Two-flute twist drill

a twist drill and two-flute technology, applied in the field of twist drills, can solve the problems of high-specialized twist drills that only a professional machine shop can afford, high-specialized twist drills can be an unjustifiable expense, and high-specialized twist drills can be expensive in and of themselves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

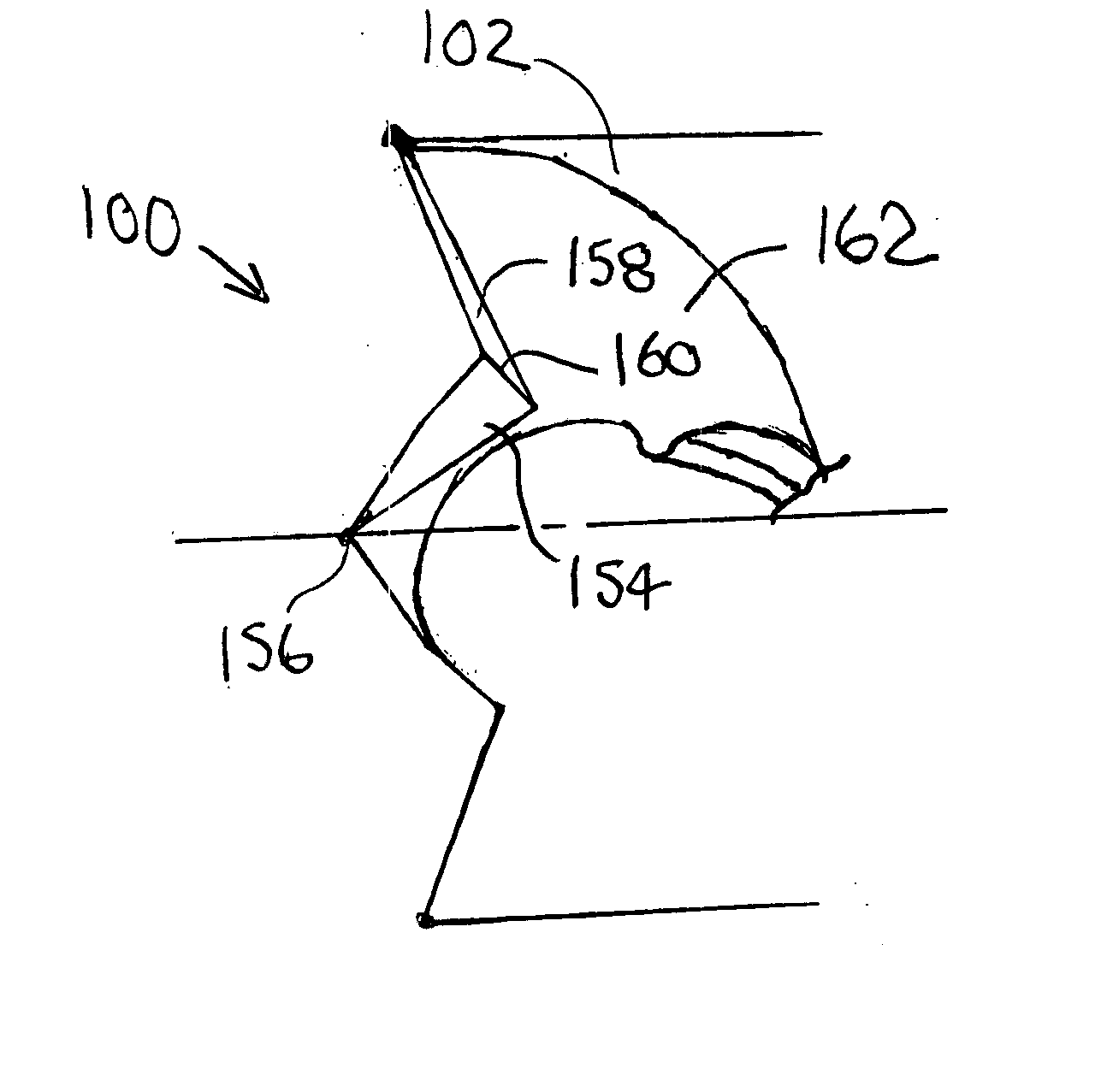

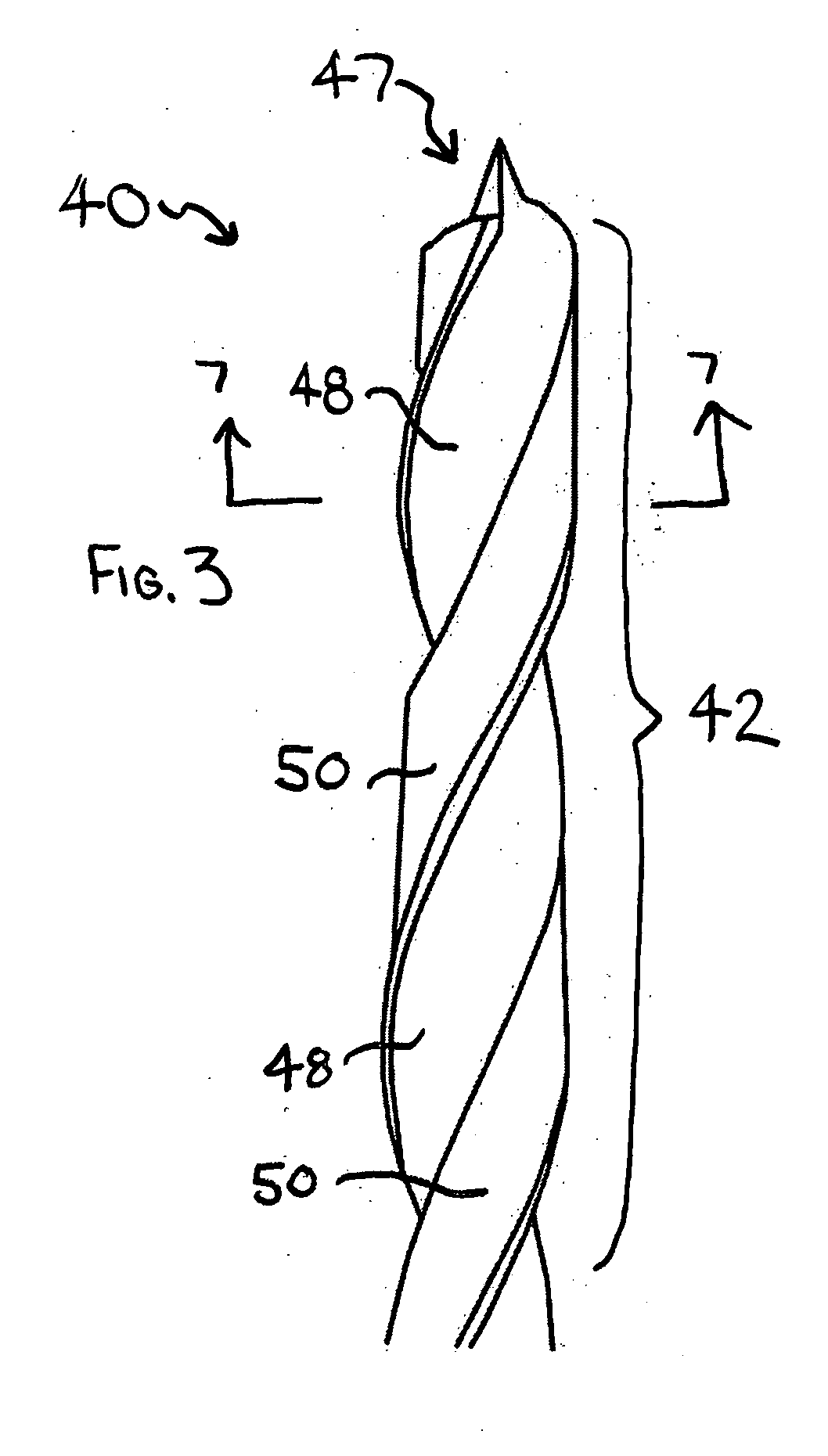

[0058] While this invention is susceptible of embodiment in many different forms, there is shown in the drawings and will be described in detail several specific embodiments, with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention and is not intended to limit the invention to the embodiments illustrated.

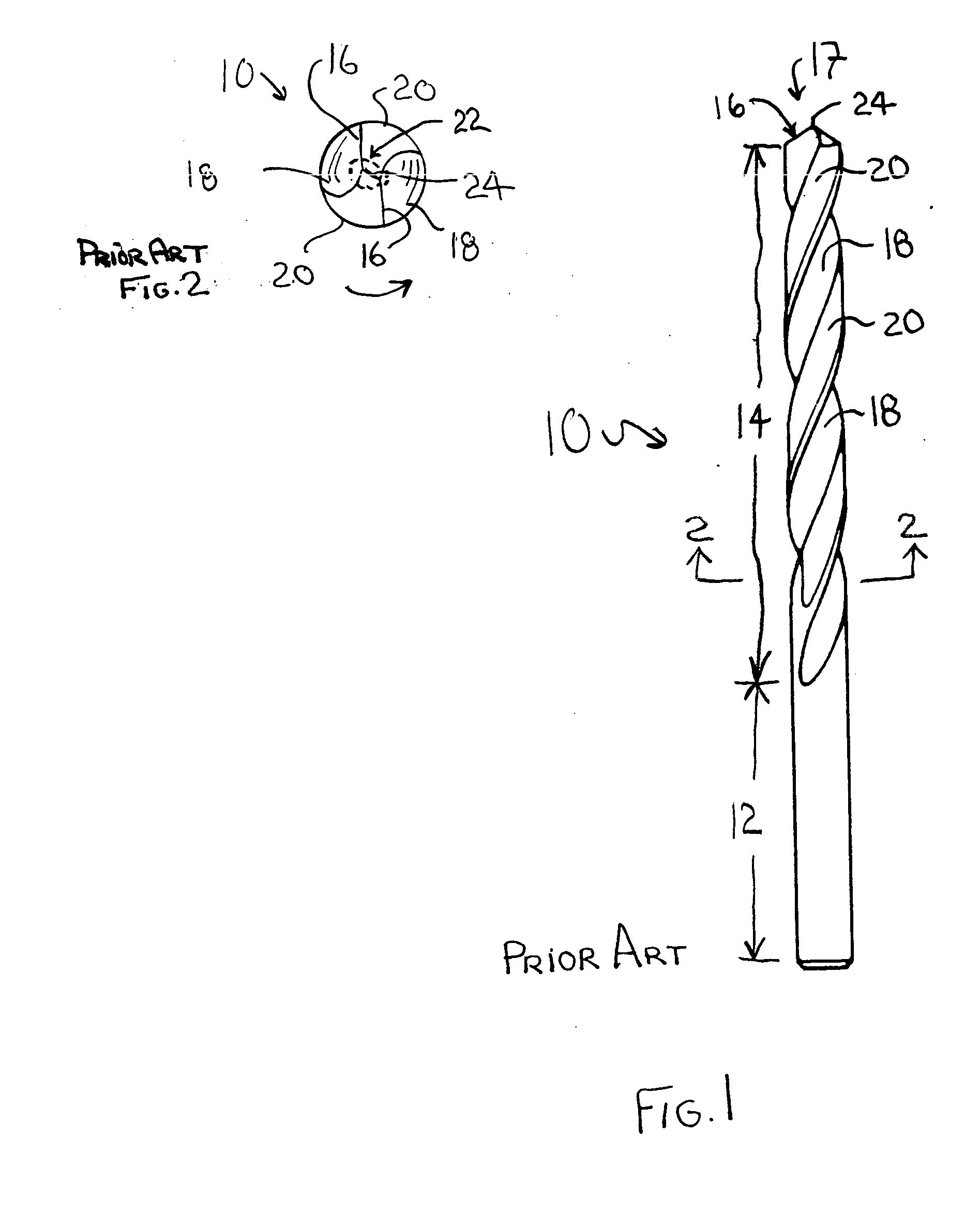

[0059]FIGS. 1-2 illustrate a prior art general purpose twist drill 10, which may be formed from any suitable material, such as M50 steel, although other materials may be used. Twist drill 10 is shown, not only to provide an illustration of a representative general purpose bit, but also to provide visual reference for certain terms to be used herein, with reference to the twist drill construction of the present invention. Twist drill 10 may be used typically on materials such as brass, bronze, as well as hard plastics, drywall, fiberboard and the like, and such bits are often used by non-professional do-it-yourselfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle α2 | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com