Fully-automatic kitchen garbage separation equipment

A technology of food waste and separation equipment, applied in filtration separation, separation method, liquid separation, etc., can solve problems such as incomplete separation of solid residues, rough manufacturing process, ingenious design concepts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

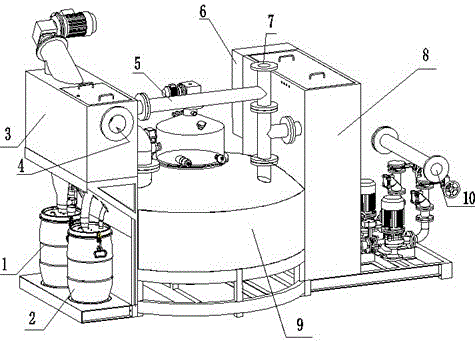

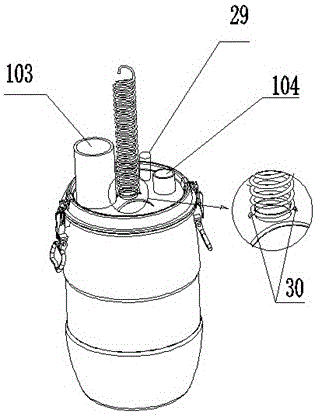

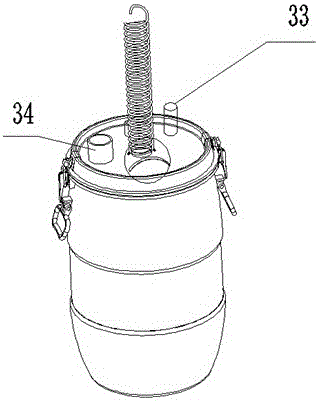

[0055] Such as Figure 1-Figure 20 Shown:

[0056] Fully automatic food waste separation equipment, equipped with a primary separation module 3, the primary separation module 3 is installed on the support frame 32, and the support frame 32 is provided with two barrel grooves, respectively placed the slag barrel 1 and the oil barrel 2, and the primary separation module 3 It includes a primary sedimentation bin 19 and a solid-liquid separation mechanism 18. The solid-liquid separation mechanism 18 is installed in the primary sedimentation bin 19. The solid-liquid separation mechanism 18 includes a power unit 16, a screw 27, a screw 28, a filter basket 26, and a material barrel. 25. The power unit 16 is connected to the screw rod 27 through the shaft, and the screw rod 27 is equipped with a screw piece 28. A slag outlet 78 is opened on the oblique upper side of the material barrel 25. The slag outlet 78 is connected to the slag barrel through the slag connecting pipe 101. The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com