Antimony oxide mineral and quartz flotation separation method

A separation method and antimony oxide technology, applied in flotation, solid separation and other directions, can solve the problems of not finding a better recovery method, low grade, etc., and achieve the effect of less chemical dosage and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0021] The first example of the flotation separation method of antimony oxide mineral and quartz according to the present invention comprises the following steps:

[0022] 1. Mineral raw materials:

[0023] The content of antimony in the mineral raw materials used is 0.86%, the content of silicon is 13.28%, the content of calcium carbonate is 5.69%, the content of magnesium oxide is 4.72%, and the content of iron is 12.43%. According to the phase analysis, the oxidation rate of antimony is 83.74%. It exists in the form of salt and quartz, iron mainly exists in the form of limonite, calcium and magnesium minerals mainly exist in the form of carbonate, and a small amount of aluminum-containing minerals.

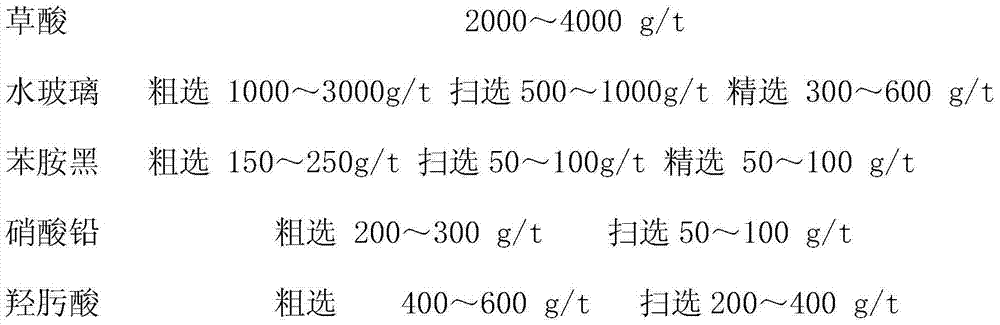

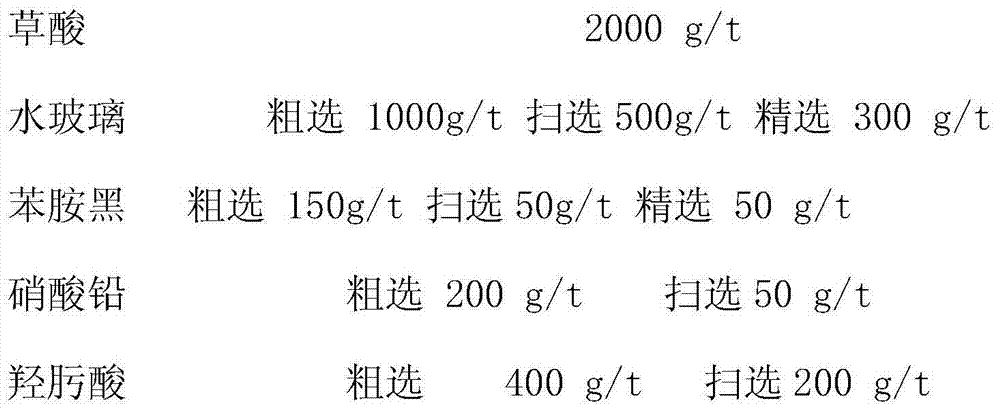

[0024] 2. Flotation agents and operating conditions:

[0025]

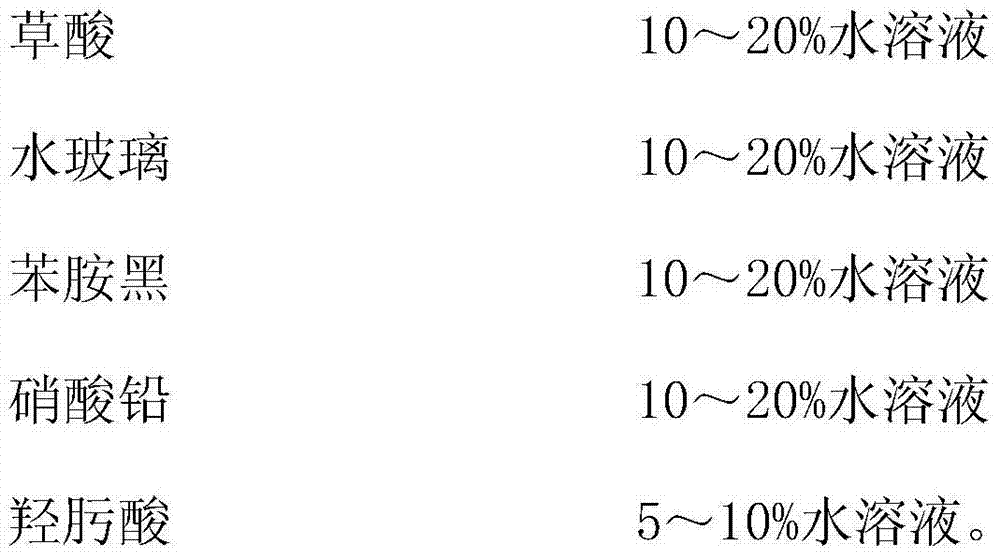

[0026] When in use, the medicament is first prepared into the following weight percent concentrations:

[0027]

[0028]

[0029] During the flotation process, after the ore is ground until the mineral m...

no. 2 example

[0031] The second example of the flotation separation method of antimony oxide mineral and quartz according to the present invention comprises the following steps:

[0032] 1. Mineral raw materials:

[0033] The content of antimony in the mineral raw materials used is 1.72%, 14.66% silicon, 3.31% calcium carbonate, 4.07% magnesium oxide, and 17.50% iron. The phase analysis shows that the antimony oxidation rate is 81.40%, and silicon is mainly composed of silicon It exists in the form of salt and quartz, iron mainly exists in the form of limonite, calcium and magnesium minerals mainly exist in the form of carbonate, and a small amount of aluminum-containing minerals.

[0034] 2. Flotation agents and operating conditions:

[0035]

[0036] When in use, the medicament is first prepared into the following weight percent concentrations:

[0037]

[0038] During the flotation process, after the ore is ground until the mineral monomers are dissociated, the pH value of the sl...

no. 3 example

[0040] The third example of the flotation separation method of antimony oxide mineral and quartz according to the present invention comprises the following steps:

[0041] 1. Mineral raw materials:

[0042] The content of antimony in the mineral raw materials used is 2.53%, the content of silicon is 17.80%, the content of calcium carbonate is 9.10%, the content of magnesium oxide is 6.21%, and the content of iron is 18.57%. According to the phase analysis, the oxidation rate of antimony is 81.32%. It exists in the form of salt and quartz, iron mainly exists in the form of limonite, calcium and magnesium minerals mainly exist in the form of carbonate, and a small amount of aluminum-containing minerals.

[0043] 2. Flotation agents and operating conditions:

[0044]

[0045]

[0046] When in use, the medicament is first prepared into the following weight percent concentrations:

[0047]

[0048] During the flotation process, after the ore is ground until the mineral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com