Flotation process adopting flotation column to regrading scheelite instead of flotation machine

A flotation column and flotation machine technology, applied in the field of scheelite flotation, can solve the problems of unstable beneficiation index, low degree of automation, high labor intensity, etc., to improve labor environment, reduce labor intensity, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

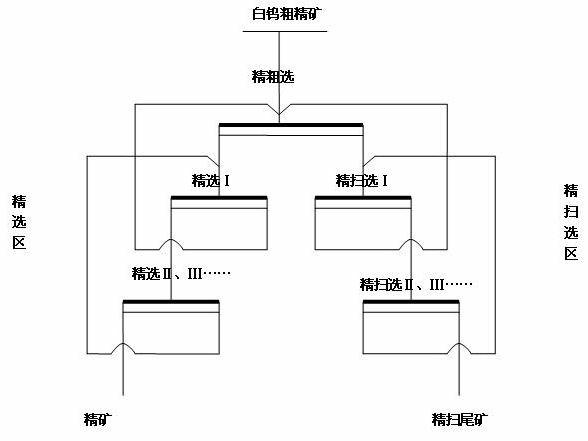

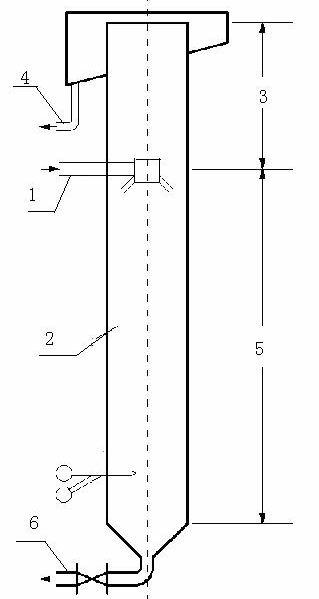

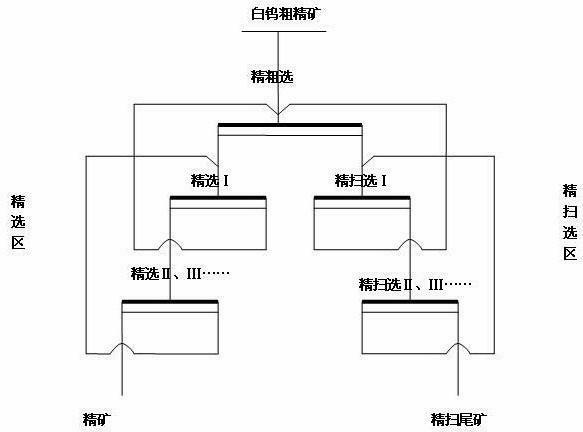

[0018] Such as figure 1 As shown, a scheelite beneficiation process that uses flotation columns instead of flotation machines is to use flotation column technology in the scheelite beneficiation after roughing scheelite ore to conduct several times of beneficiation of rough concentrate , the selected tailings are also fine-swept several times using flotation columns to obtain higher-grade scheelite concentrates. The steps are as follows:

[0019] 1. Rough concentrate is obtained from scheelite after rough separation, and the coarse concentrate is concentrated into about 70% ore pulp. Add caustic soda at about 200±10 grams per ton of coarse concentrate, heat to 92-95°C, and keep warm for two Hours off the drug.

[0020] 2. The heated and demedicated coarse concentrate enters a stirring tank for slurry adjustment, so that the concentration of the ore slurry is between 20% and 30%;

[0021] 3. Then enter the flotation column for fine and rough selection, and the fine and rough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com