Compound positioning and cutting spiral cutter

A composite positioning and cutting tool technology, which is used in drilling tool accessories, manufacturing tools, components of boring machines/drilling machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

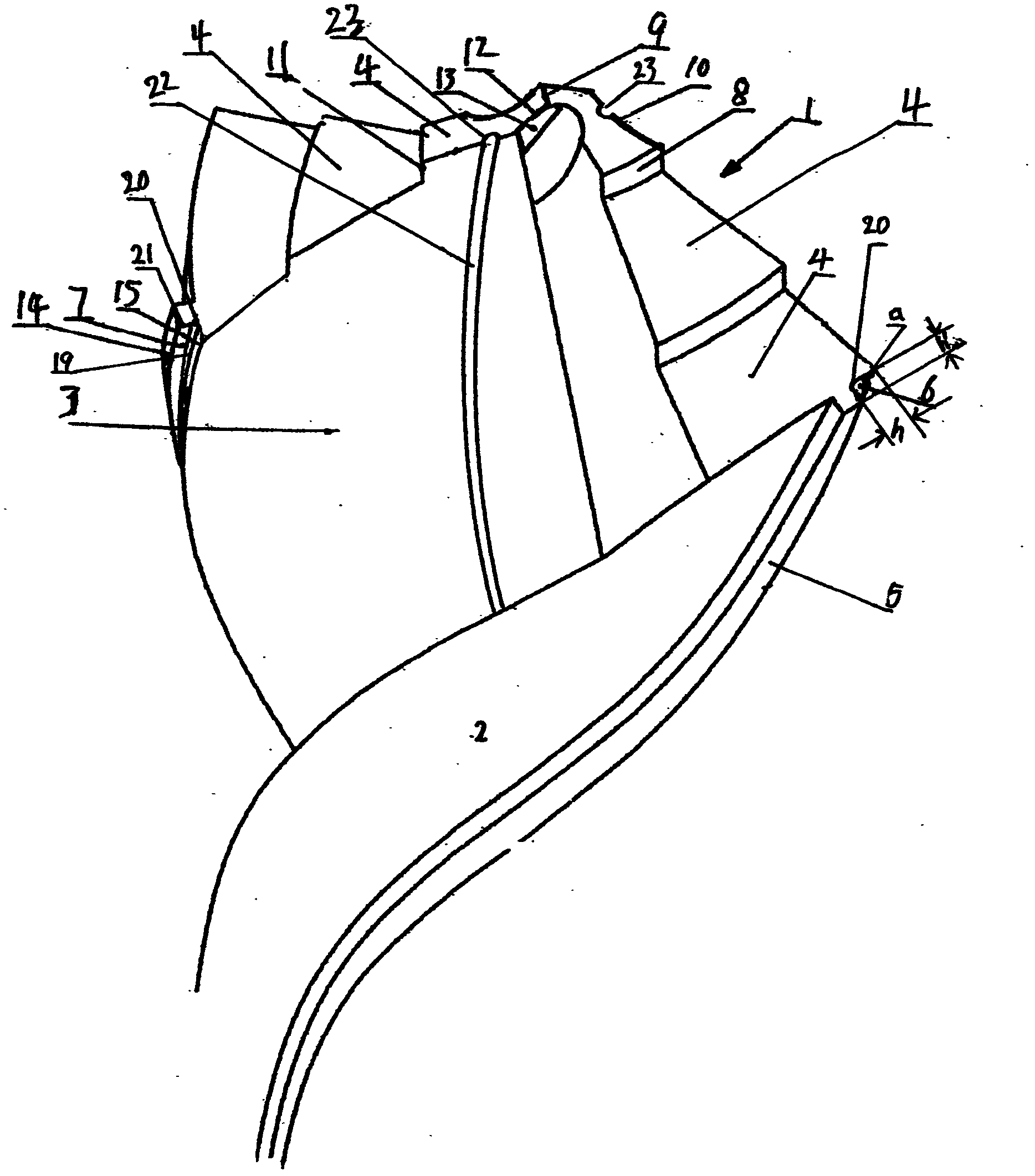

[0041] Such as figure 1 As shown, the helical tool for compound positioning cutting according to the first embodiment of the present invention mainly relates to a machined twist drill for mechanical processing, including a tool head, which is integrally provided with a plurality of helical strips 2, and each helical strip The edge facing the outer side of the cutting direction is formed as a helical minor cutting edge 14, the surface facing the rotation direction where the helical minor cutting edge 14 is located is formed as a helical cutting surface 7, and the surface of the axial front end back side of the helical cutting surface 7 is formed as a rear surface. The cutting surface 4, the helical cutting surface 7 and the rear cutting surface 4 intersect to form a cutting edge 21. On the helical tool for compound positioning cutting, the following technical solutions are integrated, or connected and formed as an integral body. In the helical pair The inner side of the helical...

Embodiment approach 2

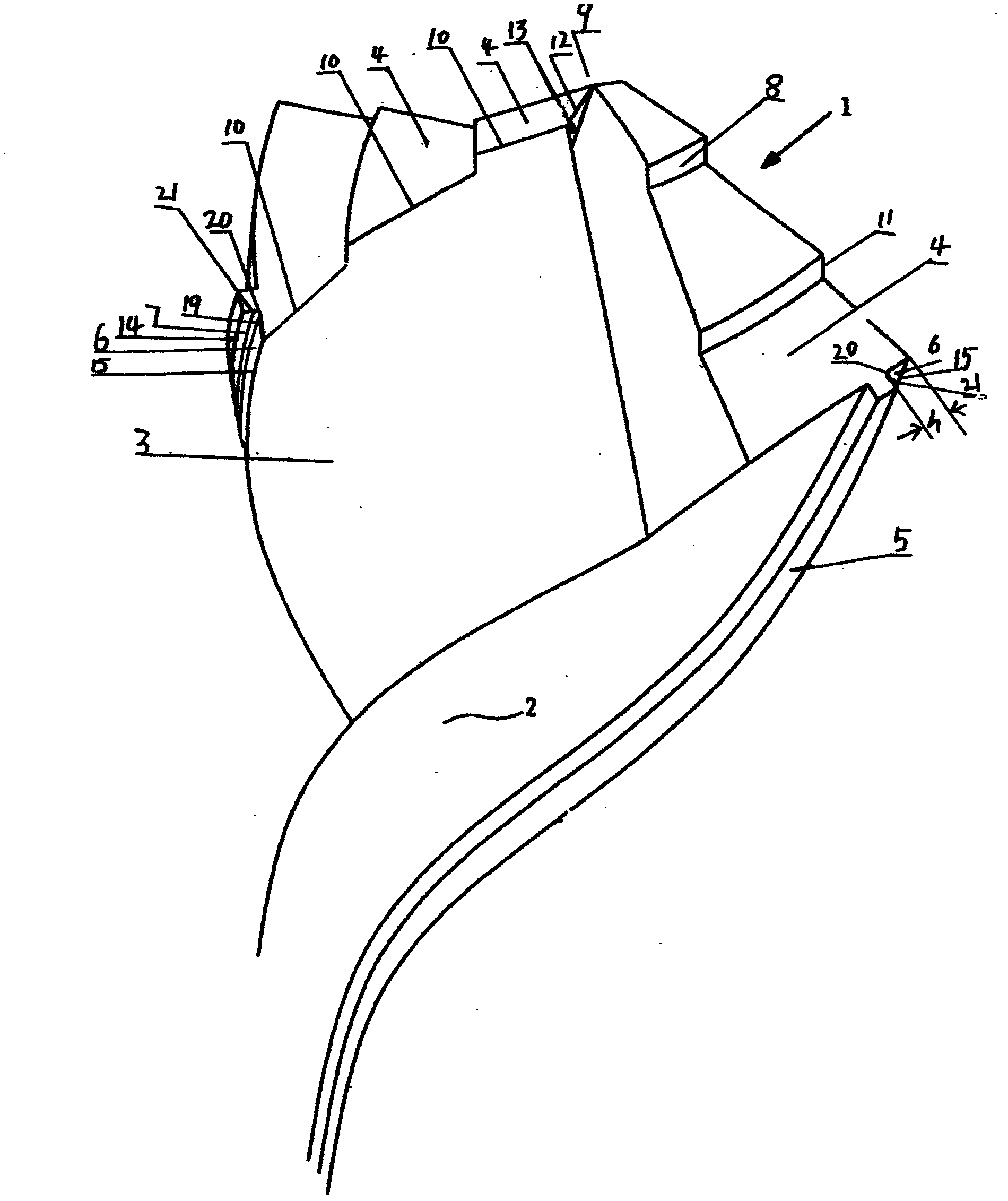

[0044] Such as figure 2 As shown, the helical tool for compound positioning cutting of the second embodiment of the present invention, on the basis of the first embodiment, this embodiment includes a cutter head 1, and the cutter head 1 is integrally provided with two helical strips 2, and the helical strips The surface facing the cutting direction of 2 is the helical cutting surface 3, the top back side of the helical cutting surface 3 is the rear cutting surface 4, the outermost surface of the spiral bar 2 is the helical helical secondary cutting surface 5, the helical cutting surface and the helical secondary cutting surface Surface 5 intersects to form a minor cutting edge 14, and the helical minor cutting surface intersects with the rear cutting surface to form a side edge. The auxiliary cutting surface is the composite positioning and decomposing platform 6, and the helical cutting surface 3 with at least one level of protrusion is the composite helical positioning cutt...

Embodiment approach 3

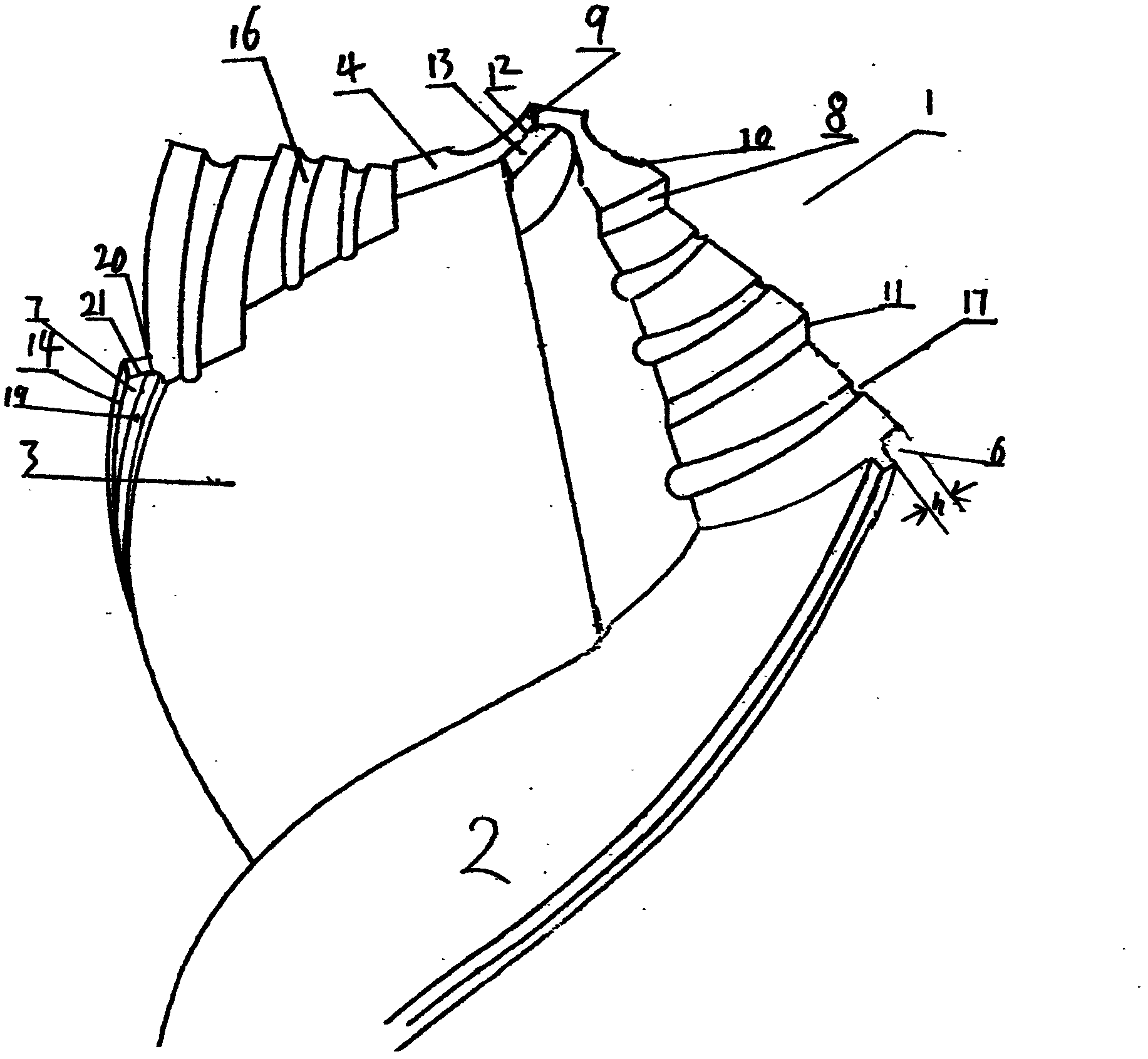

[0047] Such as image 3 As shown, the helical tool for compound positioning cutting according to the third embodiment of the present invention is based on the first - second embodiments, and at least one notch edge 17 is provided on the stepped compound positioning cutting edge 10, which is The opening extends toward the rear cutting surface 4 with enlarged grooves 16, and on the rear cutting surface 4, a stepped portion 8 with a gradually decreasing height is formed on the rear cutting surface 4 from the chisel edge or sharp edge 9 to the two outer sides. A stepped edge 11 is formed on the cutting surface, and a centering cutting edge 12 extends downwards to form a chamfered surface 13 between the step portion 8 and the high-efficiency cutting table 10 .

[0048] According to the above-mentioned structure, the rear cutting surface 4 and the step portion 8 are protrudingly provided at the center top of the cutter head 1, so the cutter has good stability, and because the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com