Beneficiation method for improving flotation indexes of microfine-grained scheelite

A mineral processing method and technology of scheelite, applied in flotation, solid separation, etc., can solve the problems of difficult and efficient flotation of fine-grained scheelite, achieve the effect of strengthening surface hydrophobicity and improving mineral processing indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

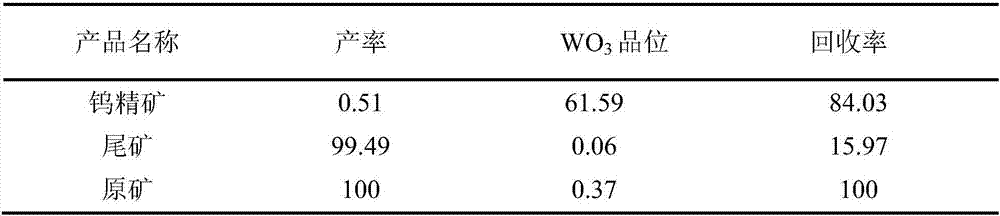

Embodiment 1

[0024] Sodium dodecyl sulfonate was prepared to a concentration of 9×10 -3 The mol / L solution was added into a high-speed mixing barrel, and stirred at a speed of 5000 rpm for 8 minutes to prepare charged microbubbles with charged surfaces. Grind the scheelite ore to -0.074mm and the content is 80%, add 1500g / t sodium carbonate, 500g / t inhibitor carboxylated chitosan, 120g / t 731 oxidized paraffin wax soap for slurry adjustment, and then carry out flotation coarse The rougher concentrate and rougher tailings are obtained. The inhibitor carboxylated chitosan was added to the roughing concentrate for 5 times of beneficiation to obtain concentrate 1, the dosage of inhibitor for beneficiation 1 was 300g / t, the last 4 beneficiations were blank beneficiation, and the beneficiation of middle ore was returned sequentially . Add 80g / t collector 731 oxidized paraffin soap to the roughing tailings for the first scavenging, add 40g / t collector 731 oxidized paraffin soap to the scavenging...

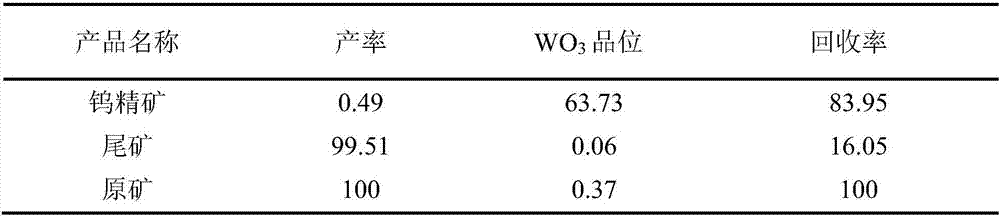

Embodiment 2

[0029] Sodium lauryl sulfate was formulated to a concentration of 8.1×10 -3 The mol / L solution was added into a high-speed mixing barrel, and stirred at a speed of 6400 rpm for 5 min to prepare charged microbubbles with charged surfaces. Grind the scheelite ore to -0.074mm and the content is 90%, add 1200g / t sodium carbonate, 800g / t inhibitor carboxylated chitosan, 180g / t 731 oxidized paraffin wax soap for slurry preparation, and then carry out flotation Roughing to obtain roughing concentrate and roughing tailings. Inhibitor carboxylated chitosan was added to the rough beneficiation concentrate for 5 times of beneficiation to obtain concentrate 1, the amount of inhibitor carboxylated chitosan for the first beneficiation was 200g / t, and the last four beneficiation was blank beneficiation , the selected medium mines are returned in order. Add 100g / t collector 731 oxidized paraffin soap to the roughing tailings for the first scavenging, add 50g / t collector 731 oxidized paraffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com