Preparation method of three-dimensional memory and preparation method of semiconductor structure

A memory, three-dimensional technology, applied in the field of memory, can solve the problems of interface metal contamination, easy loss of the top of the memory, and poor overall shape of the channel hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

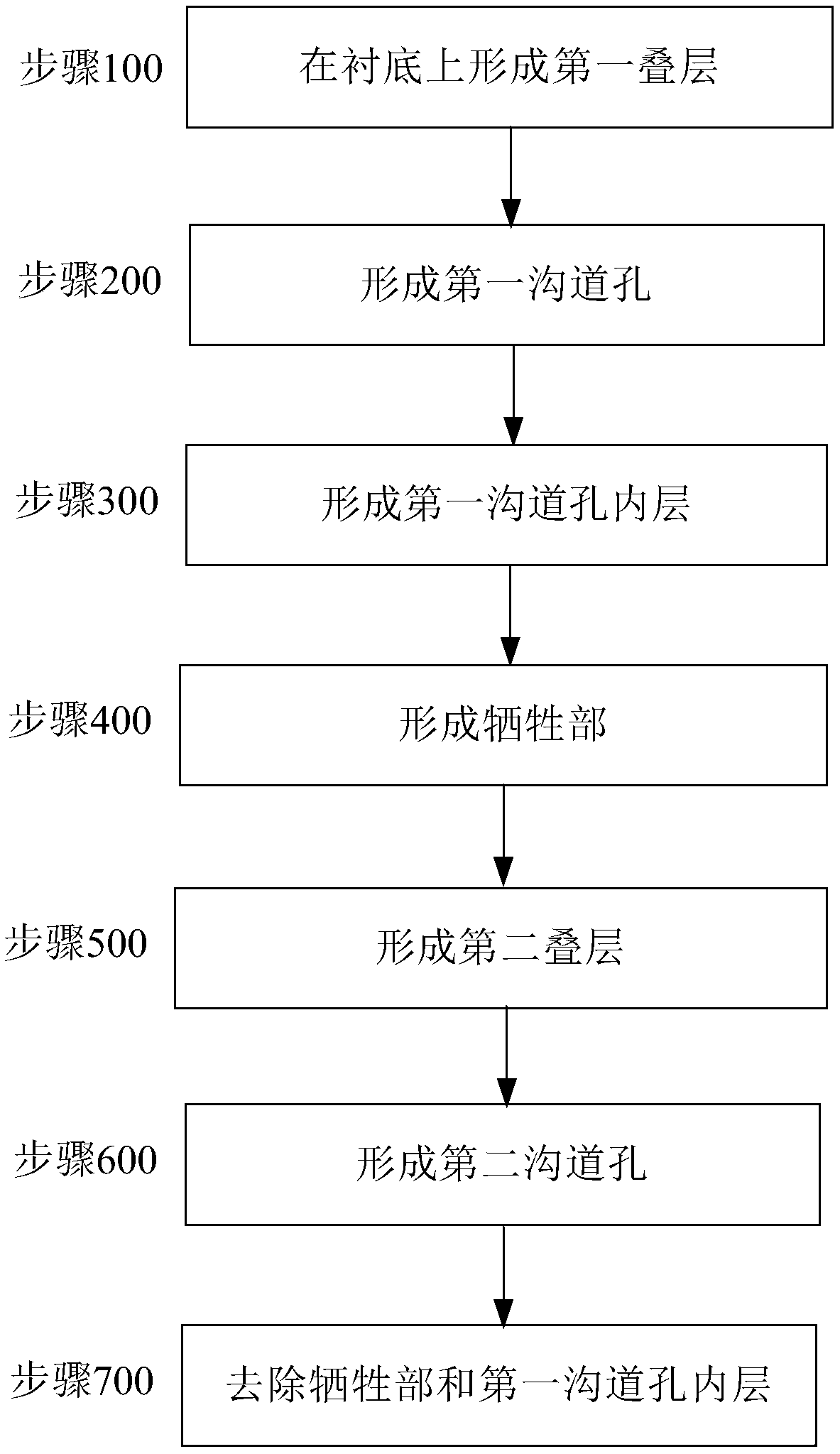

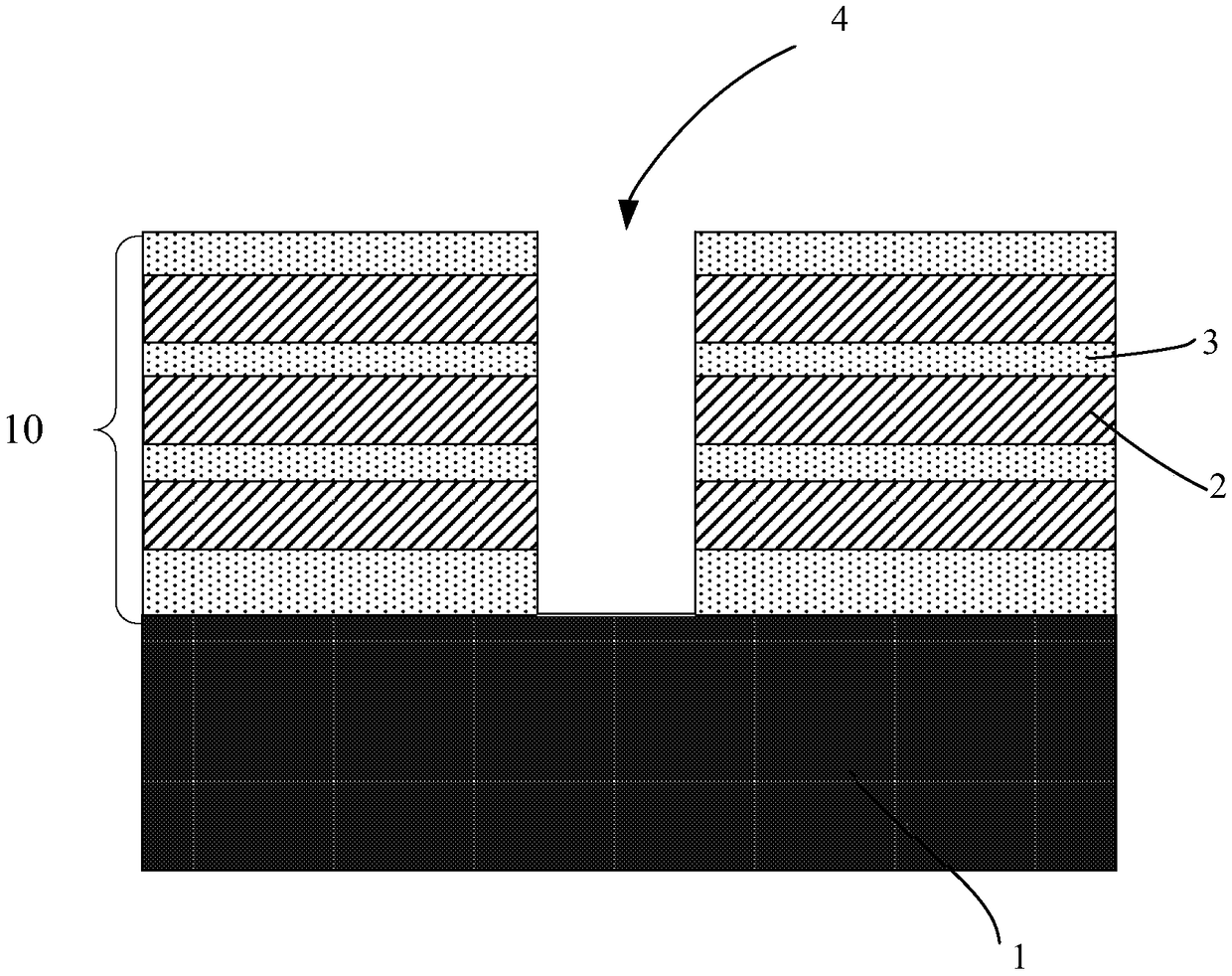

[0093] first reference figure 1 with Figure 2A to Figure 2G , an embodiment of the preparation method of the three-dimensional memory provided by the present invention is described. In the current embodiment, the method for preparing a three-dimensional memory provided by the present invention at least includes the following steps:

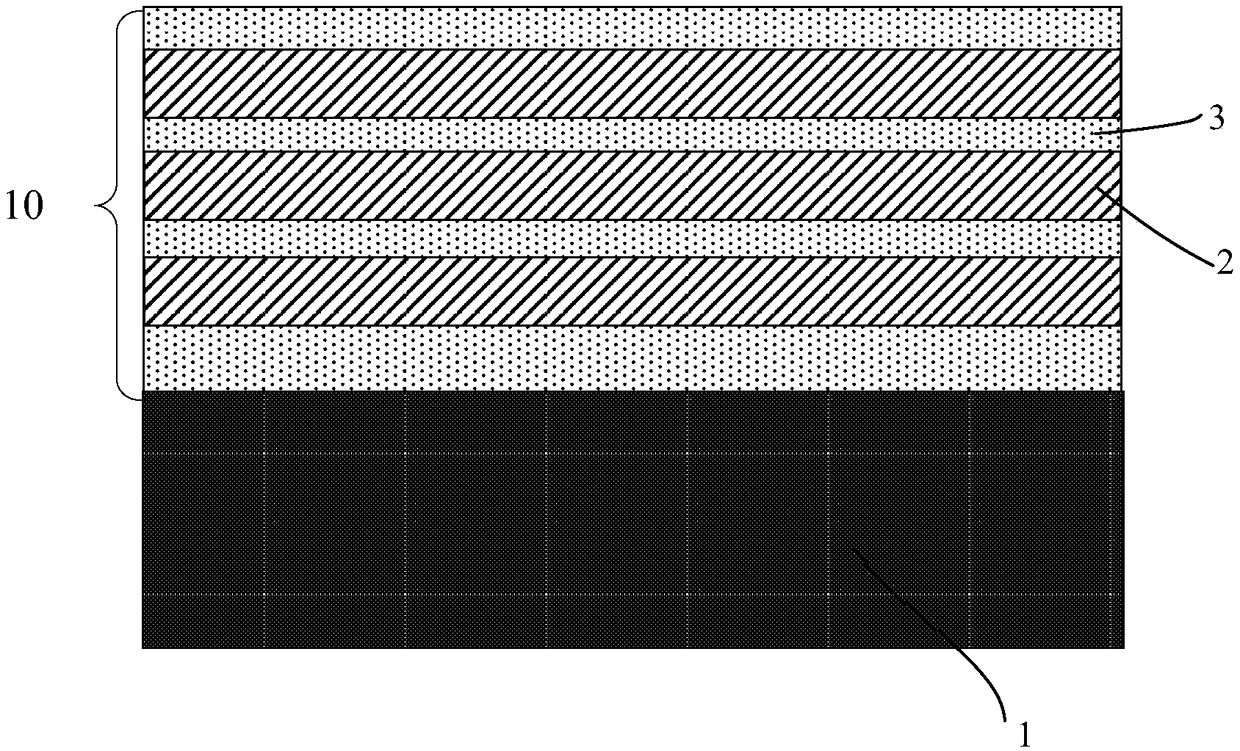

[0094] Step 100, refer to Figure 2A , forming a first stack 10 formed by alternately stacking the first layer 2 and the second layer 3 on the substrate 1 . In the present embodiment, the substrate 1 is made of single crystal silicon. But in other embodiments, the substrate 1 can also be made of other suitable materials, for example, in some embodiments, the material of the substrate 1 is silicon (single crystal silicon or polycrystalline silicon), germanium, silicon-on-insulator thin film ( Silicon on insulator, SOI), etc.

[0095] On the other hand, the first layer 2 and the second layer 3 may both be insulating layers, or may be an insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com