Nozzle used for ore flotation equipment

A mineral flotation and nozzle technology, applied in flotation, solid separation, etc., can solve problems affecting the operation rate of flotation equipment, poor wear resistance of nozzles, and short service life, so as to reduce maintenance labor workload and improve Operational efficiency and the effect of improving beneficiation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

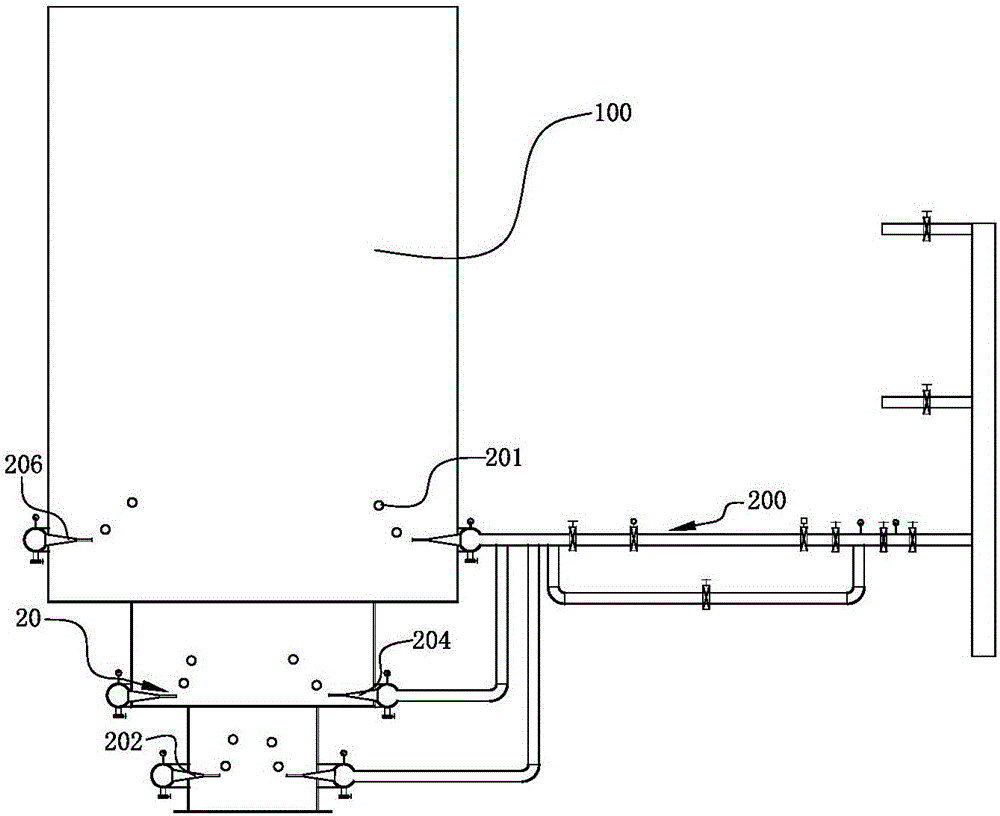

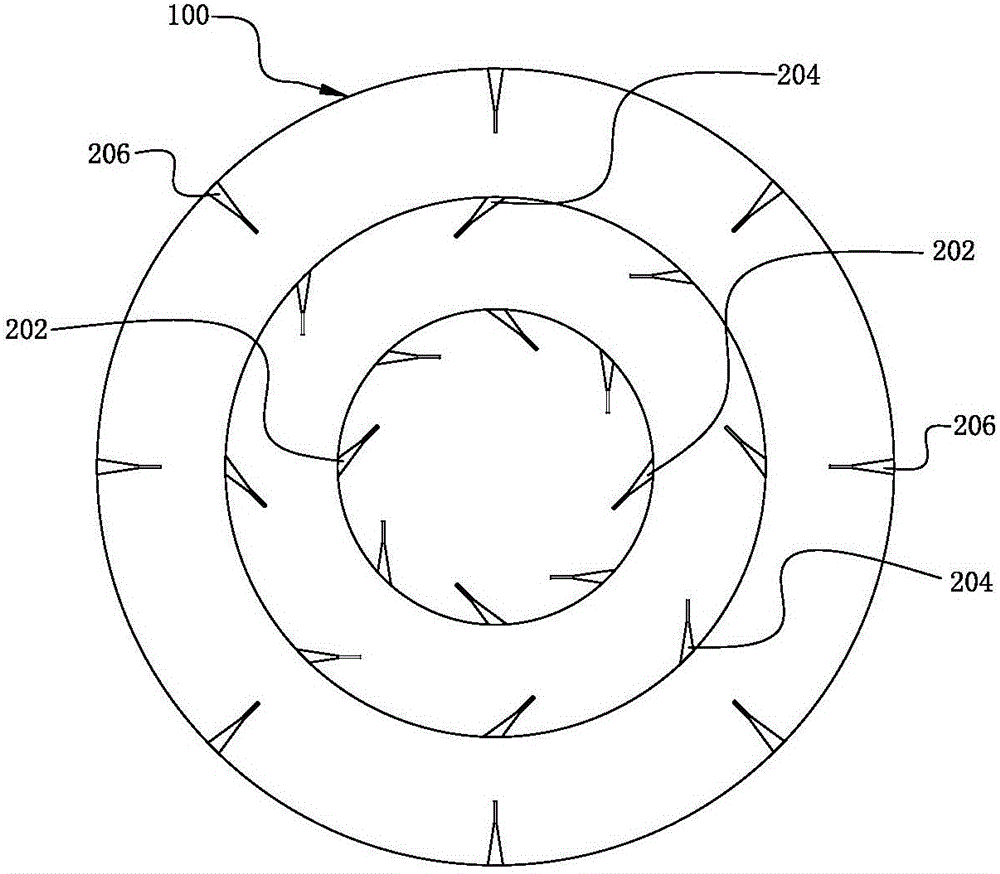

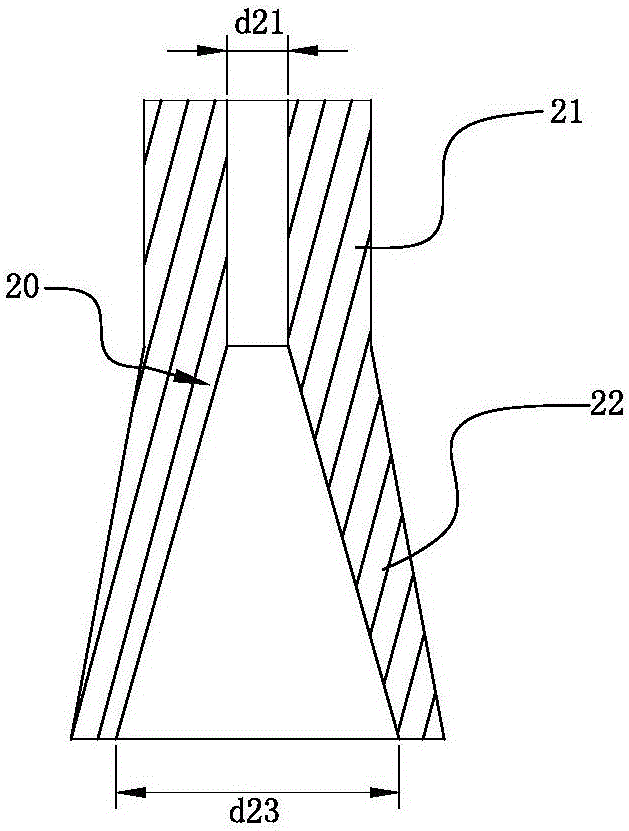

[0025] Please refer to figure 1 , figure 2 and image 3 The material of the tungsten alloy used for the nozzle 20 of the mineral flotation device in the first embodiment includes tungsten carbide and nickel, and the mass percentage of the tungsten carbide is 80.0%-85.0%, and the mass percentage of the nickel is 11.0%-13.0%. The hardness of the tungsten alloy material is HRA 89.0-91.0. Adding nickel in the tungsten carbide alloy can improve the toughness and thermal fatigue resistance of the tungsten carbide alloy nozzle 20 , and can also improve the corrosion resistance and oxidation resistance of the tungsten carbide alloy nozzle 20 . Through experimental comparison, it is found that when the mass percentage of nickel in the tungsten carbide alloy is 11.0%-13.0%, the service life of the tungsten alloy nozzle 20 used in the mineral flotation equipment is the best, and the average service life can reach 2-3 years.

[0026] The tungsten alloy material used for the nozzle 20 ...

Embodiment 2

[0042] Such as Figure 4 As shown, the injector nozzle 30 of the jet flotation machine (not shown in the figure) is cylindrical, and the injection hole of the tungsten alloy nozzle 30 is conical, and the aperture d32 at the widest part of the injection hole is 40-42mm, and the aperture d33 at the narrowest The diameter of the tungsten alloy nozzle 30 is 29-31mm. After the action of the ore slurry and the flotation agent, it is sprayed out from the narrowest part of the injection hole. The structure of the tungsten alloy nozzle 30 can effectively increase the injection pressure of the nozzle 30 and increase the injection range, thereby improving the separation between the ore slurry and the air bubbles. touch. The flotation agent has a certain corrosion effect, and the tungsten alloy material nozzle 30 of the present invention is wear-resistant and corrosion-resistant, and the average service life of the nozzle is significantly improved.

[0043] The average service life test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com