LED (light emitting diode) epitaxy structure and preparation method thereof

An epitaxial structure and buffer layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low wavelength yield, effectively release lattice mismatch warping, lattice stress, and low crystallinity, and achieve Avoid warpage effect and stress, improve photoelectric performance level, and achieve high wavelength yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

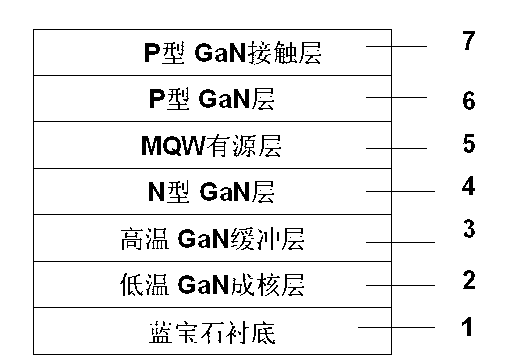

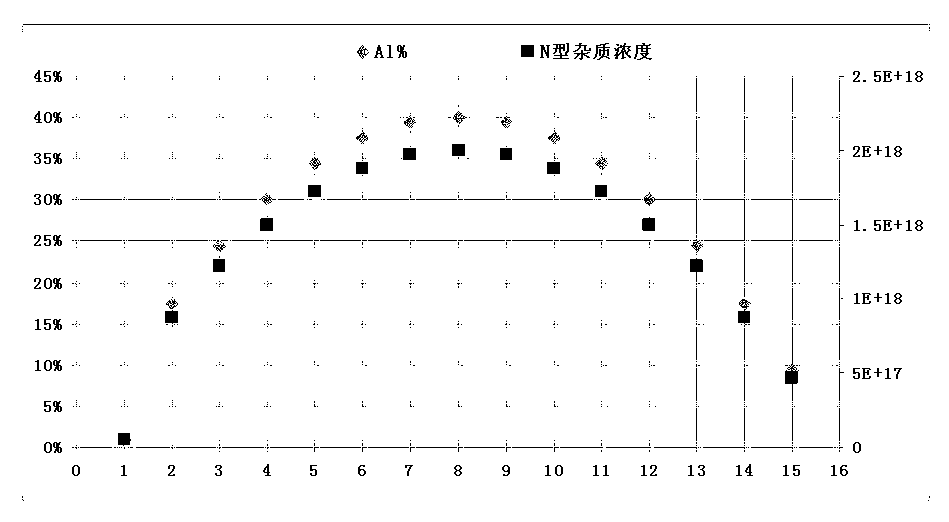

[0027] refer to figure 2 As shown, a kind of AlGaN / n-GaN superlattice bottom layer buffer layer LED epitaxial structure adopting Al composition of the present invention adopts parabolic linear gradient, can be different according to the actual process requirement and application substrate size, present the difference of different number of cycles. Superlattice underlying buffer layer structure with component distribution ratio, the cyclic logarithm ranges from 3 to 40 pairs, and the Al composition in the AlGaN layer ranges from 0% to 40%, and the thickness ranges from 0.1nm to 40nm Take a value between , and the corresponding doping concentration of n-type impurities in the paired n-GaN layer is 5×10 16 cm -3 to 1×10 19 cm -3 The thickness ranges from 0.3nm to 120nm, and the thickness ratio of AlGaN and n-GaN layers is between 1:5 and 1:1; in each AlGaN / n-GaN superlattice buffer layer, The Al composition and n-type doping concentration are uniquely determined by the Al co...

Embodiment 2

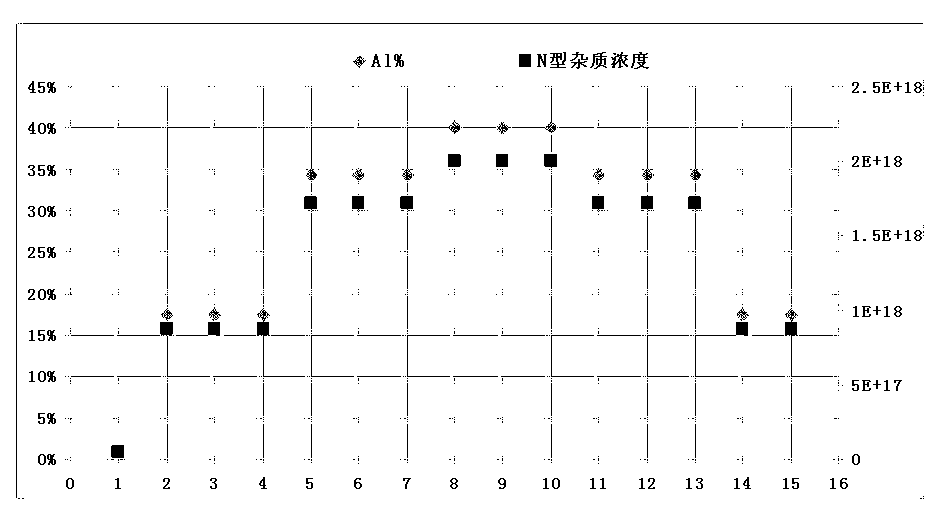

[0033] Different from the optimization scheme of the Al component and n-type impurity concentration ratio coefficient in Example 1 using a parabolic gradual change mode, this embodiment adopts the Al composition and n-type impurity concentration ratio coefficient to gradually increase and then gradually decrease in a stepwise manner. Define that each group of lattice buffer layer pairs is composed of several pairs of AlGaN / n-GaN superlattice buffer layer pairs, Al( m ) represents the m The Al composition value in the AlGaN / n-GaN superlattice buffer layer pair, N ( m ) represents the m The n-type impurity concentration value in the AlGaN / n-GaN superlattice buffer layer pair, Al ( m )and N ( m ) change trend satisfies the relational formula: Al( m ) = Yn *Al( m- 1), N ( m ) = Yn * M ( m- 1), where, Ym follow the parabolic equation , a is a fixed constant, M Represents the total number of groups consisting of several pairs of superlattice buffer layers, m On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com