Automatic collection device and method for waste steel balls and sundries in discharged materials of ball mill

An automatic collection and ball mill technology, applied in chemical instruments and methods, grain processing, solid separation, etc., can solve problems such as the impact of subsequent beneficiation operations, and achieve the effect of improving resource utilization, simple production, and improving beneficiation indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

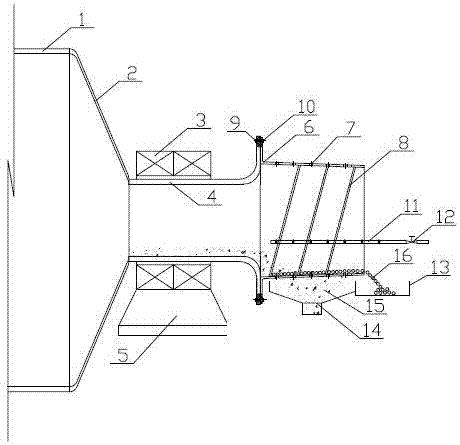

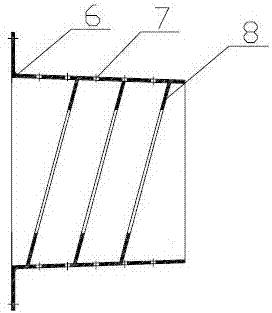

[0021] Embodiment: Before the grinding operation in the concentrator starts, the ball mill barrel 1 is filled with grinding medium steel balls of different sizes in a certain proportion, and the filling amount of the steel balls is about 30%-45% of the volume of the mill. When the ball mill starts to rotate at a certain speed driven by power, the ore to be ground is continuously fed into the ball mill barrel 1, and new steel balls are properly added into the mill barrel 1 at the same time. Afterwards, the ore and steel balls are thrown, rolled, and ground with the rotating mill cylinder. During this operation, the ore is ground, and the steel balls are also ground or broken during this process. The ore 15, finely ground or broken scrap steel balls and debris 16 are discharged from the ball mill cylinder 1 through the ball mill discharge cylinder 4 and enter the conical cylindrical screen 6, and the conical cylindrical screen 6 rotating with the ball mill cylinder 1 continues C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com