Three-dimensional modeling apparatus, object, and method of manufacturing an object

A three-dimensional modeling and equipment technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problem that the lamination accuracy depends on the surface accuracy of the liquid surface, and achieve the effect of improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0069] (Structure of 3D modeling equipment)

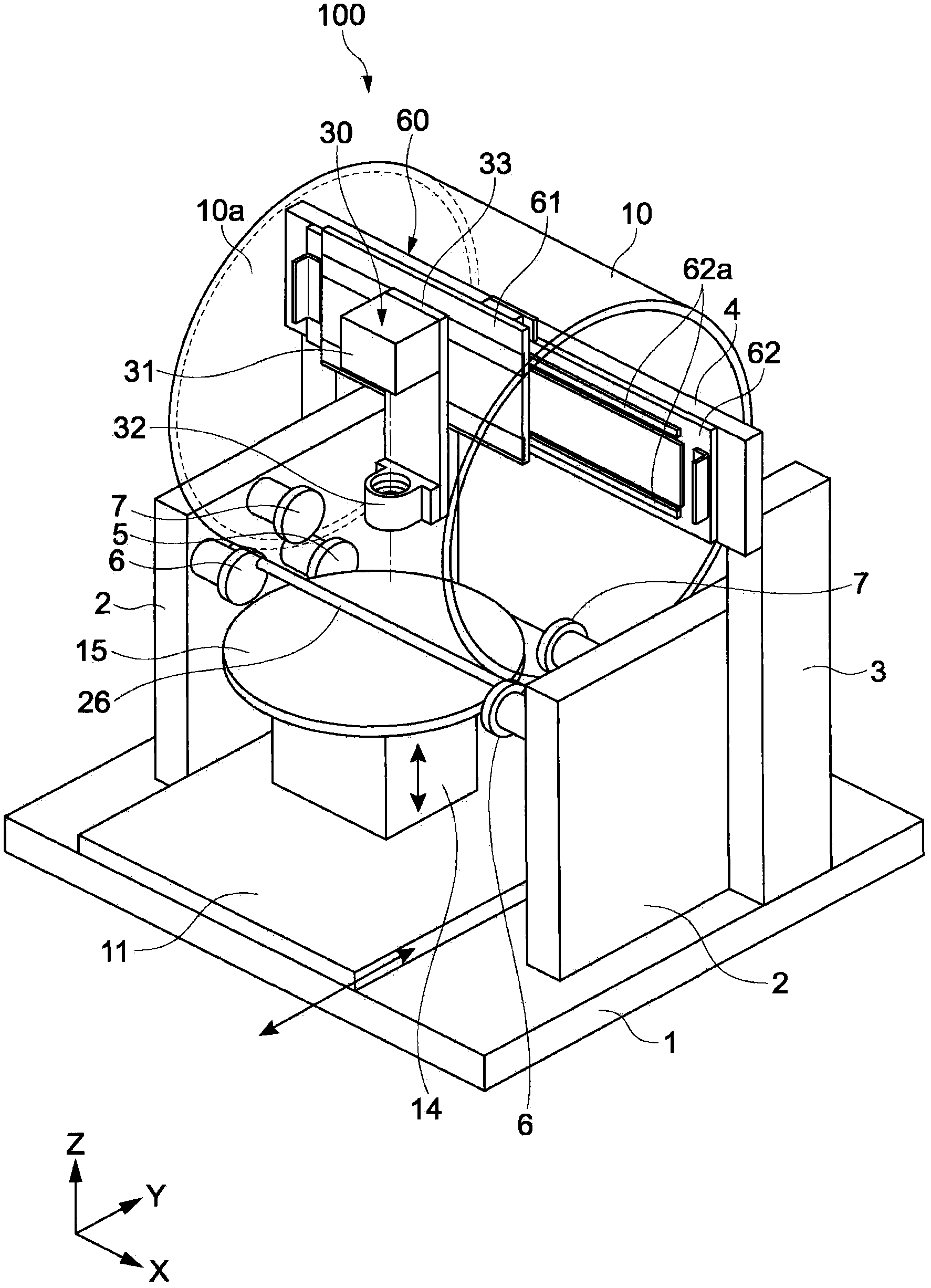

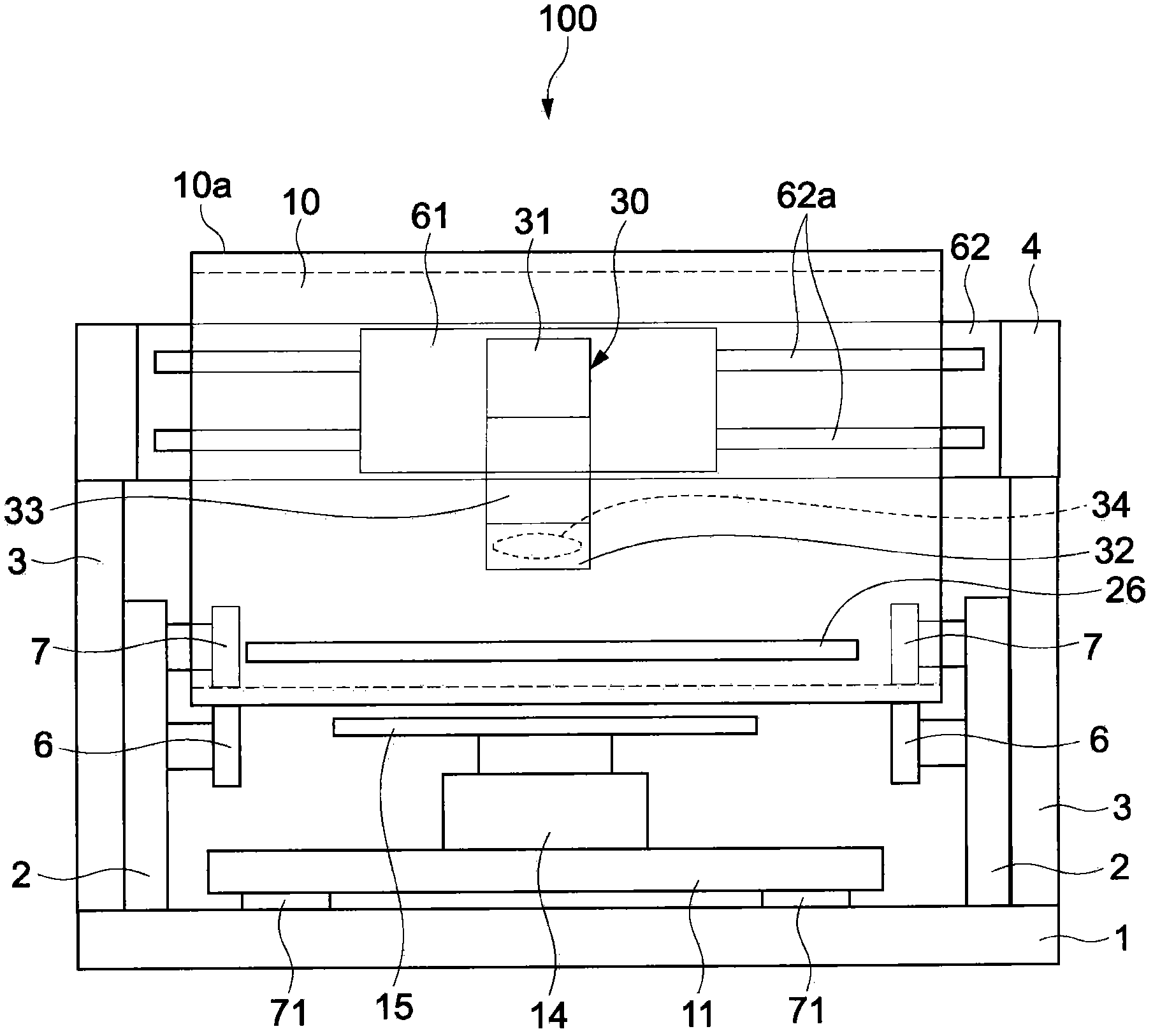

[0070] figure 1 is a perspective view showing a three-dimensional modeling apparatus according to a first embodiment of the present invention. figure 2 is the front view of the three-dimensional modeling equipment viewed along the Y-axis direction.

[0071] The three-dimensional modeling device 100 includes a base body 1 , two side walls 2 , a modeling platform 15 and a drum 10 . The side wall 2 is arranged vertically on the rear side on the base body 1 . A modeling stage 15 is arranged between the side walls 2 . The drum 10 functions as a restraining body, which is arranged opposite to the modeling stage 15 .

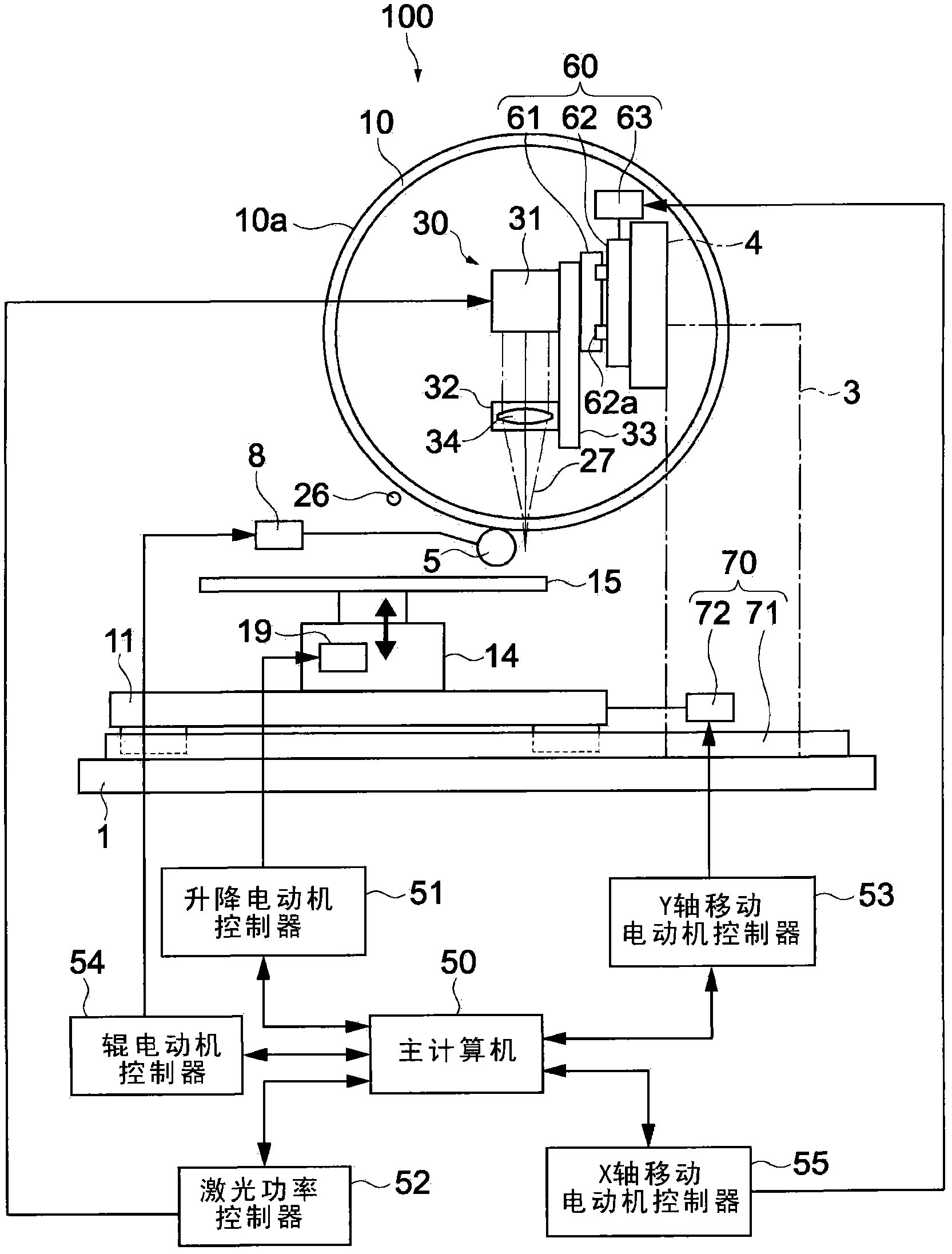

[0072] image 3 is a schematic side view showing the three-dimensional modeling apparatus 100, and a block diagram showing the configuration of a control system therefor.

[0073] As described below, the drum 10 functioning as a restraining body restrains the height of the top surface of the material supplied from t...

no. 2 example

[0129] Figure 9 is a side view showing main parts of a three-dimensional modeling apparatus according to a second embodiment of the present invention. Below, the comparison and basis will be simplified or omitted figure 1 In the description of the similar components and functions included in the three-dimensional modeling apparatus 100 of the embodiment shown in ect., differences will be mainly described.

[0130] Instead of the above-mentioned drums acting as restraints, Figure 9 The illustrated three-dimensional modeling apparatus 200 includes a plate member 20 having a surface formed into a curved surface. The plate member 20 is generally part of a cylinder. The plate member 20 includes a lower surface 20a and an upper surface 20b. The lower surface 20a is opposed to the modeling stage 15, and is supported by a plurality of guide rollers 45 and 46, for example. The upper surface 20 b is held by guide rollers 47 . An irradiation unit 30 is arranged on the side of th...

no. 3 example

[0136] Figure 10A and Figure 10B They are respectively a side view and a front view of the three-dimensional modeling device according to the third embodiment of the present invention.

[0137] The constrained body of the three-dimensional modeling apparatus 210 according to the present embodiment is a semi-cylindrical body 40 corresponding to a part of the cylindrical body. In other words, each of the semi-cylindrical body 40 and the plate member 20 according to the second embodiment corresponds to a part of a cylindrical body, and has the same function and effect except that the curvature of its outer peripheral surface is different.

[0138] The irradiation unit 80 of the three-dimensional modeling device 210 according to this embodiment includes a laser source 31 and a condenser lens 134 . The condensing lens 134 has a function of condensing laser light. Laser light from the irradiation unit 80 scans the resin liquid R in the X-axis direction through the galvanometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com