Twist bit for drilling mortar and for optimizing dissipation of heat and dust created by the drilling

a technology of drilling mortar and drilling hammer, which is applied in the direction of turning machine accessories, twist drills, manufacturing tools, etc., can solve the problems of not being suitable for the purposes, and achieve the effect of optimizing the dissipation of heat and dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

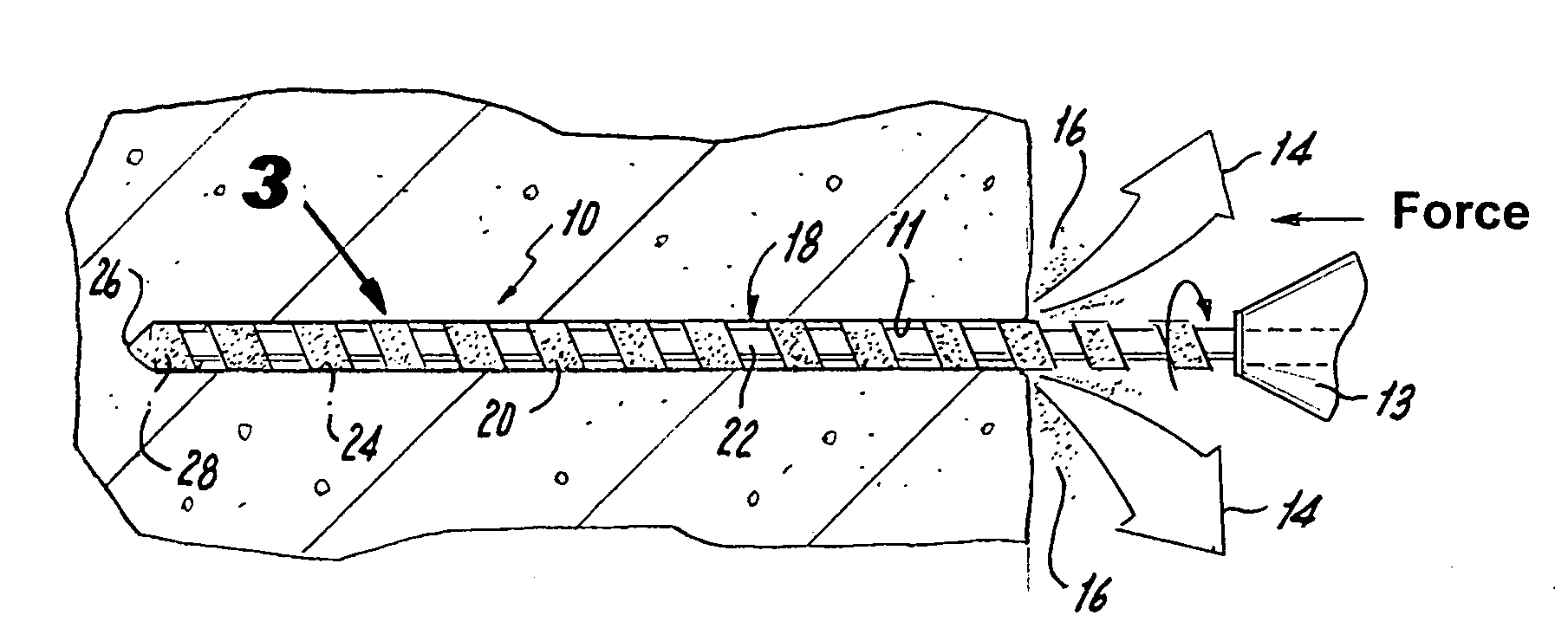

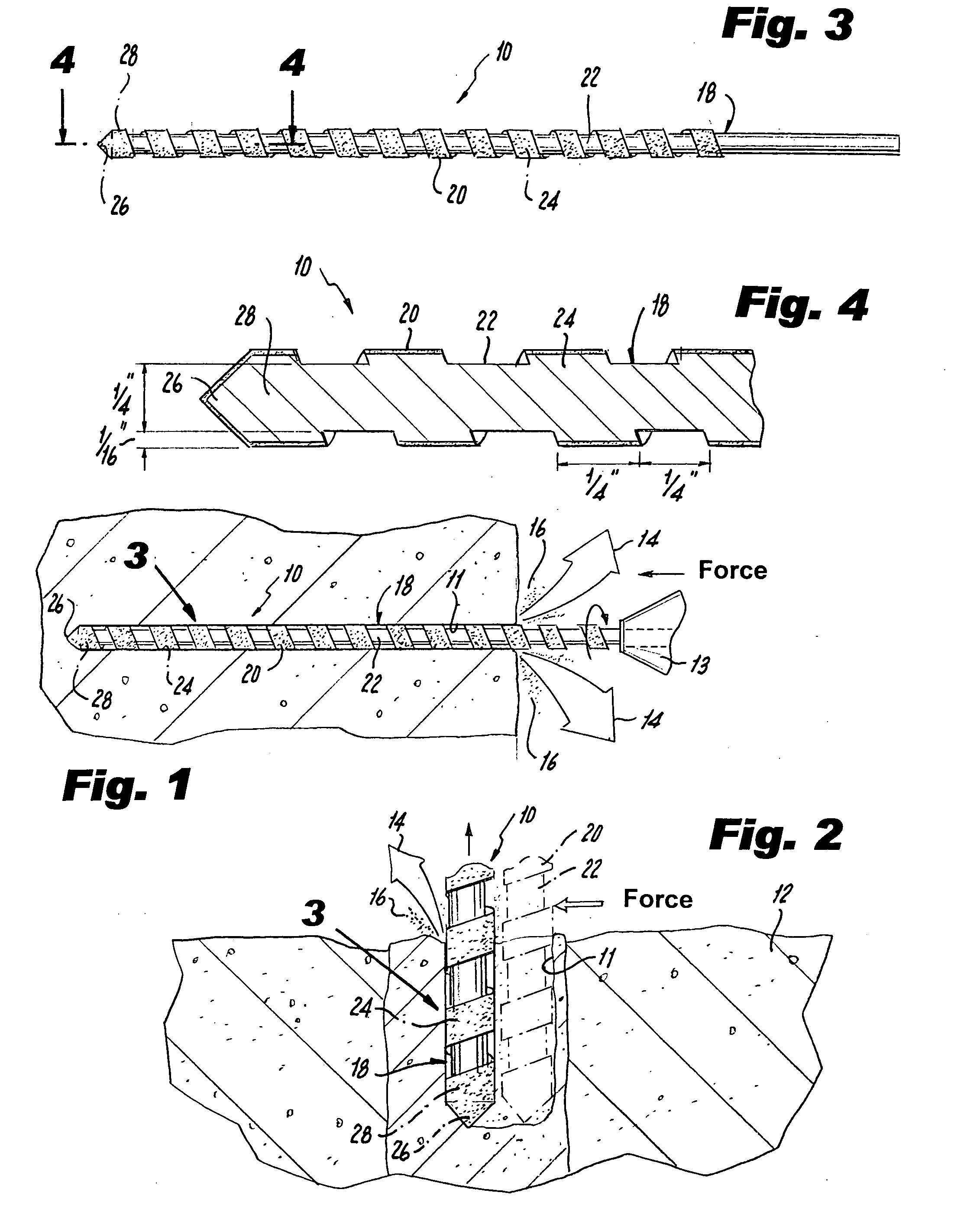

[0032] Referring now to the figures, in which like numerals indicate like parts, and particularly to FIGS. 1 and 2, which are, respectively, a diagrammatic cross sectional view through the mortar showing the twist bit of the present invention drilling an axial hole in the mortar and optimizing dissipation of heat and dust created by the drilling, and, a diagrammatic cross sectional view through the mortar showing the twist bit of the present invention drilling and cutting a lateral hole in the mortar and optimizing dissipation of heat and dust created by the drilling, the twist bit of the present invention is shown generally at 10 for drilling holes 11 in mortar 12 via a drill motor 13 and for optimizing dissipation of heat 14 and dust 16 from the hole 11 created by the drilling.

[0033] The configuration of the twist bit 10 can best be seen in FIGS. 3 and 4, which are, respectively, a diagrammatic side elevational view of the twist bit of the present invention identified by ARROW 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com