Vibrating screening and separation mechanism of copper crushing machine

A technology of vibrating screening and separating mechanism, applied in solid separation, screening, removing smoke and dust, etc., can solve the problems of time-consuming, labor-intensive, incomplete separation, and high labor intensity for recovering cables, and achieves convenient operation, compact structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

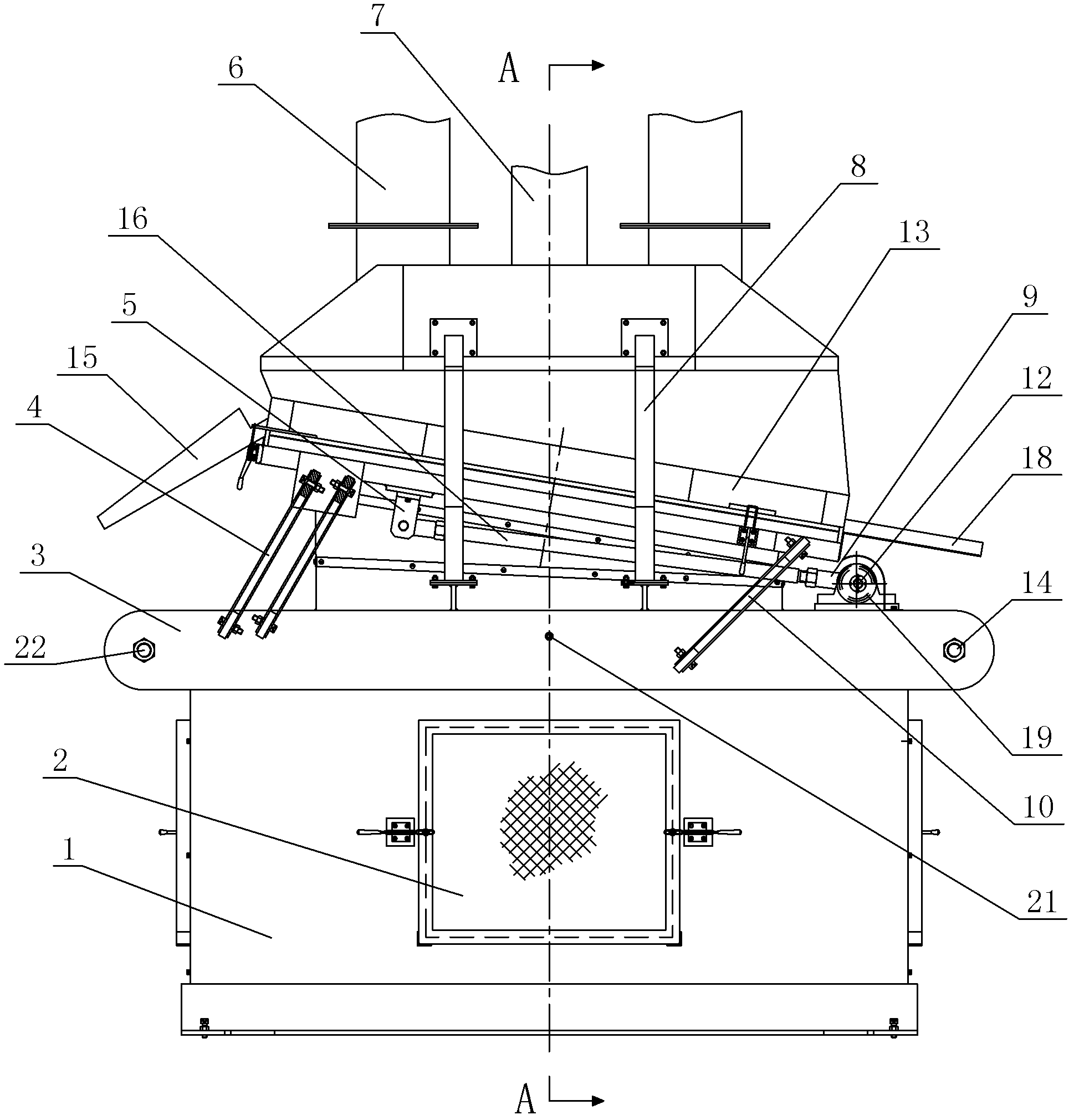

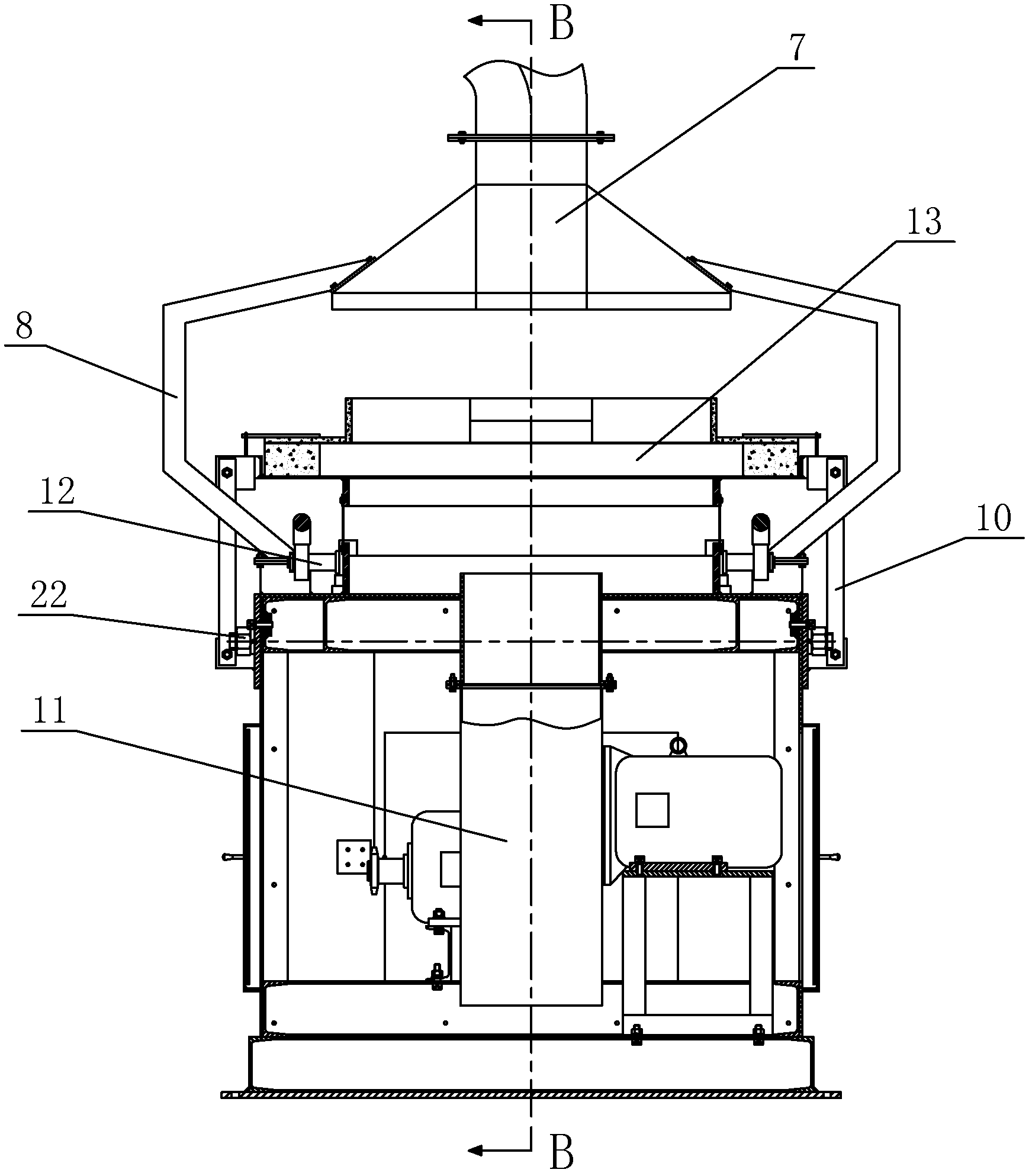

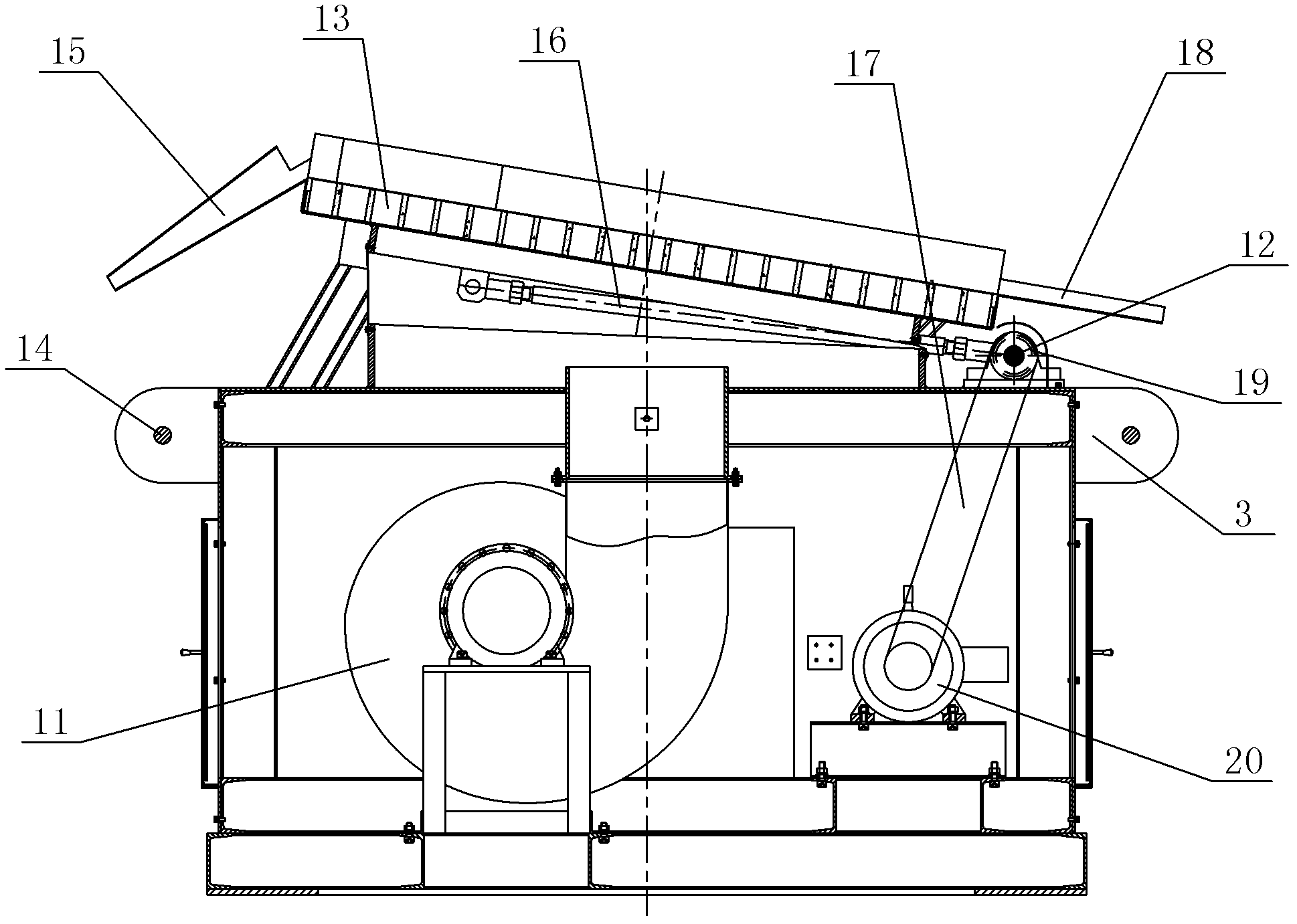

[0028] like figure 1 , figure 2 and image 3 As shown, the present invention includes a frame 1, an air inlet 2, an adjustment plate 3, a first spring plate 4, an air suction port 6, a feed port 7, a support frame 8, a second spring plate 10, a fan 11, an eccentric shaft 12, Screen 13, pull rod 14, first discharge port 15, connecting rod 16, chain 17, second discharge port 18 and motor 20, described air inlet 2 is arranged on the bottom of frame 1, and described blower fan 11 is installed on At the air inlet 2, the adjusting plate 3 and the pull rod 14 are installed in the middle of the frame 1, the screen 13 is arranged above the adjusting plate 3, and the first spring plate 4 and the second spring plate 10 are installed Between the adjustment plate 3 and the screen cloth 13, the first discharge port 15 and the second discharge port 18 are all arranged on the screen cloth 13; the eccentric shaft 12 is arranged on the adjustment plate 3, and the motor 20 Form a chain trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com