Etching method and etching composition useful for the method

a technology of silicon nitride and composition, which is applied in the direction of surface treatment composition, decorative arts, chemistry apparatus and processes, etc., can solve the problems of difficult continuous use of such an etchant, no constant effect of its addition is available, and large damage to silicon oxide, etc., to achieve high selective etching efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

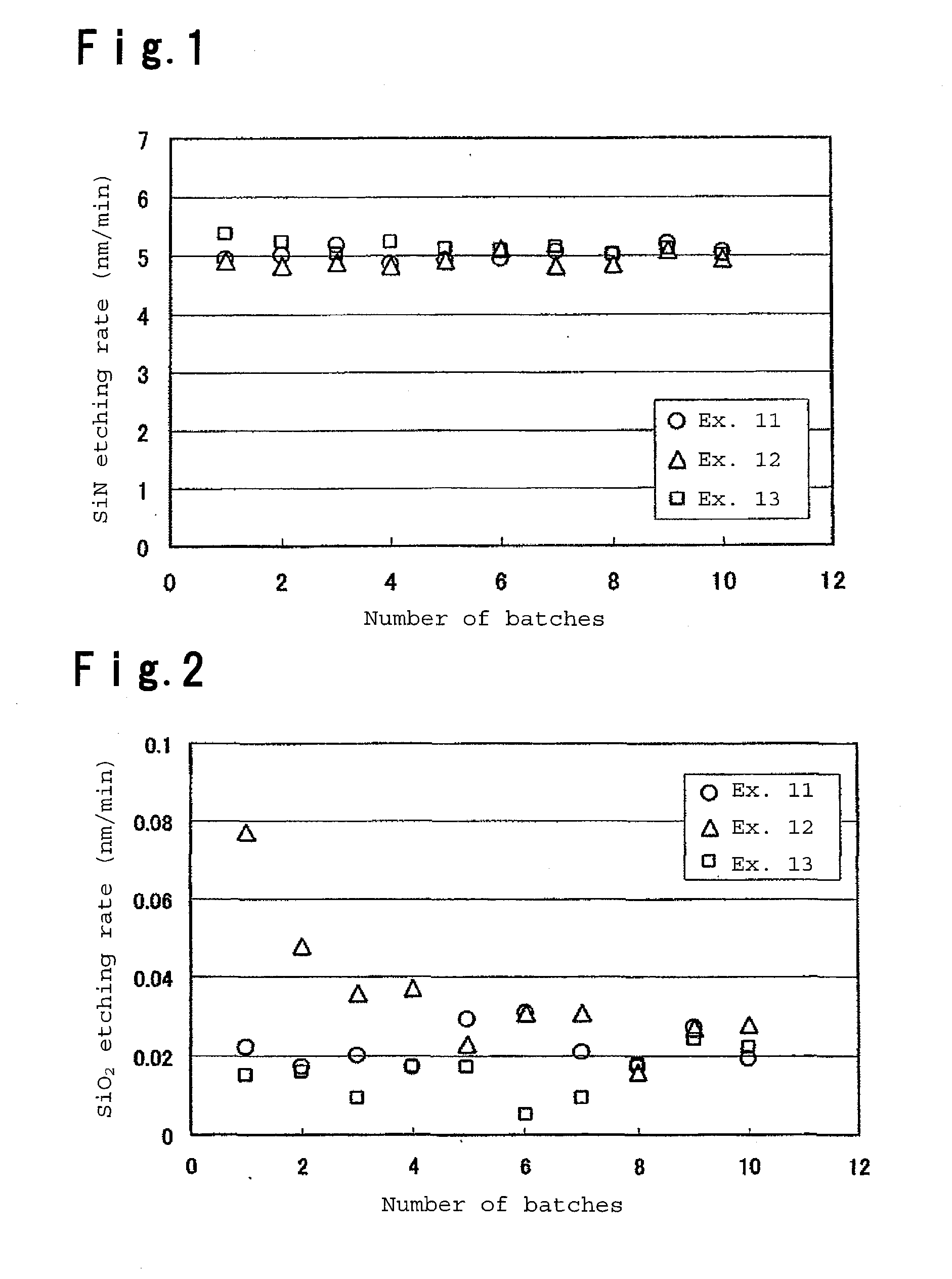

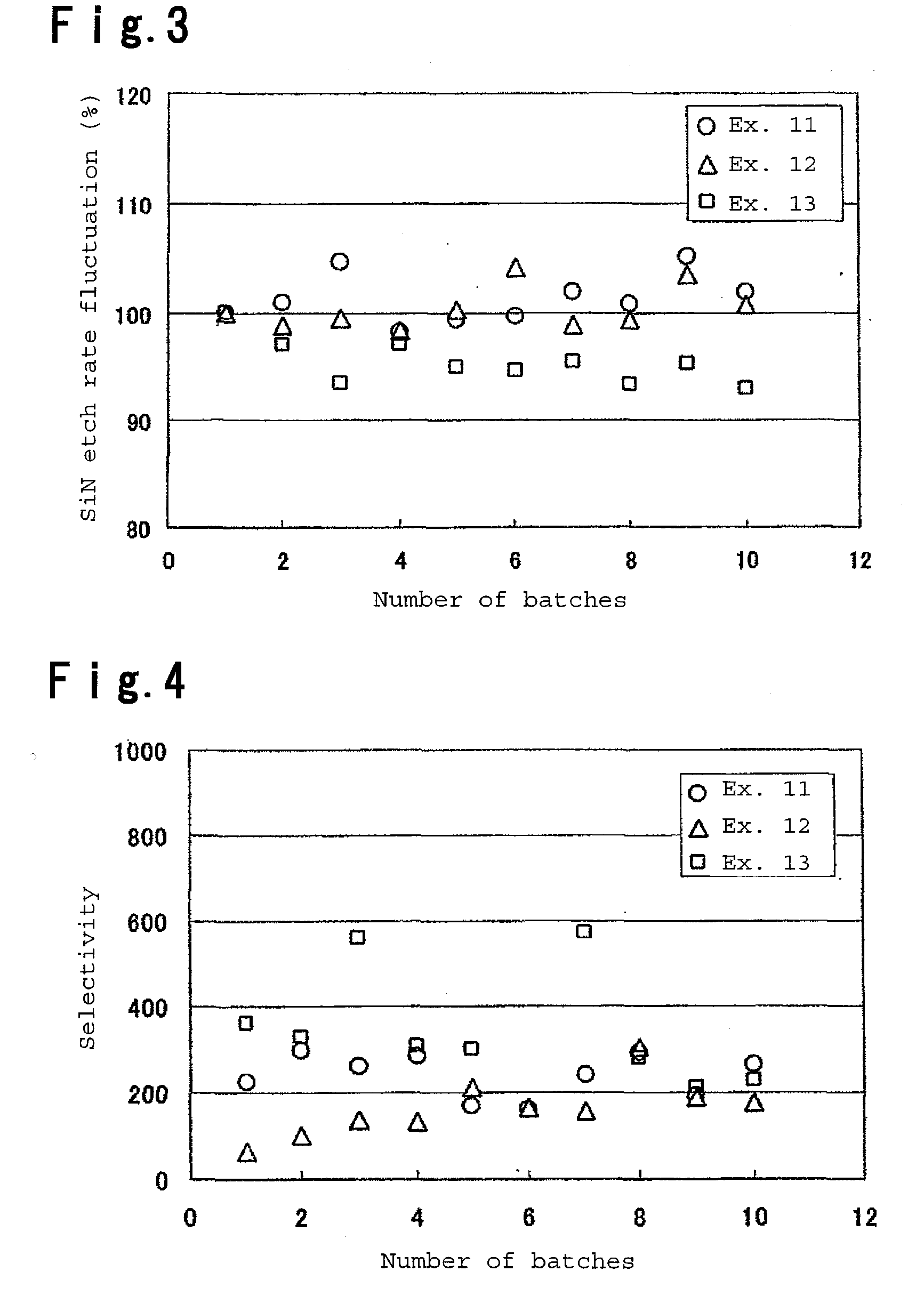

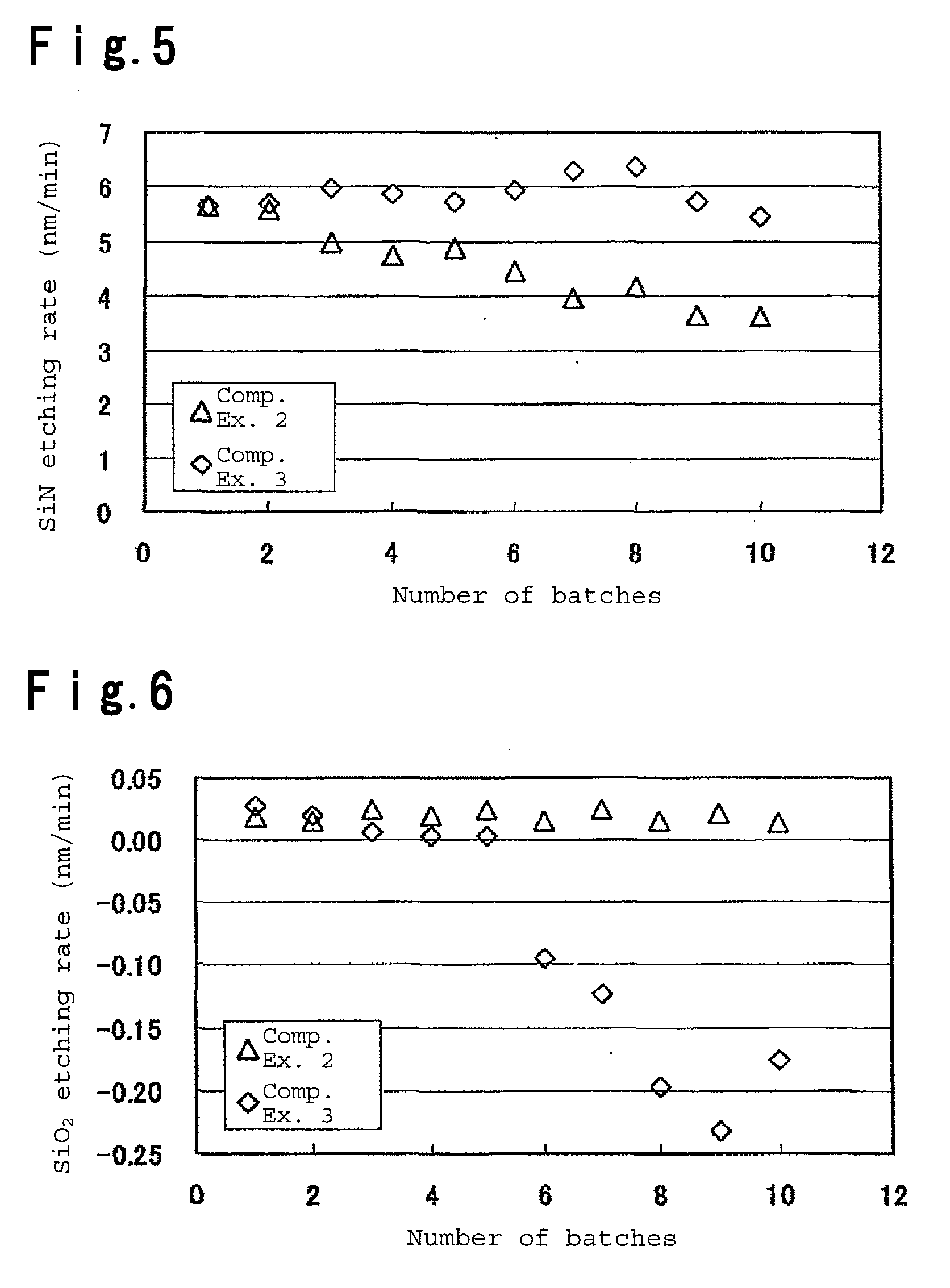

example 1

[0042]A silicon wafer (15 mm square) having SiN deposited in a thickness of 300 nm by a CVD method and a silicon wafer (15 mm square) having a thermally oxidized film formed in a thickness of 1,000 nm were immersed at 150° C. for 30 minutes in 100 g of an etching composition comprising 0.02% of fluoroboric acid, 0.002% of ammonia, 5% of water and the rest being phosphoric acid. The wafers were taken out, washed with water and dried, and then the film thicknesses of SiN and the thermally oxidized film were measured by an optical interferotype film thickness meter. This operation was regarded as 1 batch and was continuously repeated for 14 batches. In the 14th batch, the SiN etching rate was 6.10 nm / min, and the etching rate of the thermally oxidized film was 0.03 nm / min. Even in the 14th batch, no precipitation of silicon oxide was observed on the thermally oxidized film, and the thermally oxidized film was found to be slightly etched.

[0043]This etching composition initially started ...

example 2

[0044]Etching of silicon nitride was carried out under the same conditions as in Example 1 by using a composition having 0.03% of hexafluorosilicic acid further added to the composition in Example 1.

[0045]Even in the 14th batch, no precipitation of silicon oxide was observed.

[0046]The selectivity for silicon nitride to silicon oxide was 220 from the first batch and thus was high from the beginning.

example 3

[0047]Etching of silicon nitride was carried out under the same conditions as in Example 1 by using a composition wherein 0.02% of fluoroboric acid in the composition in Example 1 was changed to 0.02% of fluorophosphoric acid.

[0048]In the 14th batch, the SiN etching rate was 6.00 nm / min, and the etching rate of the thermally oxidized film was 0.06 nm / min. Even in the 14th batch, no precipitation of silicon oxide was observed on the thermally oxidized film, and the thermally oxidized film was found to be slightly etched.

[0049]This etching composition initially started in a state where it contained no soluble silicic acid, but immediately after the initiation of its use, the composition was in a state where it contained soluble silicic acid. The etching selectivity for silicon nitride to silicon oxide (silicon nitride / silicon oxide) in each batch was examined, whereby it was found to be 15 in the first batch but 100 in the 14th batch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com