Special automatic charger for automatic guided vehicle

An automatic guided vehicle and automatic charging technology, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of large space occupation, increased use cost, and inability to work, so as to improve the utilization rate and reduce the Effect of replacement frequency and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

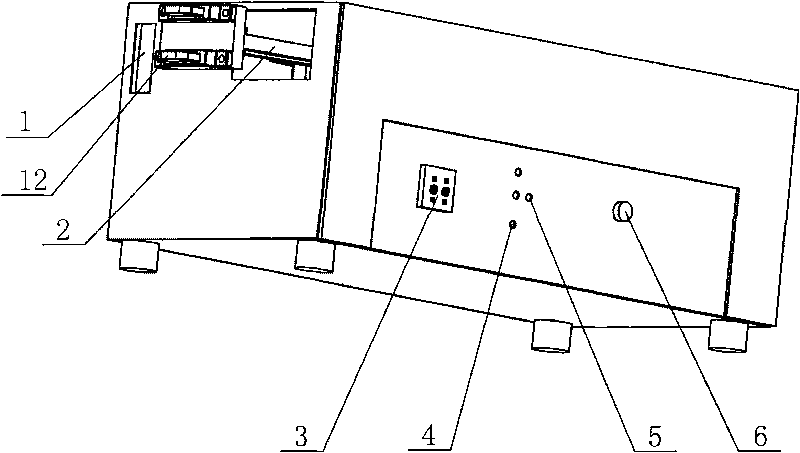

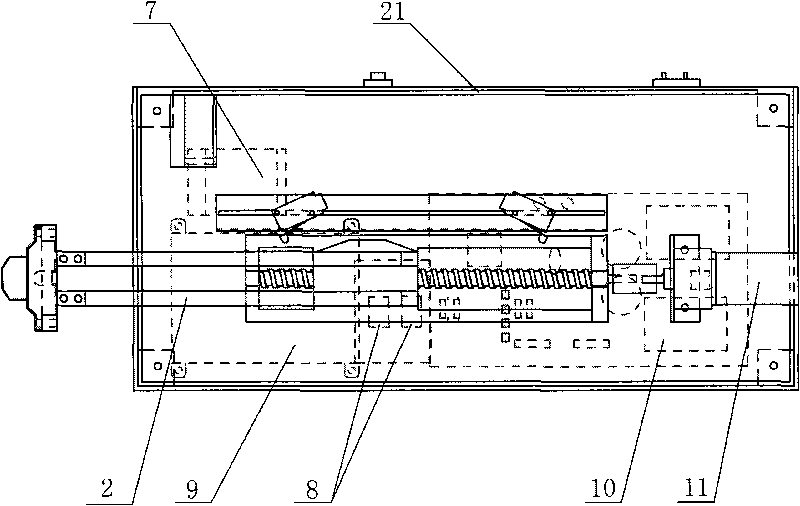

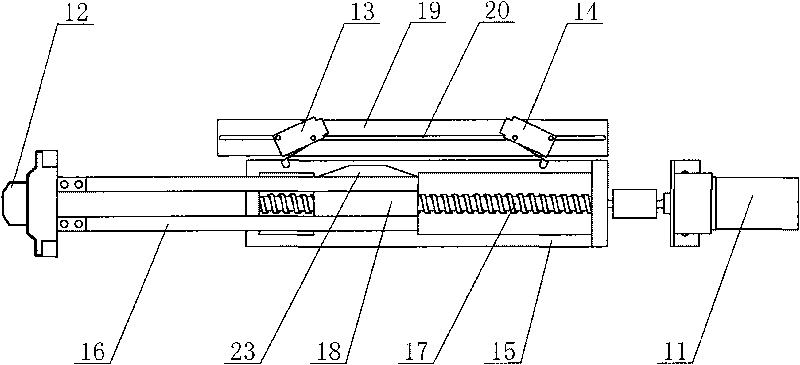

[0023] Embodiment one: see Figure 1 to Figure 5 As shown, a special automatic charger for an automatic guided vehicle includes a housing 21 and a charging unit 10 disposed in the housing 21, a control unit 9 and a connecting portion connected to the guided vehicle, the connecting portion includes a control switch assembly, The linear slide rail module 2 and the electronic collector 12 connector electrically connected to the charging interface of the guide vehicle, the linear slide rail module 2 includes a drive motor 11, a guide frame 15, a slide rail 16 and a screw rod 17 connected to the motor 11 , the screw rod 17 is installed in the guide frame 15, the slide rail 16 is screwed on the screw rod 17 through a connecting block, and has a degree of freedom to extend out of the housing along the extending direction of the guide frame 15 The control switch assembly includes an inductive element 1 disposed on the housing and front and rear limit switches that are in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com