Big-open-loop small-closed-loop mud flotation method of oxidized ore

A technology for oxidizing ore and flotation, applied in flotation, solid separation and other directions, can solve the problems of inability to become a product, poor beneficiation index, low concentrate grade, etc., and achieve convenient operation, low production cost, concentrate grade and recovery. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

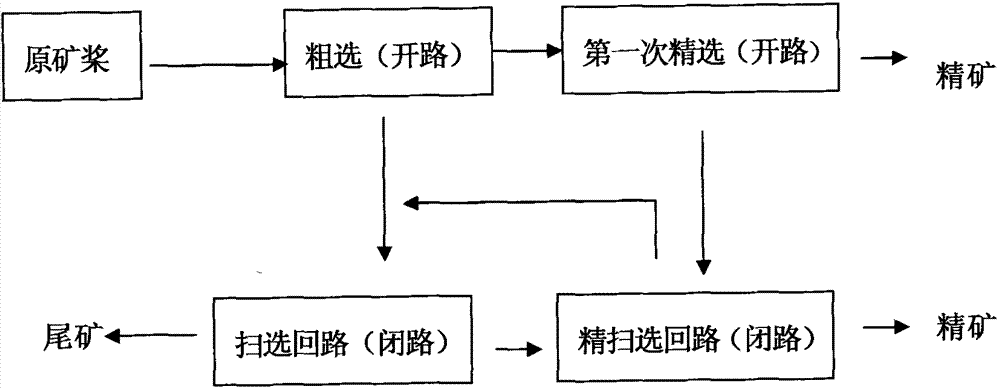

[0014] For a low-grade zinc oxide ore, the raw ore pulp contains about 40% mud (less than 10 microns) and about 5% zinc. The zinc minerals are mainly zinc carbonate, zinc silicate, ferrite and hydrozincite. The zinc oxidation rate 60%~95%, gangue minerals are mainly carbonate minerals such as mica and calcite. Whole mud flotation is adopted, and the agent system of vulcanization-xanthate beneficiation or vulcanization-fatty amine beneficiation is used. When the concentration of the selected ore pulp is about 40%, an open-circuit roughing is firstly carried out, and the rough-selected foam product is subjected to an open-circuit selection to obtain the final concentrate. Return in turn to form a closed circuit. The foam in the scavenging 1 is combined with the product in the first-selected tank and then fine-swept twice to obtain the final concentrate, and the product in the tank is returned to the scavenging operation for re-election. The beneficiation index that the zinc oxi...

Embodiment 2

[0016] The zinc oxide ore treated in this example contains only about 2% zinc, and the oxidation rate is 98%. Zinc minerals are mainly zinc carbonate, zinc silicate, ferrite and hydrozincite, and gangue minerals are mainly silicate minerals such as quartz. Whole mud flotation is adopted, and the agent system of vulcanization-xanthate beneficiation or vulcanization-fatty amine beneficiation is used. When the concentration of the selected pulp is about 37%, the grinding fineness is 95%-200 mesh, and the pulp contains about 27% of mud (less than 10 microns). To obtain the final concentrate, the product in the rough-selected tank enters three times of sweeping, and the foam products of the sweeping are returned in turn to form a closed circuit. The final concentrate and the product in the tank are returned to the scavenging operation for re-election. The beneficiation index that the zinc oxide concentrate grade is greater than 35% and the recovery rate is greater than 93% can be...

Embodiment 3

[0018] This example involves whole mud flotation beneficiation of low-grade gneiss scheelite ore. The raw ore grade is about 0.3%. In the case of using conventional scheelite flotation agents, one open-circuit roughing, one open-circuit sweeping, and then directly throw the tailings. The obtained coarse concentrate is subjected to five closed-circuit separations and three fine sweeps. , the ore dressing index with a concentrate grade of more than 60% and a recovery rate of more than 82% can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com