An internal gate type MOS

A gate type, epitaxial layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large cell size, complex manufacturing process, large chip area, etc. , The effect of reducing the gate-drain capacitance Cgd and reducing Rdson

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

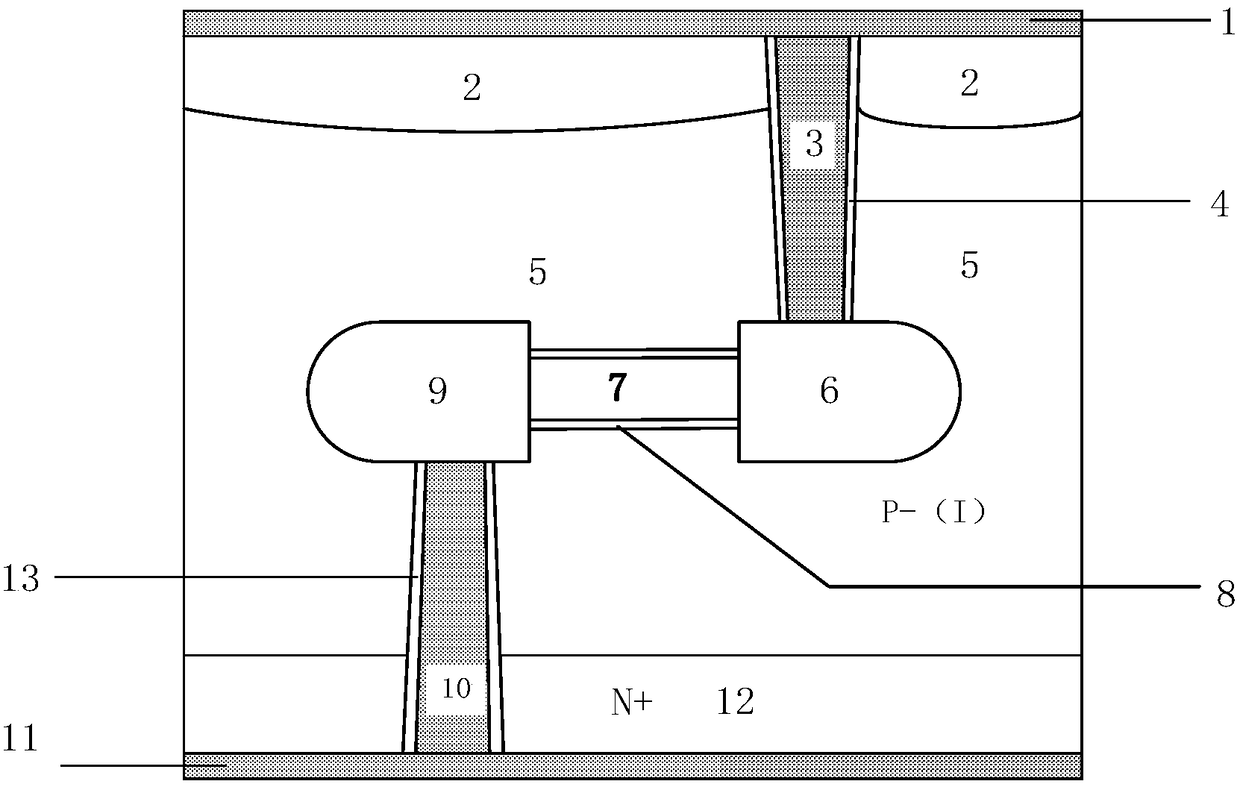

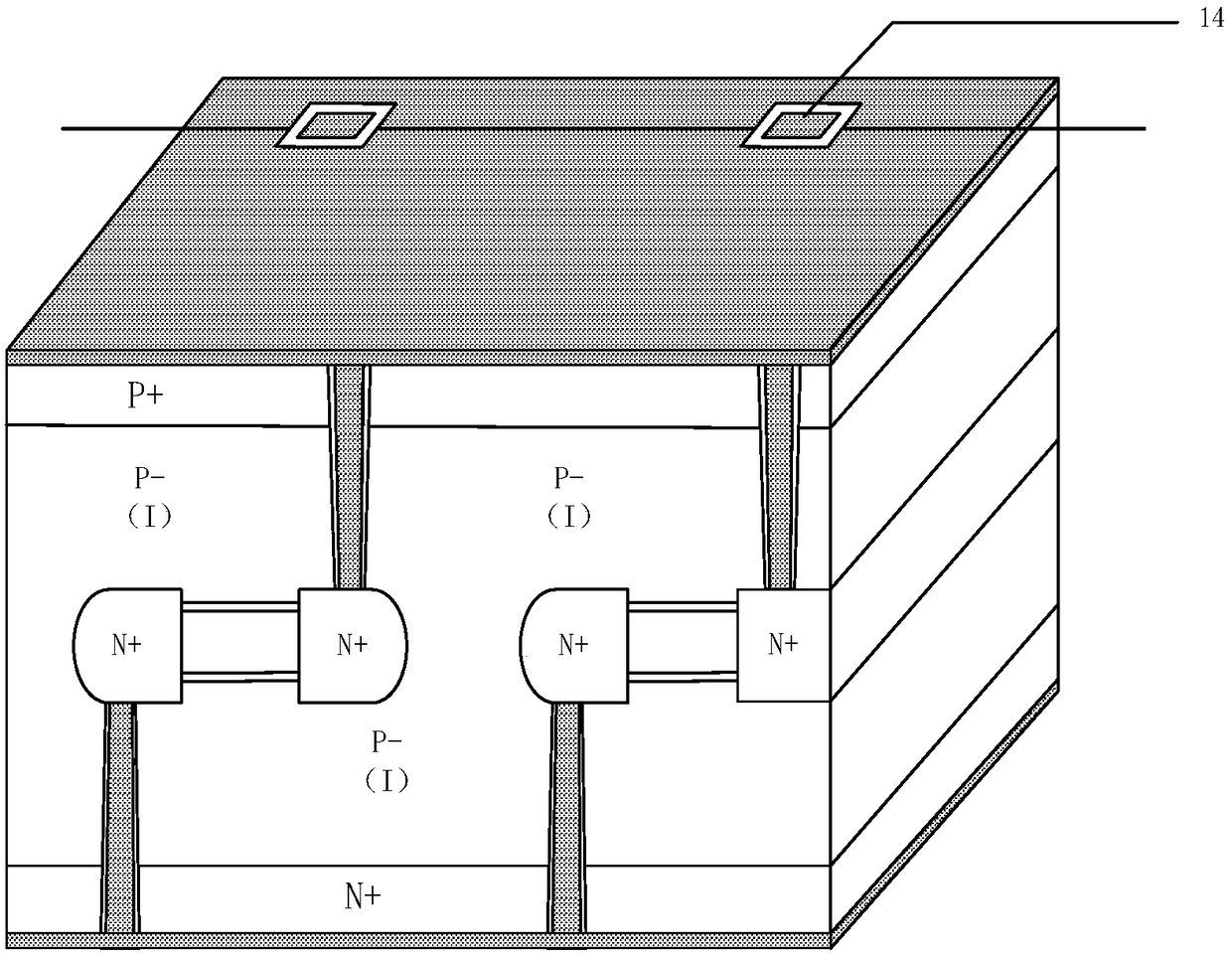

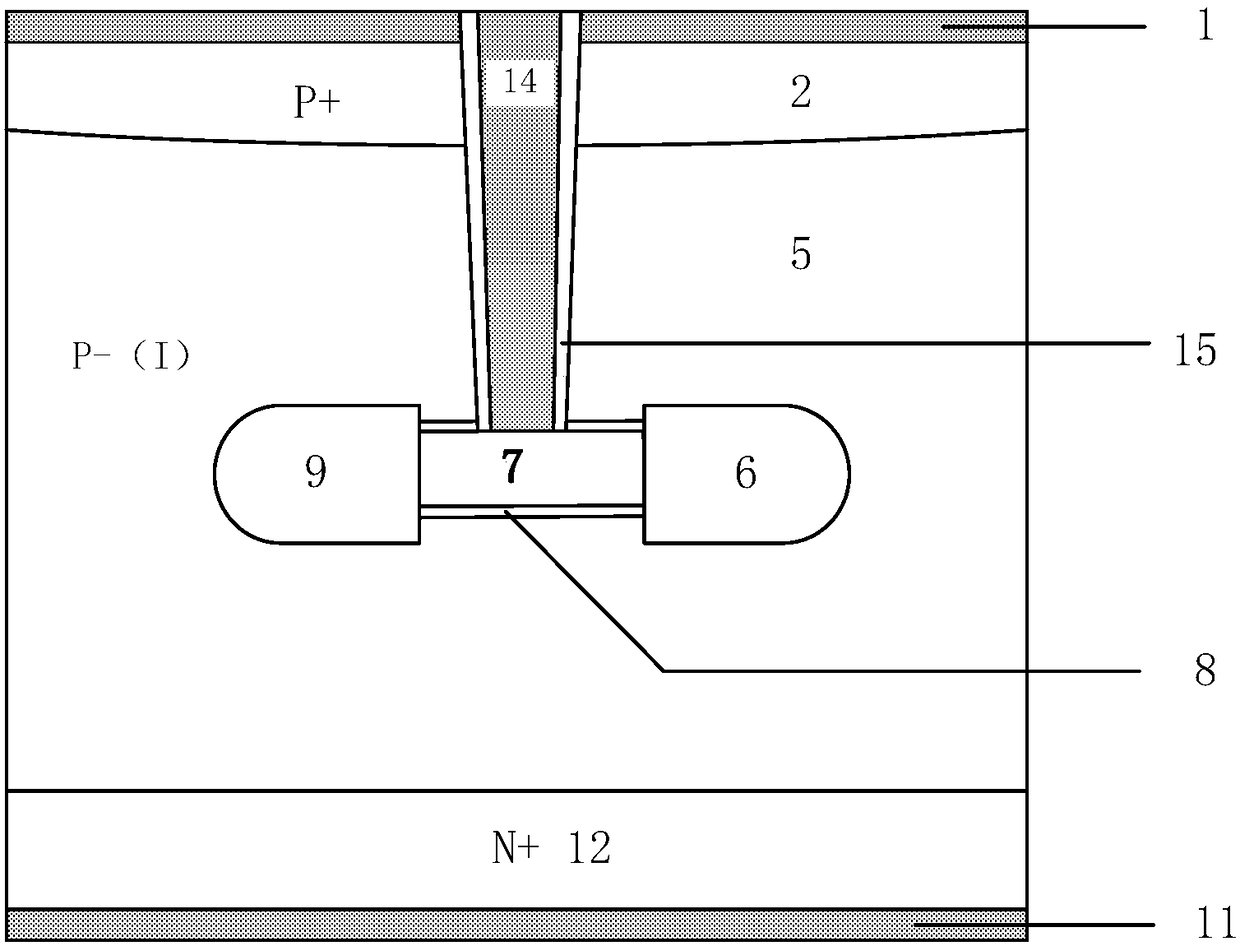

[0026] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing

[0027] Such as figure 1 As shown, an internal gate MOS of the present invention includes a drain electrode 11, an N-type heavily doped single crystal silicon substrate 12, a low-doped P-type epitaxial layer 5, a highly doped P+ source region 2 and source metal electrode 1; the doped P-type epitaxial layer 5 has a strip-shaped source region 6 and a strip-shaped drain region 9, and the strip-shaped source region 6 and strip-shaped drain region 9 are located on the same horizontal plane , and the strip-shaped source region 6 and the strip-shaped drain region 9 are connected by a polysilicon gate 7, and the polysilicon gate 7 is isolated from the low-doped P-type epitaxial layer 5 by a gate oxide layer 8; the strip-shaped source region 6 is connected by The first deep groove metal 3 that runs through the highly doped P+ source region 2 is connected to the source me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com