Trench MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and manufacturing method thereof

A manufacturing method and groove-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of unit cell spacing limitation and inability to further shrink, so as to avoid stress, facilitate filling, and prevent hollow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

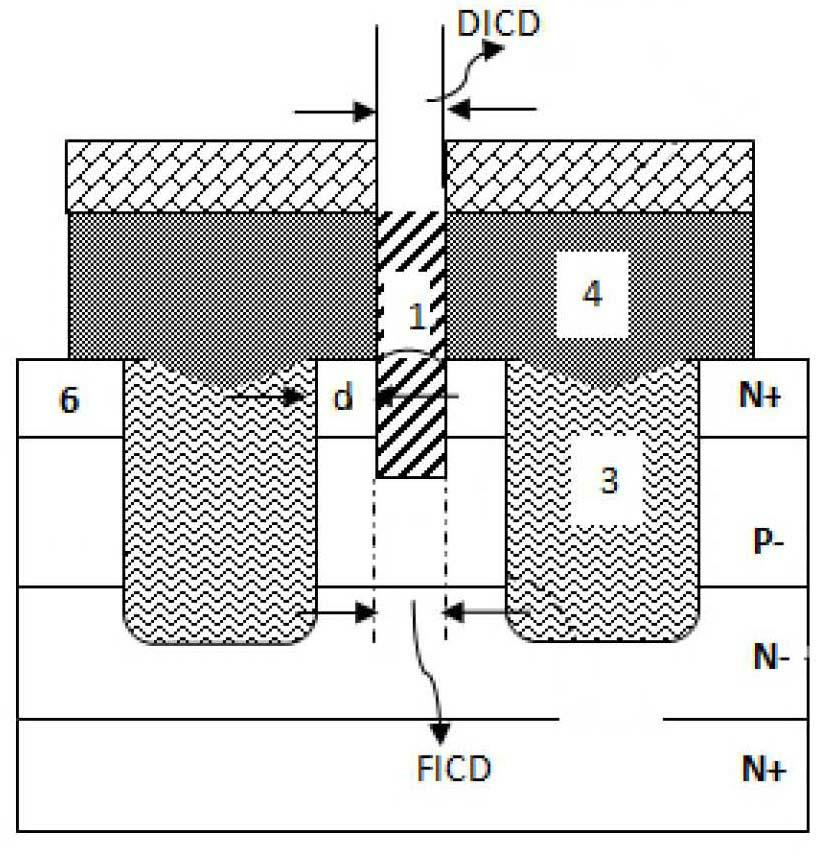

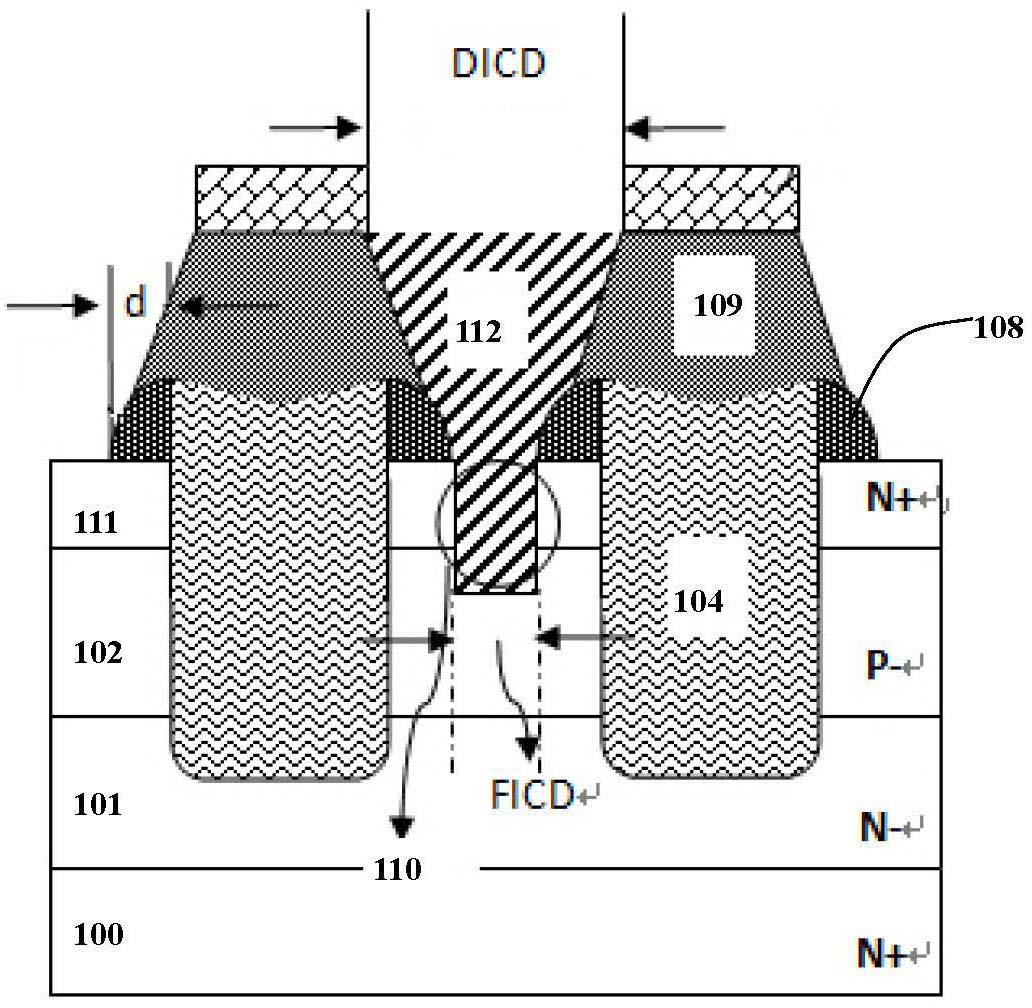

[0052] The main idea of the present invention is to set the source contact hole of the trench MOSFET into a shape with a large upper opening and a small lower opening, so that a small-sized source contact hole can be prepared by using a photolithography process with a larger line width, and can The pitch of the unit cell is further reduced, and the drain-source on-state resistance of the trench MOSFET is reduced.

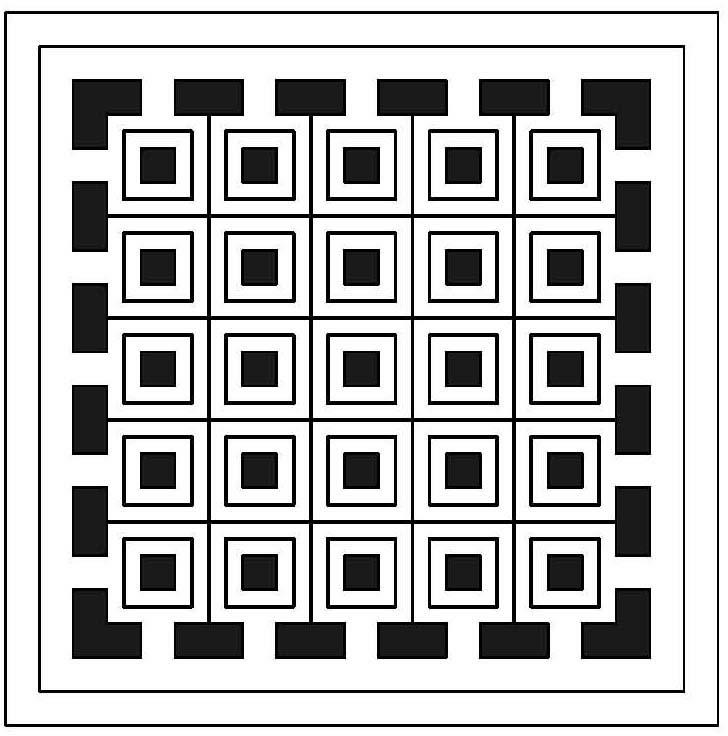

[0053] See figure 2 , which is an overall schematic diagram of the trench MOSFET of the present invention. The trench MOSFET is composed of a large number of unit cells 21 , each square structure in the figure is called a unit cell, and the distance between each unit cell is the distance between adjacent gates. The resistance of the channel under the gate of the unit cell is called the channel resistance, and the channel resistance is the most important parameter of the drain-source on-state resistance. When the drain-source of the MOSFET is turned on, the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com