Twist drill

a twist drill and drill bit technology, applied in the field of twist drills, can solve the problems of large range of required drill lengths and drill diameters, large cost of twist drills, and large drilling diameters,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

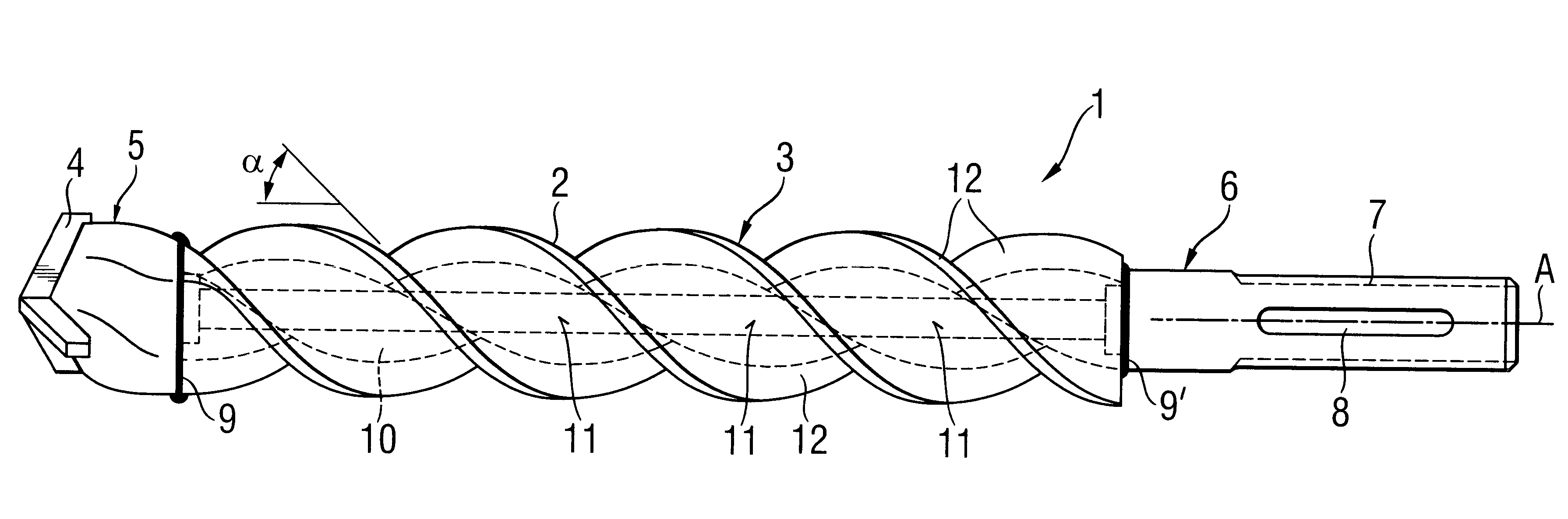

A twist drill 1 according to the present invention, which is shown in the drawings, includes a hollow shaft 3 which forms a spiral 2 and has an inner spiral-shaped surface, a drilling head 5 which is provided at one end of the shaft 3, and a shank 6 which is provided at another end of the shaft 3. The drilling head 5 is formed symmetrically with respect to its cutting bit 4 formed of a hard material. The shank 6 is provided with entraining grooves 7 and locking grooves 8 and is so formed that it appropriately engages in the shaft 3, formlockingly by interlocking of the materials of the shank 6 and the shaft, by circumferential connection seams 9 and 9'. The three-start spiral 2 is formed as a steep spiral and with a start angle .alpha. of 50.degree.. The hollow shaft 3 is filled with a viscoelastic, hollowed, as a result of being centrifuged, material 10.

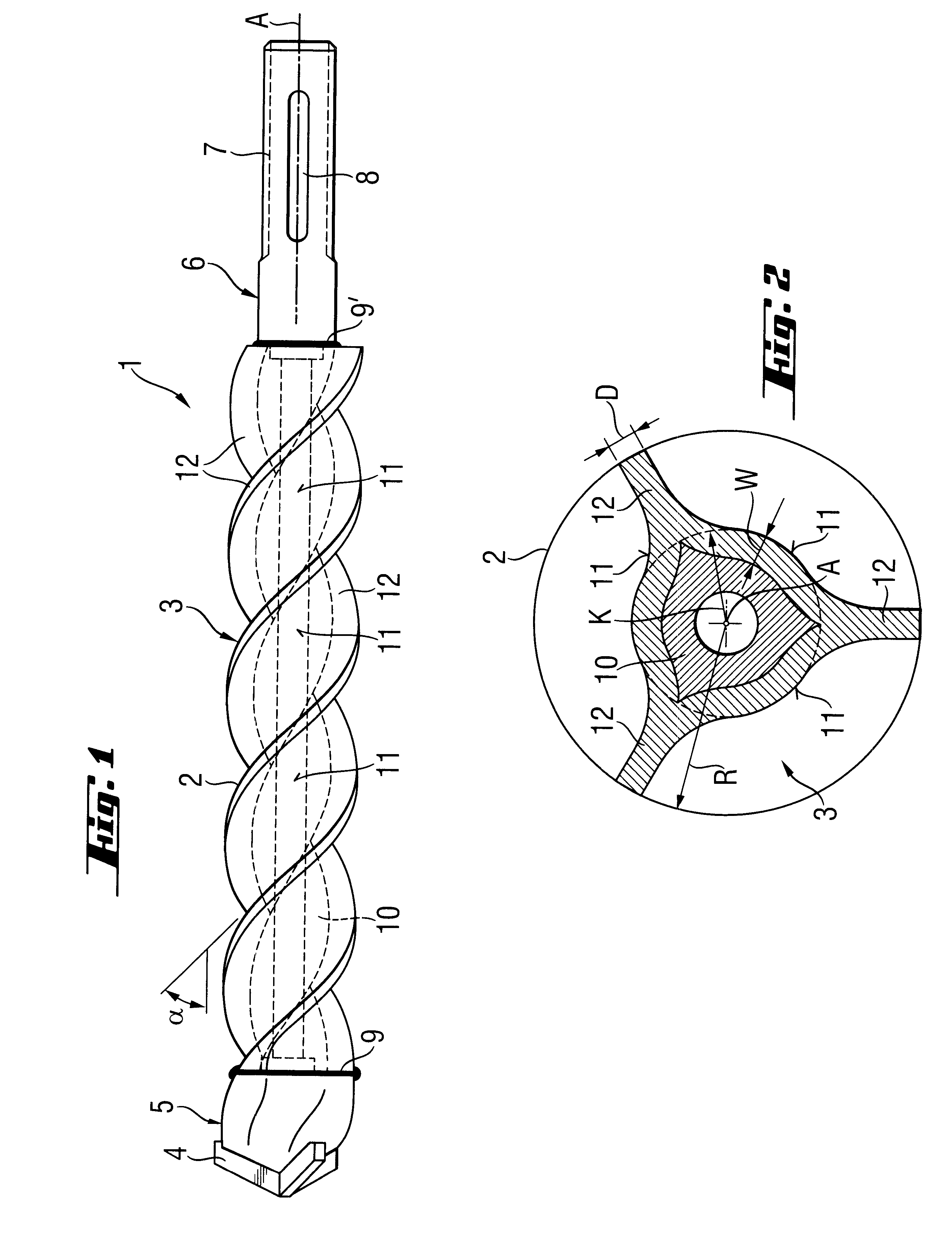

As shown in FIG. 2, the outer cross-sectional profile of the spiral 2 has a trigonal symmetry with respect to the drill axis A. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| start angle | aaaaa | aaaaa |

| start angle | aaaaa | aaaaa |

| hard | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com