Twist drill

A twist drill and drill tip technology, which is applied in twist drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of material plasticization and achieve favorable pressure distribution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

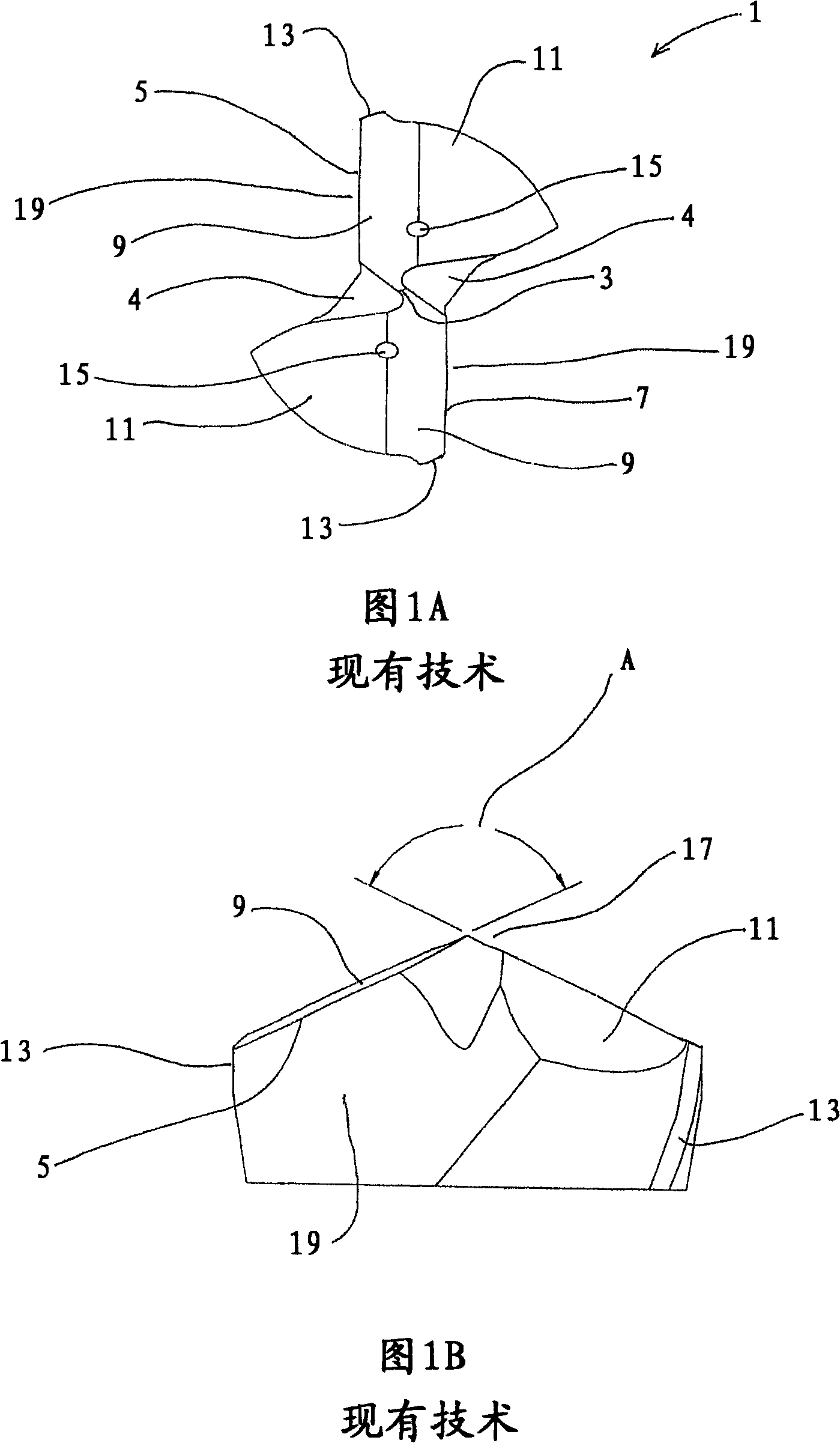

[0117] Figure 1 shows the cutting end of a conventional twist drill, such as the CDX twist drill manufactured by Dormer Tools (Sheffield) Ltd. This drill has been discussed above.

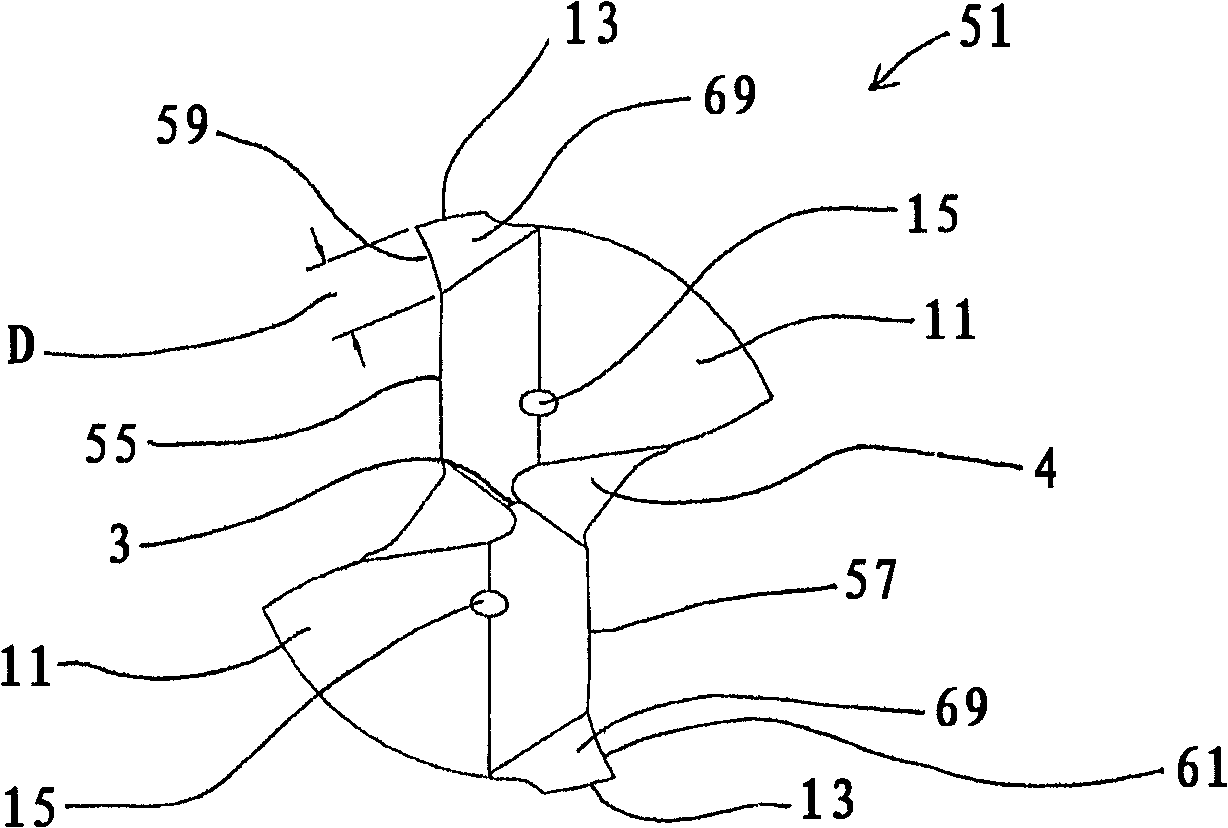

[0118] Figure 2A and 2B An embodiment of the invention is shown wherein the metalworking twist drill is made of cemented carbide. Other materials are also possible, such as HSS and the like.

[0119] The cutting bit 51 of the twist drill has many features in common with the conventional twist drill shown in Figures 1A and 1B, and the same reference numerals are used to denote common features.

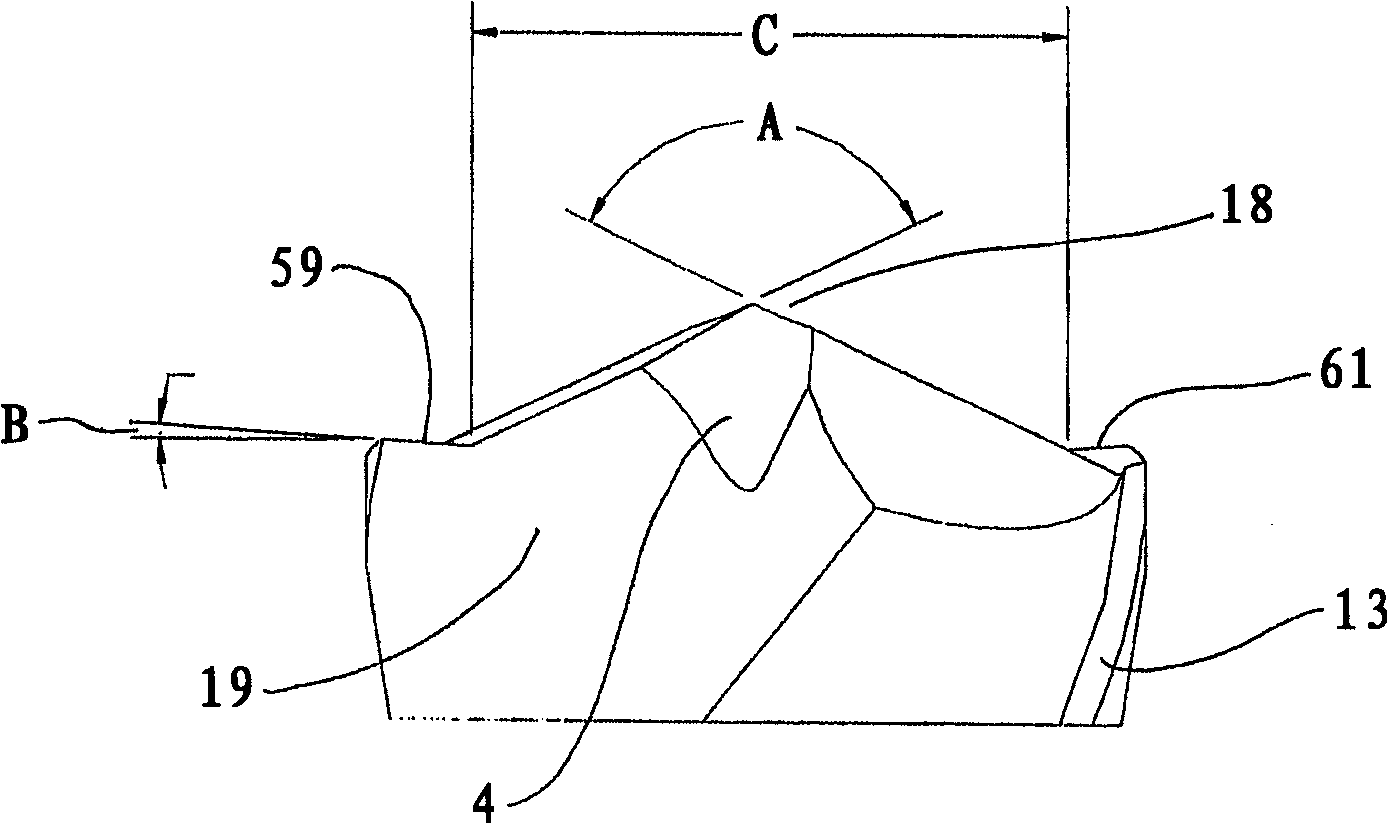

[0120] This embodiment differs from the conventional twist drill of Fig. 1 in that the cutting edges comprise inner cutting edges 55, 57 and outer cutting portions 59, 61 located radially outside these inner parts.

[0121] The inner cutting edge forms a drill point 18, which has a positive angle A, in this case 130°. Other point angles can also be used, preferably in the range of 115° to 155°.

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com