Steel-bonded reinforcement method for steel structure

A technology for steel structure and bonding steel, which is applied in the directions of non-polymer adhesive additives, adhesives, adhesive types, etc., to achieve the effect of reducing downtime, easy implementation, and increased structural weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

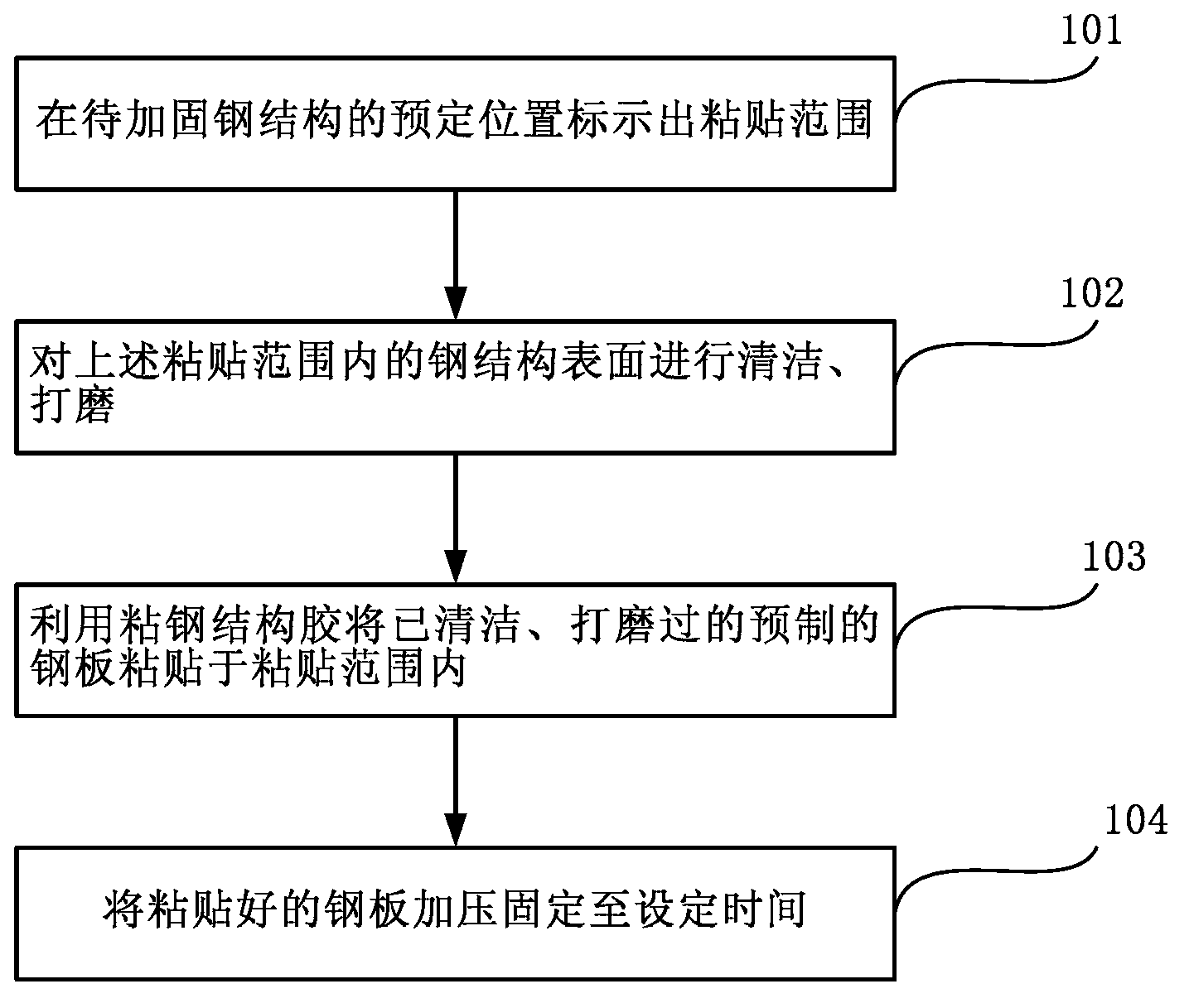

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] A steel structure bonding and reinforcement method, wherein the steel bonding structure adhesive includes two components A and B, wherein component A is composed of the following materials and parts by weight: 40-50 parts of fiber glue, 20 parts of bisphenol epoxy resin -30 parts, 1-2 parts of polyethylene polyamine; component B consists of the following materials and parts by weight: 10-11 parts of silicon powder, 2-3 parts of triethylenetetramine, 2-3 parts of cyclohexanone peroxide ; and include the following steps:

[0029] Step 1, marking the pasting range at the predetermined position of the steel structure to be reinforced;

[0030] Step 2, cleaning and polishing the surface of the steel structure within the above pasting range;

[0031] Step 3: Apply componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com