Flotation separation method of talcum and copper pyrite

A separation method, chalcopyrite technology, applied in flotation, solid separation, etc., can solve the problems of talc fragility and mud, deterioration of flotation environment, foam stickiness, etc., to improve mineral processing index, improve grade and recovery rate, the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A large-scale copper-zinc-tin polymetallic paragenetic ore produced in magnesium skarn in China has a copper grade of about 0.133%. For pyrite, hornblende, pyroxene, quartz, potassium feldspar, talc, calcite, dolomite, fluorite, zoisite, epidote, garnet and titanite.

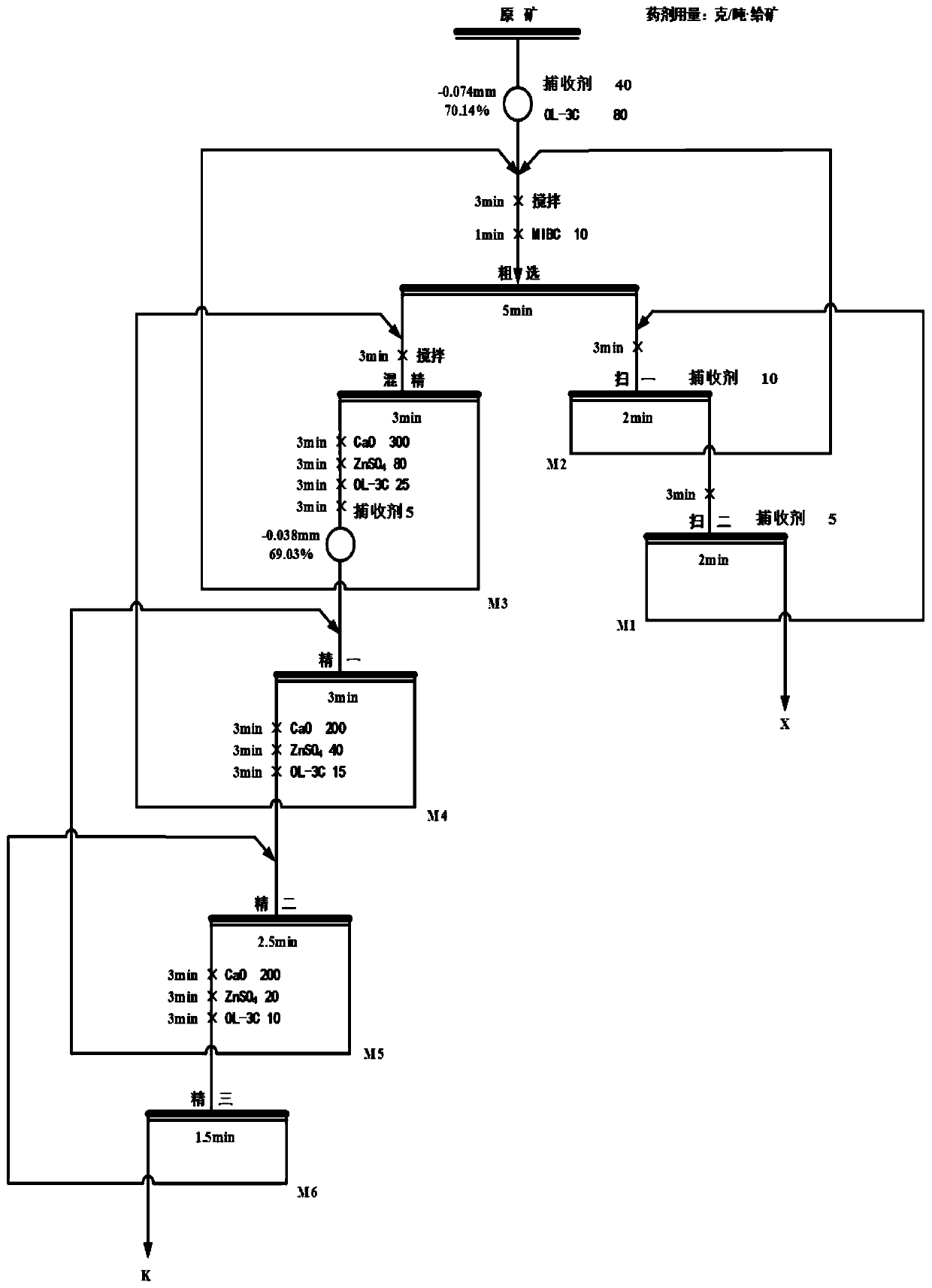

[0038] For the process mineralogy characteristics of this ore, adopt the flotation separation method of talc of the present invention and chalcopyrite, comprise the following steps:

[0039] (1) Add combined inhibitor OL-3C 80g / t to raw ore, add ammonium sulfate ester collector OL-ⅡA 40g / t, grind to -0.074mm, accounting for 70.14%;

[0040] (2) Add foaming agent MIBC 10g / t to the raw ore of predetermined fineness, and carry out roughing operation to obtain roughing concentrate and roughing tailings;

[0041] (3) Add ammonium sulfate ester collector OL-ⅡA to the roughing tailings, and obtain tailings X after secondary screening;

[0042] (4) Carry out blank concentration to the roughing concentrate to ob...

Embodiment 2

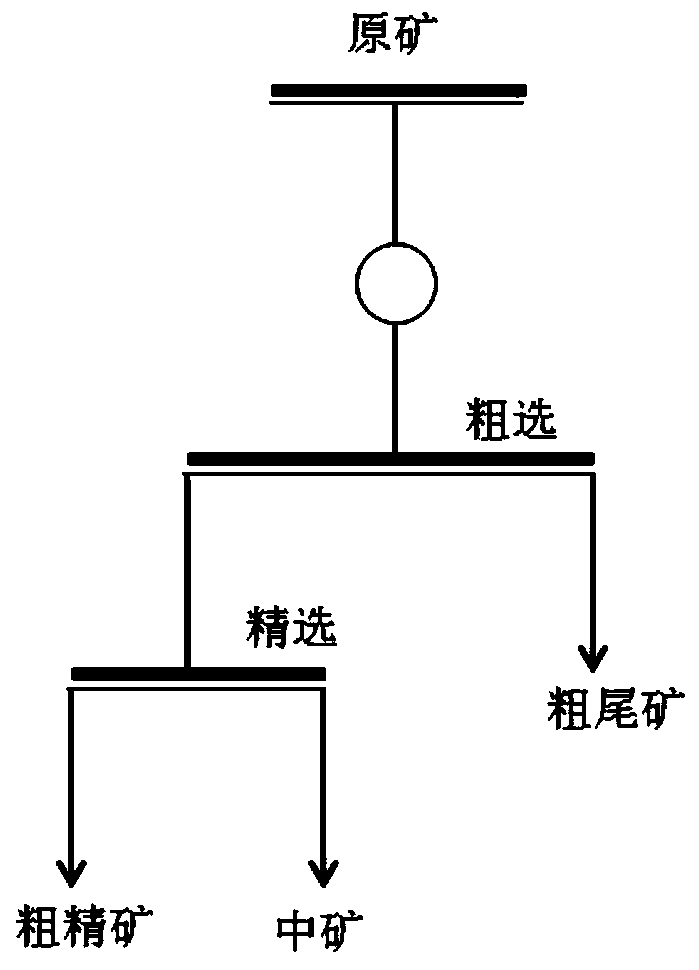

[0052] In order to verify the inhibitory effect difference between the combined inhibitor OL-3C of the present invention and the existing inhibitors, the ore feeding properties are the same as in Example 1, and the flow process adopted is: a section of grinding product undergoes a rough selection and a selection to obtain a rough Concentrate, medium ore, rough tailings, the specific process is as follows figure 2 shown;

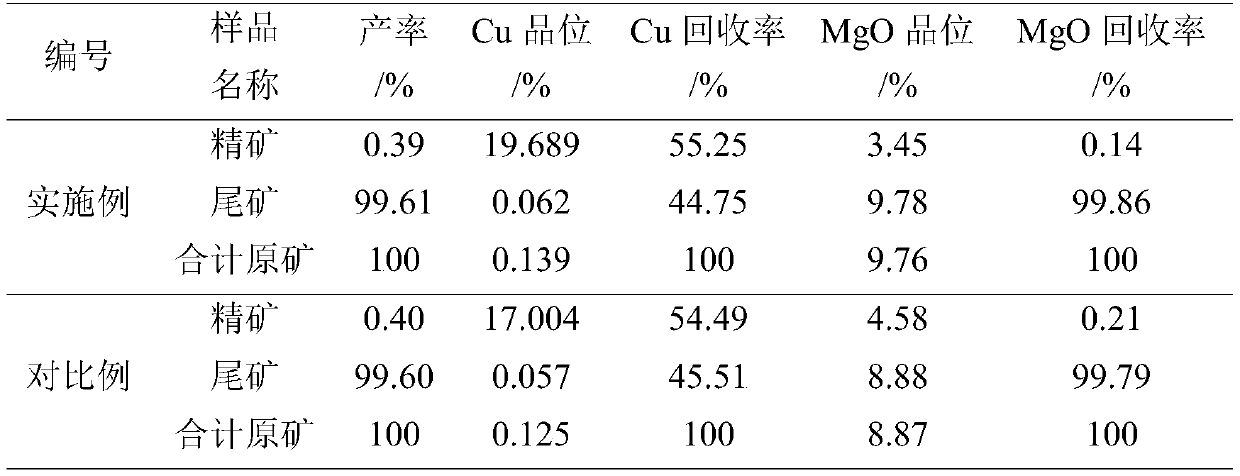

[0053] The beneficiation index of embodiment 2 is shown in Table 2:

[0054] The beneficiation index of table 2 embodiment 2

[0055]

[0056] As can be seen from Table 2, the combined inhibitor of carboxymethyl cellulose, CTP, and calcium lignosulfonate screened by the present invention has a good inhibitory effect on gangue, and has a good flotation effect on chalcopyrite at the same time As a result, the recovery rate of magnesium oxide is the lowest, and the grade and recovery rate of copper can reach a relatively ideal state.

Embodiment 3

[0058] Combination inhibitor OL-3C of the present invention has carried out component distribution ratio optimization test, technological process is identical with embodiment 2, and the beneficiation index of embodiment 3 is shown in Table 3:

[0059] The beneficiation index of table 3 embodiment 3

[0060]

[0061] As can be seen from Table 3, use the combined inhibitor (the 3rd group) within the proportioning range of the present invention, the grade and recovery rate of magnesia and copper can reach ideal state, but not within the proportioning range of the present invention Although the recovery rate of copper is relatively high for the combined regulator (group 1 and group 2), the grade of copper is very low and does not meet the requirements of ore dressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com