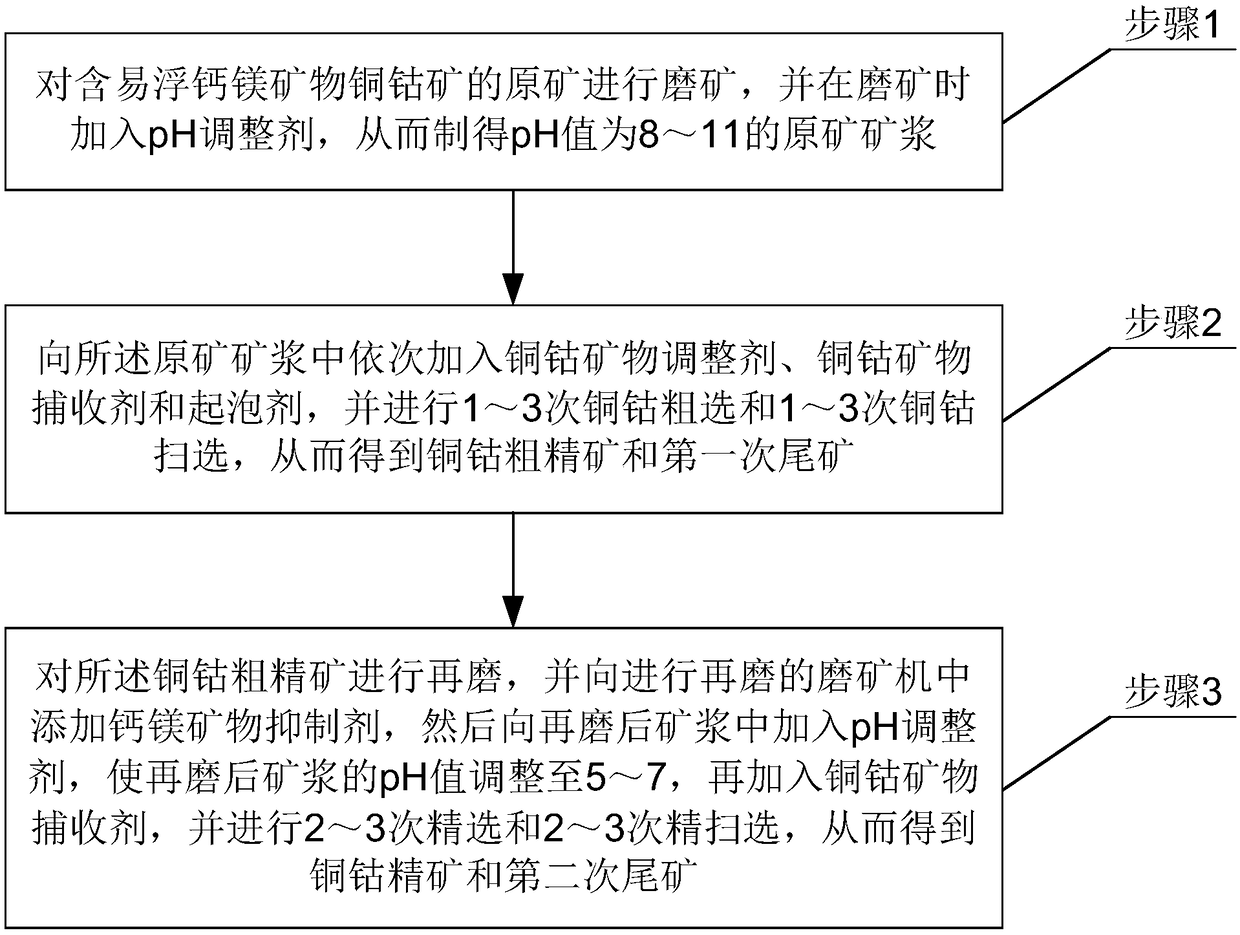

Mineral separation method for copper-cobalt ore containing easy-to-float calcium magnesium minerals

A beneficiation method and technology for copper-cobalt ore, which are applied in flotation, solid separation, etc., can solve the problems of large circulation of medium ore, high content of gangue in copper-cobalt concentrate, difficult operation and management, etc., so as to reduce the content of gangue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

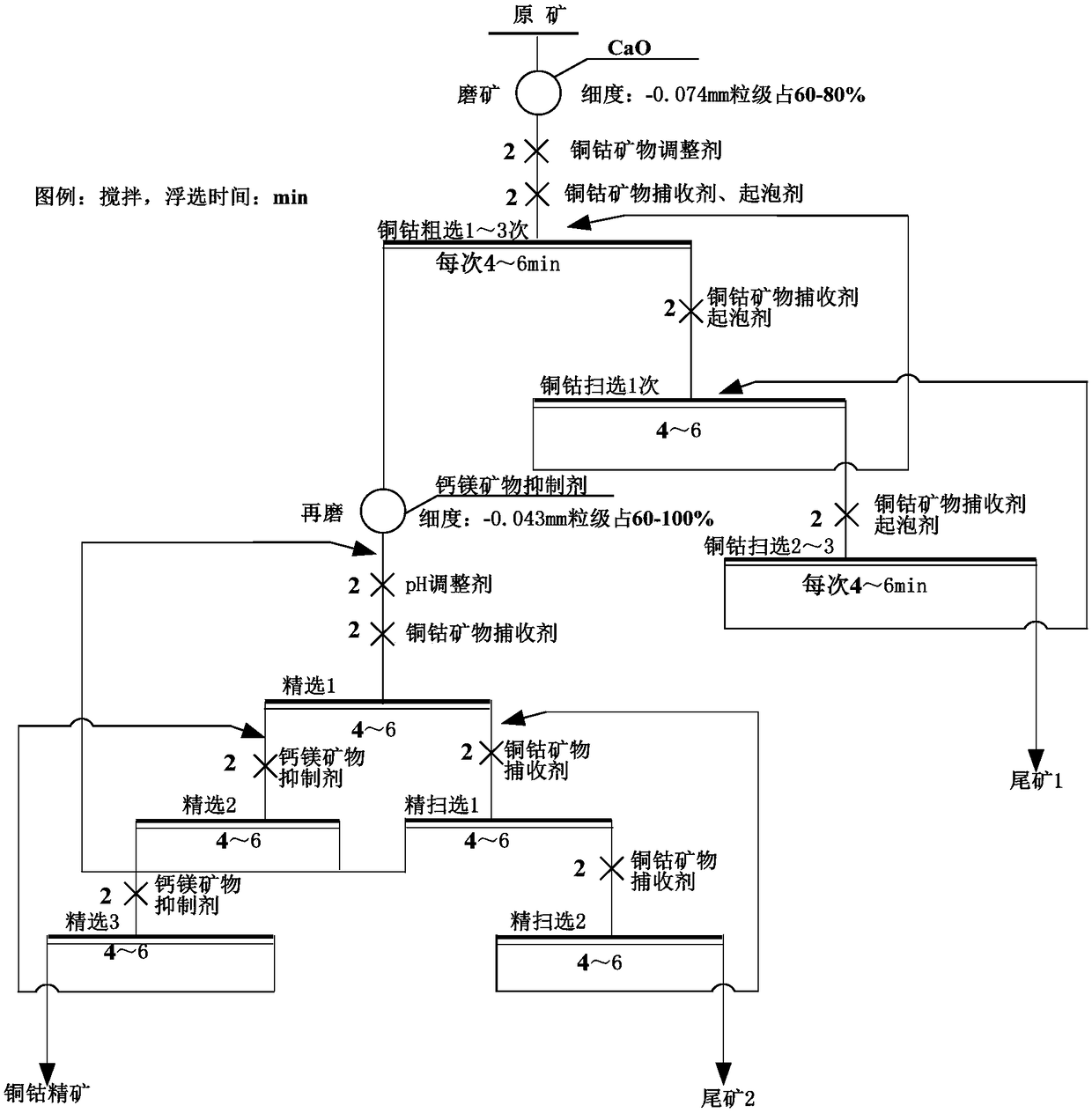

[0031] (1) In step 1, the pH regulator is preferably CaO, and the grinding fineness is preferably -0.074mm, accounting for 60-80%.

[0032] (2) In step 2, the copper-cobalt mineral regulator is Na 2 S, at least one of NaHS, and the amount of the copper-cobalt mineral regulator is 10-1000g / t raw ore (in this field, "10-1000g / t raw ore" refers to the use of 10-1000g per ton of raw ore; In this document, the dosages of this form all represent this meaning, but the values are different, so no more details). The dosage of the copper-cobalt mineral regulator is the dosage for the first copper-cobalt roughing, and the copper-cobalt mineral regulator does not need to be added in the rest of the flotation process. The flotation time of each copper-cobalt roughing and each copper-cobalt sweeping is 4-6 minutes.

[0033] (3) In step 2, the copper-cobalt mineral collector is mixed with a xanthate collector and a targeted collector, and wherein the xanthate collector consumption is 10 ...

Embodiment 1

[0046] The raw ore of a copper-cobalt ore containing easy-to-float calcium-magnesium minerals contains 0.32% copper and 0.34% cobalt, and the copper-containing minerals in the raw ore are mainly chalcopyrite, chalcocite, bornite, copper blue, sulfur Copper-cobalt ore, etc. The cobalt-containing minerals in the raw ore are mainly sulfur-copper-cobalt ore, cobalt-containing pyrite, cobalt, etc. The gangue minerals in the raw ore are mainly dolomite, talc, chlorite, pyroxene, quartz, etc. The total amount of calcium and magnesium minerals contained in the raw ore accounts for about 60% of the total weight of the raw ore, that is, this is a typical copper-cobalt ore containing easy-to-float calcium and magnesium minerals.

[0047] like figure 2 As shown, a method for beneficiation of copper-cobalt ore containing easy-floating calcium-magnesium minerals is used for beneficiation of copper-cobalt ores containing easy-floating calcium-magnesium minerals. Specifically, the following ...

Embodiment 2

[0055] A raw ore containing copper-cobalt ore, an easy-to-float calcium-magnesium mineral, contains 1.28% copper and 0.52% cobalt, and the copper-containing minerals in the raw ore are mainly chalcopyrite, chalcocite, copper blue, blue chalcocite, Tetrahedrite, sulfur copper cobalt ore, malachite, pyrite, etc., the gangue minerals in the raw ore are mainly quartz, feldspar, dolomite, mica, chlorite, talc, serpentine, apatite, etc., the raw ore The total amount of calcium and magnesium minerals contained in the ore accounts for about 42% of the total weight of the original ore.

[0056] like figure 2 As shown, a method for beneficiation of copper-cobalt ore containing easy-floating calcium-magnesium minerals is used for beneficiation of copper-cobalt ores containing easy-floating calcium-magnesium minerals. Specifically, the following steps may be included:

[0057] Step B1. Perform wet grinding on the raw ore containing copper-cobalt ore, which is an easy-to-float calcium-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com