Three-dimensional elastic support

An elastic bearing, three-dimensional technology, applied in the direction of supporting machines, pipeline supports, machines/supports, etc., can solve problems such as large pipeline stress, damage to equipment and facilities, material waste, etc., to absorb or buffer vibration, reduce vibration, and apply Sexually wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

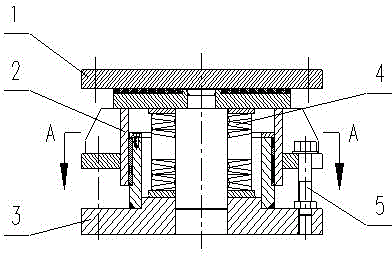

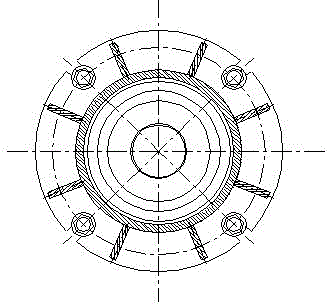

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Referring to Figure 1-4, according to the specific conditions of different types of equipment and facilities, a single equipment or facility can generally be used in combination with a single, two, four or six three-dimensional elastic bearings, and a steel structure frame can also be used if necessary As a basic frame, the equipment is placed on the basic frame as a whole, and the elastic support is placed under the basic frame. For example, the use of a single three-dimensional elastic support, a special pipe support that can be used as a single fulcrum support, etc.

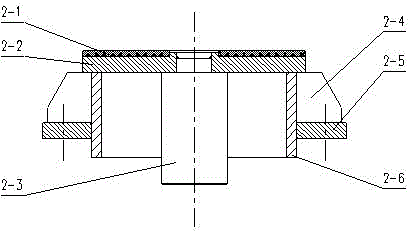

[0022] The sliding plate 1 of the three-dimensional elastic support is fixed to the bottom (or base frame) of the supported equipment with bolts or welding, and the equipment slides between the sliding plate 1 and the PTFE backing plate 2-1 of the top seat 2 to achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com