Flotation process for reducing fluorine content in copper sulfide concentrate

A copper sulfide and concentrate technology, applied in flotation, solid separation and other directions, can solve the problem of acid-making catalyst pulverization, corrosion of acid-making equipment and wastewater treatment equipment, excessive fluorine content in copper sulfide concentrate, and increased maintenance costs, etc. problems, to achieve the effect of suppressing floatability, reducing entrainment, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

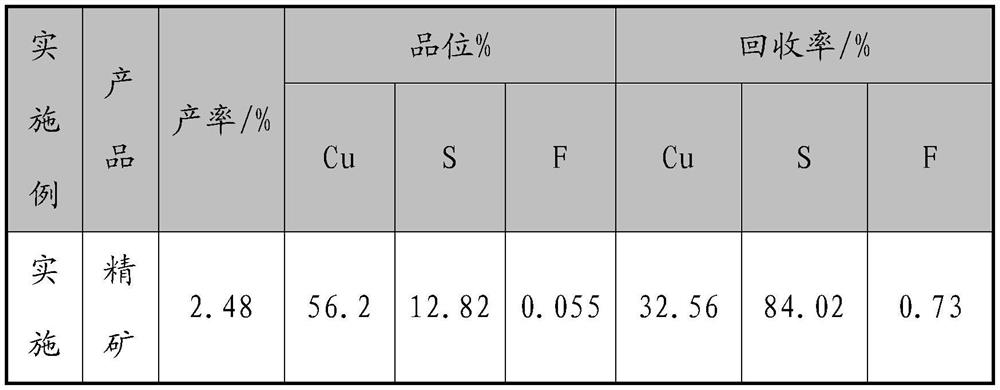

Embodiment 1

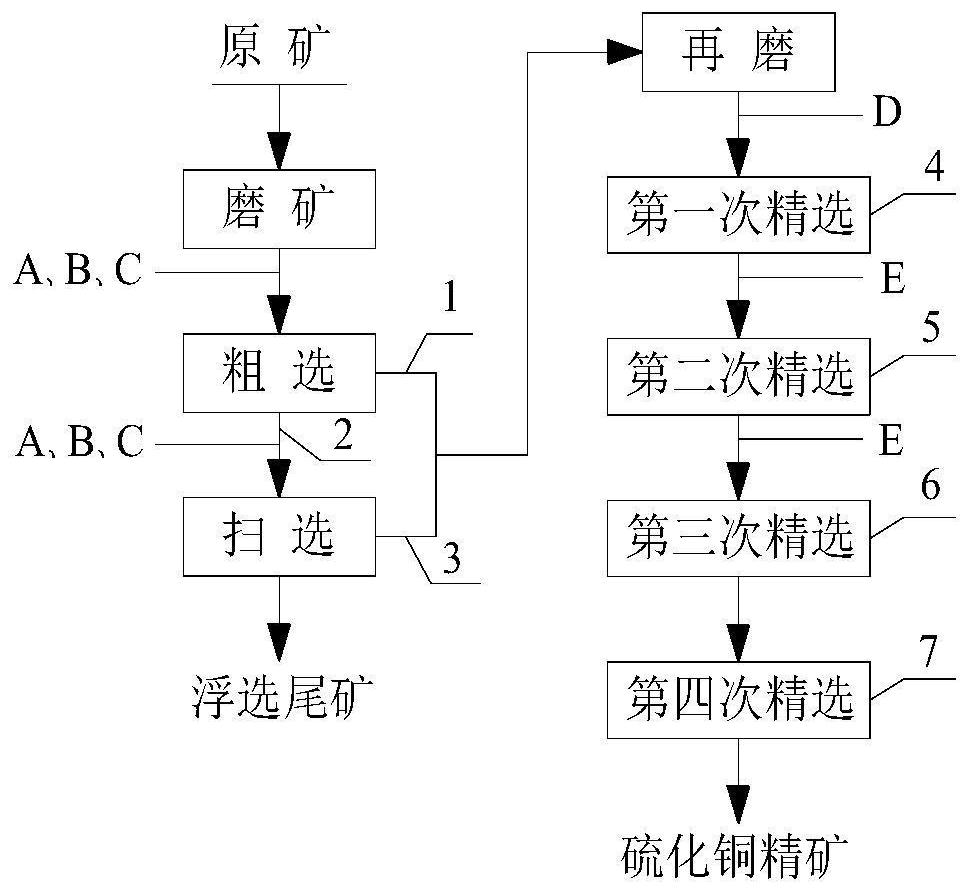

[0028] A foreign large-scale oxygen-sulfur mixed copper mine has a copper content of 4.11%, a sulfur content of 0.26% and a fluorine content of 0.19%. The copper minerals are mainly chalcocite (1.27%), malachite (5.90%), a small amount of sill malachite (0.57%), chalcopyrite (0.19%) and traces of cerulis and cuprite; other metal minerals Mainly pyrite (0.95%), limonite (0.80%), hematite (0.67%); gangue minerals are mainly quartz, dolomite, feldspar, mica, chlorite, fluorapatite, etc. . flotation process such as figure 1 As shown, A: butyl xanthate; B: butyl ammonium black medicine; C: 2# oil; D: clear water; E: dispersant; 1: copper sulfide roughing concentrate; 2: copper sulfide roughing tailings ;3: Copper sulfide scavenging rough concentrate; 4: The first selection of tailings; 5: The second selection of tailings; 6: The third selection of tailings; 7: The fourth selection of tailings .

[0029] The raw ore is added to the ball mill for rough grinding, the concentration...

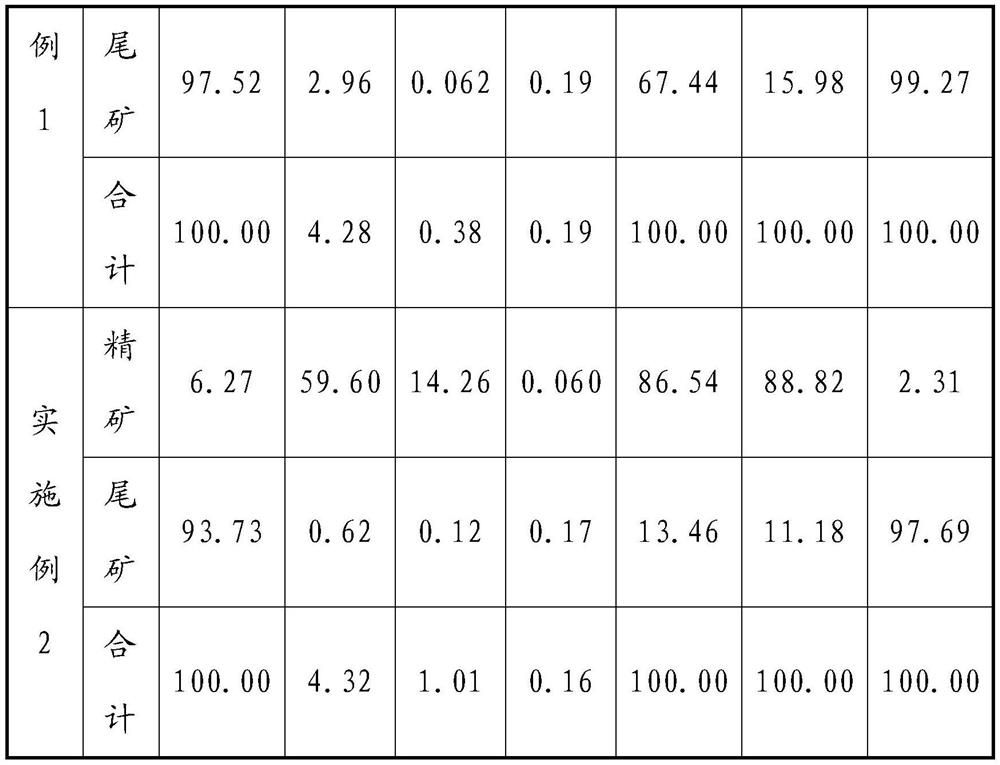

Embodiment 2

[0031] In an extra-large copper sulfide mine abroad, the raw ore contains 4.32% copper, 1.01% sulfur and 0.16% fluorine. The main copper minerals are chalcocite, followed by bornite, which contains a small amount of natural copper, cuprite, malachite and silicomaalachite. Gangue minerals are mainly feldspar, followed by mica minerals and quartz. The target minerals are embedded with fine particle size, which is easy to entrain fluorine-containing minerals. using as figure 1 The process shown is processed, and the specific steps include:

[0032] The raw ore is added to the ball mill for rough grinding. The rough grinding concentration is 75%, and the final rough grinding fineness is -0.074mm, accounting for 66%; the grinding product enters the roughing operation, and the flotation slurry concentration is 32%. Add collector and foaming agent in the process. According to the dry weight of raw ore, add collector butyl xanthate 110g / t and butylammonium black medicine 25g / t per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com