Water conservancy gate structure with high safety and use method thereof

A safety and water conservancy technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as increased equipment operating costs, increased overall equipment costs, and pressure-bearing damage to screw drive pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

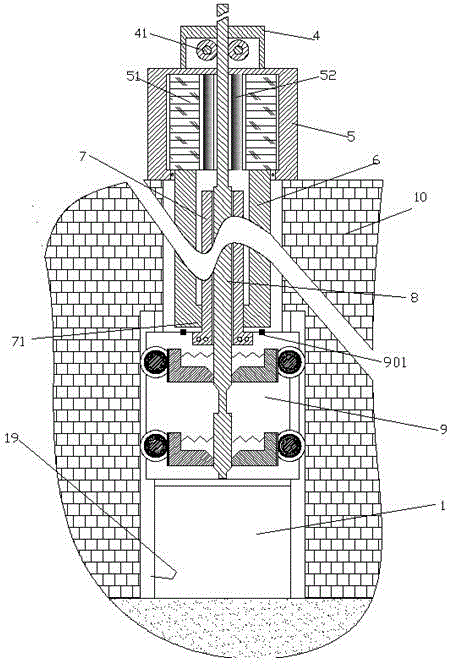

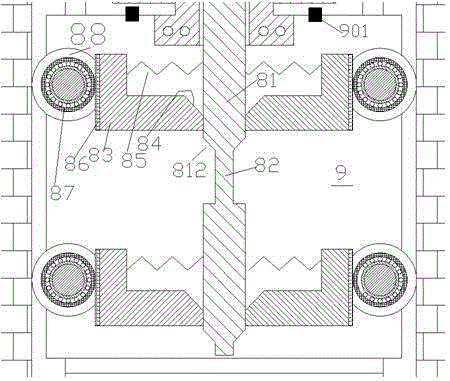

[0009] Combine below Figure 1-2 Embodiments of the present invention will be described in detail.

[0010] The water conservancy gate structure with high safety according to the embodiment includes a gate plate 9 for blocking the waterway opening 1, and an external threaded sleeve 7 is fixedly connected to the upper side of the gate plate 9 to extend into the hollow of the rotating shaft 6 Inside and threaded with the internal thread ring part 71 at the lower end, the upper end of the rotating shaft 6 is connected with the motor rotor 51 in the drive motor box 5 installed on the structural base 10, and the backwater side of the gate plate 9 is automatically Two roller support assemblies are installed from top to bottom, and each of the roller support assemblies includes two support rollers 88 that are installed on the left and right sides of the gate plate 9 respectively in the horizontal direction and are rotatable. The support roller 88 is used to cooperate with the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com