Gangue depressor for flotation of high-magnesium and low-nickel polymetallic ore

A polymetallic ore and inhibitor technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of nickel and copper, high impurity magnesia, etc., achieve high nickel and copper grade, less impurity magnesia, and weak inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

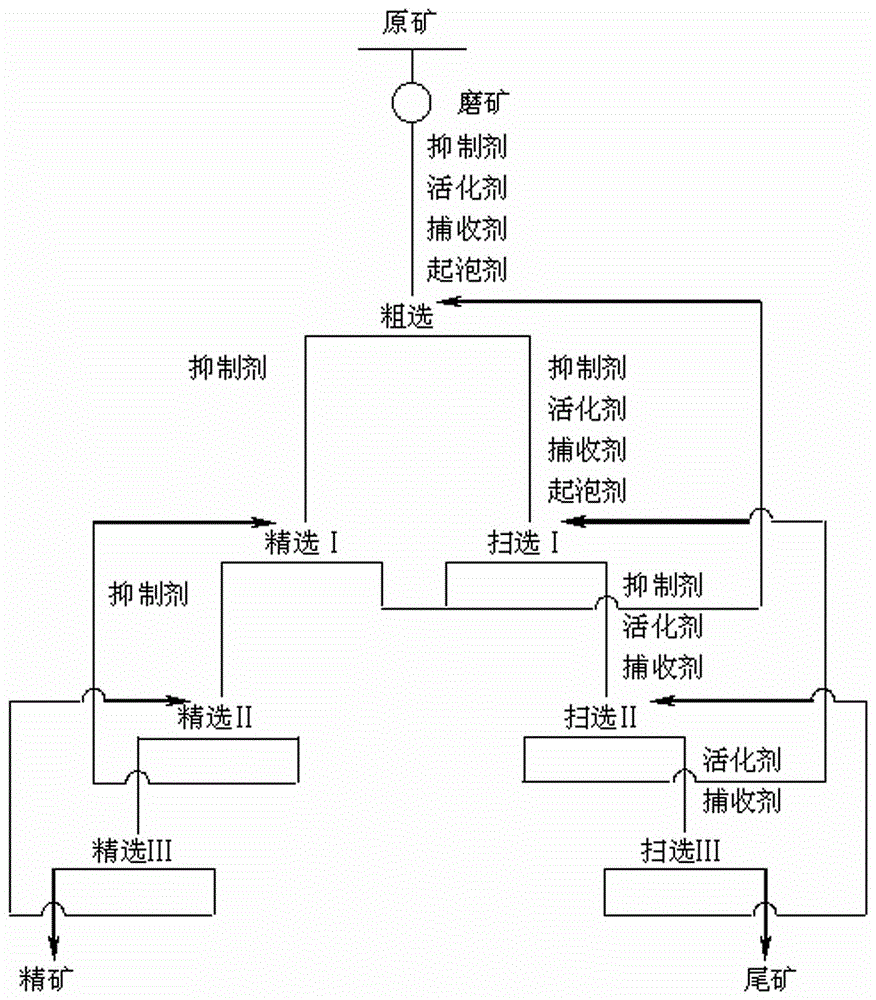

Method used

Image

Examples

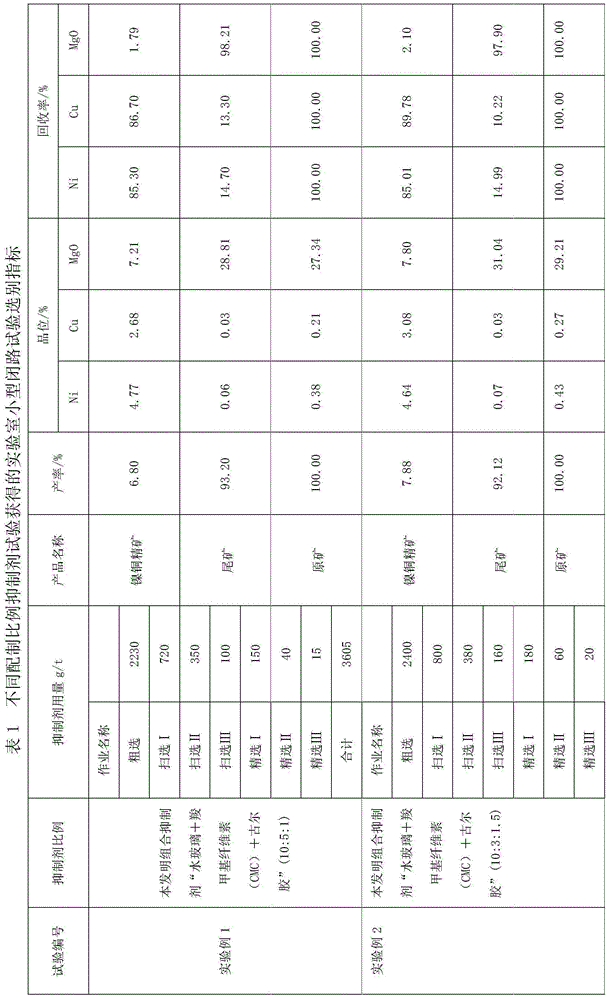

Embodiment 1

[0028] The ratio is: water glass: carboxymethyl cellulose: gull gum=10:5:1 inhibitor preparation.

[0029] A. Weigh 50 g of water glass, 25 g of carboxymethyl cellulose (CMC), and 5 g of gull gum.

[0030] B. Weigh 1520g of water (water temperature ≥ 20°C).

[0031] C. Slowly and evenly add the weighed gull gum into the weighed water while stirring continuously to make it fully dissolve.

[0032] D. Slowly and evenly add the weighed carboxymethyl cellulose (CMC) into the guer gum solution that has been fully dissolved in step C, while stirring constantly to make it fully dissolve.

[0033] E. Slowly and evenly add the weighed water glass in the Gur gum, carboxymethyl cellulose (CMC) solution that has been fully dissolved in step D, while constantly stirring, so that water glass, carboxymethyl cellulose (CMC) , Gur gum is fully dissolved and mixed. The mass percent concentration of preparation is 5%.

Embodiment 2

[0035] The ratio is: water glass: carboxymethyl cellulose: gull gum=10:3:1.5 The preparation of the inhibitor.

[0036] A. Weigh 50 g of water glass, 15 g of carboxymethyl cellulose (CMC), and 7.5 g of gull gum.

[0037] B. Weigh 1377.5g of water (water temperature ≥ 20°C).

[0038] C. Slowly and evenly add the weighed gull gum into the weighed water while stirring continuously to make it fully dissolve.

[0039] D. Slowly and evenly add the weighed carboxymethyl cellulose (CMC) into the guer gum solution that has been fully dissolved in step C, while stirring constantly to make it fully dissolve.

[0040] E. Slowly and evenly add the weighed water glass in the Gur gum, carboxymethyl cellulose (CMC) solution that has been fully dissolved in step D, while constantly stirring, so that water glass, carboxymethyl cellulose (CMC) , Gur gum is fully dissolved and mixed. The mass percent concentration of preparation is 5%.

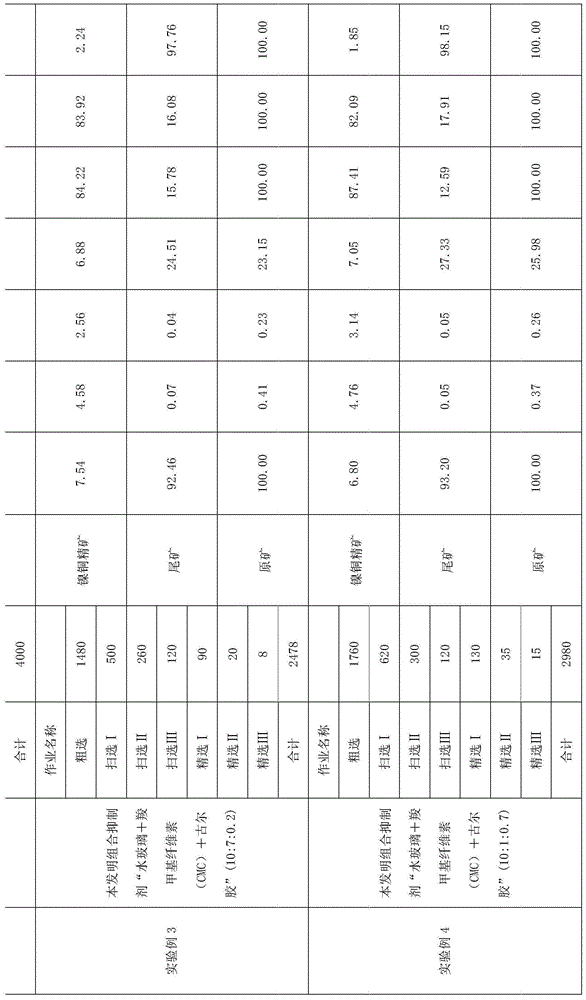

Embodiment 3

[0042] The ratio is: water glass: carboxymethyl cellulose (CMC): gull gum=10:7:0.2 The preparation of the inhibitor.

[0043] A. Weigh 50 g of water glass, 35 g of carboxymethyl cellulose (CMC), and 1 g of gull gum.

[0044] B. Weigh 1634g of water (water temperature ≥ 20°C).

[0045] C. Slowly and evenly add the weighed gull gum into the weighed water while stirring continuously to make it fully dissolve.

[0046] D. Slowly and evenly add the weighed carboxymethyl cellulose (CMC) into the guer gum solution that has been fully dissolved in step C, while stirring constantly to make it fully dissolve.

[0047] E. Slowly and evenly add the weighed water glass in the Gur gum, carboxymethyl cellulose (CMC) solution that has been fully dissolved in step D, while constantly stirring, so that water glass, carboxymethyl cellulose (CMC) , Gur gum is fully dissolved and mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com