Shield tunnel segment joint stress in-situ measurement method

A technology of shield tunnel segments and shield tunnels, which is applied in the field of on-site monitoring and evaluation of segment joint sealing and mechanical behavior, and can solve the problems of difficult measurement, quantification and effective evaluation of joint pressure, joint sealing The performance is not easy to detect and other problems, to achieve the effect of overcoming the difficulty of monitoring, realizing performance early warning, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

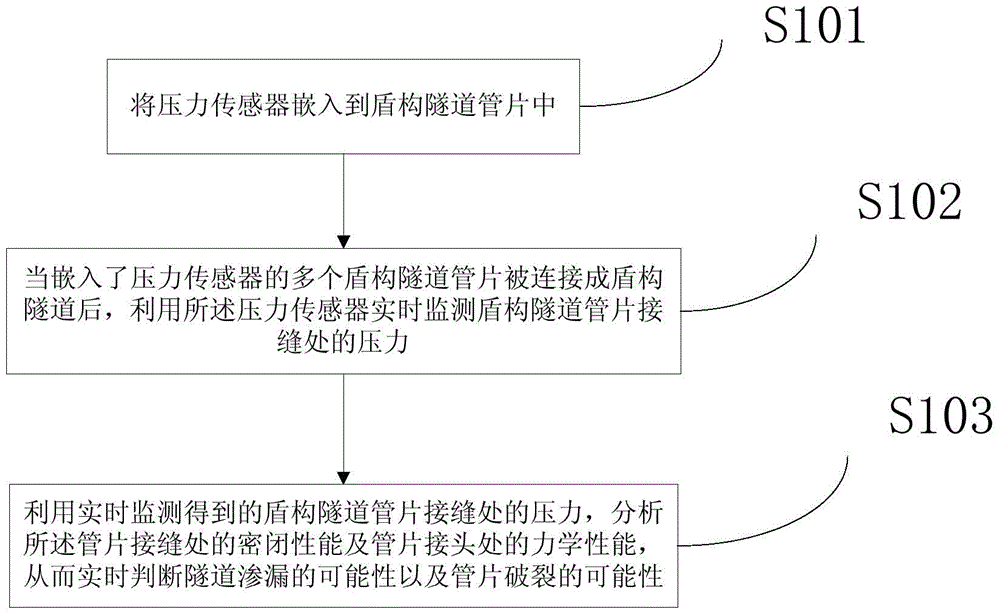

[0042] Such as figure 1 The operation steps of the in-situ measurement method for the force of a shield tunnel segment joint of the present invention shown include:

[0043] Step S101 , embedding the pressure sensor inside the segment of the shield tunnel, and at the bottom of the outer groove where the rubber sealing strip is installed, so that the pressure sensor and the segment become a whole and jointly bear force.

[0044] Further, the pressure sensor is an optical fiber grating sensor, and the shield tunnel segment is made by pouring concrete, so that the optical fiber grating pressure sensor and the shield tunnel segment are poured into one body.

[0045] Wherein, the maximum range of the fiber grating pressure sensor is slightly larger than the predicted pressure value at the segment joint.

[0046] Further, the making of the shield tunnel segment by pouring concrete, and making the fiber grating pressure sensor and the shield tunnel segment integrally include: before...

Embodiment 2

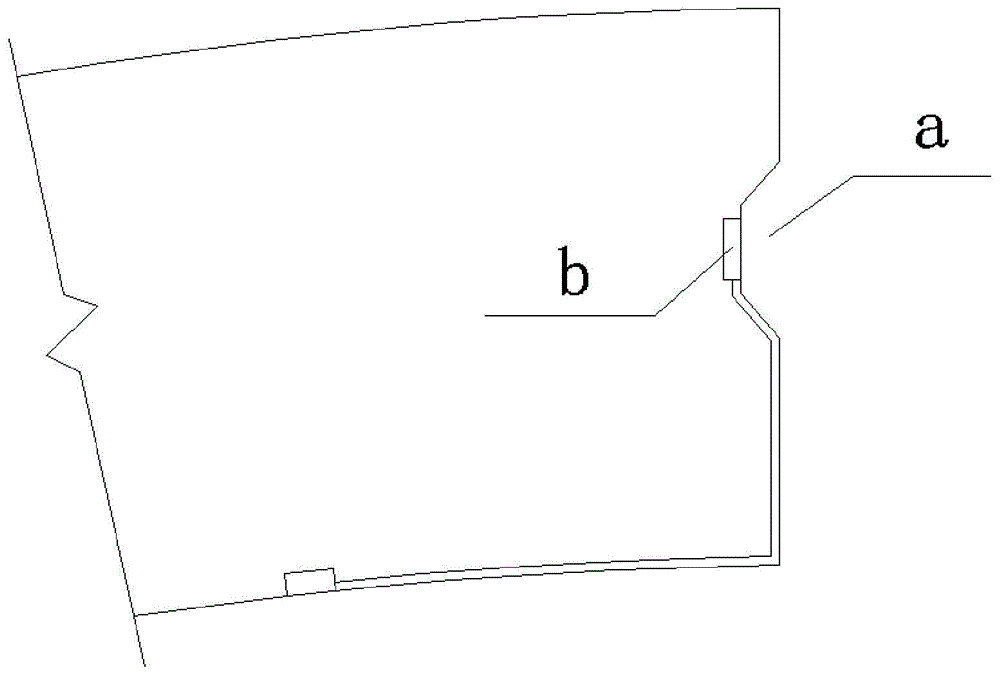

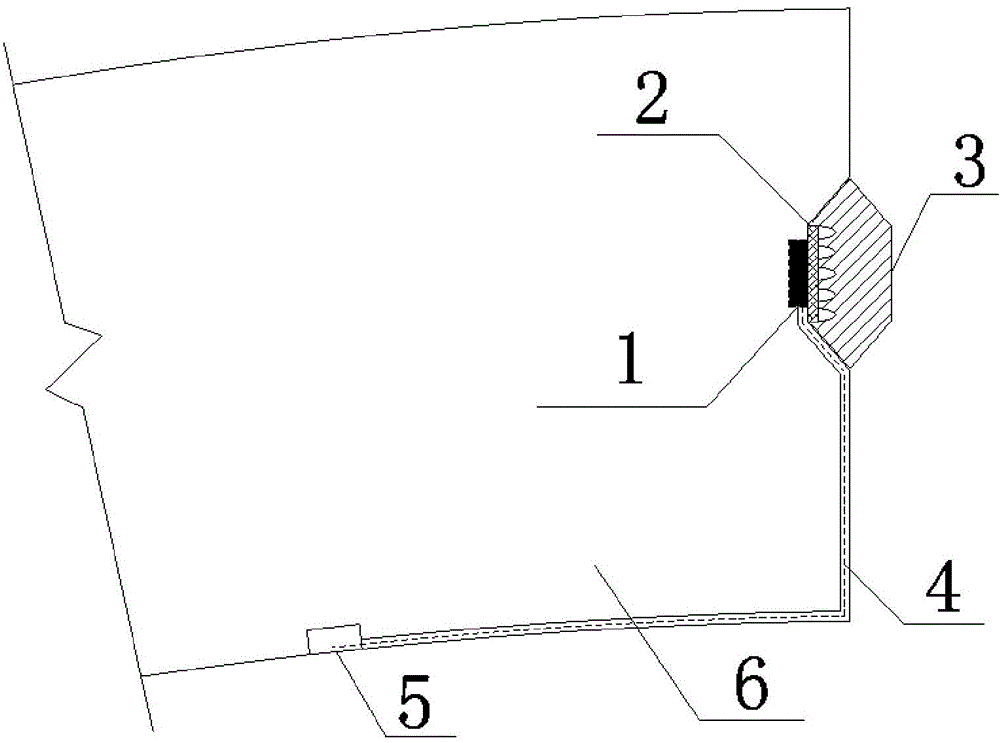

[0058] Such as Figure 2-6 The schematic diagram of the structure of the shield tunnel segment seam obtained by the method of the present invention includes: a pressure sensor 1 embedded in the shield tunnel segment 6, installed at the inner groove b, the pressure The force surface of the sensor is located at the same level as the side of the shield segment; the rubber sheet 2 arranged on the force surface of the pressure sensor is used to protect the pressure sensor from corrosion and damage; it is attached to the rubber sheet 2 , the rubber sealing strip 3 installed on the side of the segment, the rubber sealing strip 3 is installed in the inner groove a; the connecting wire 4 for transmitting optical signals, one end is connected with the pressure sensor, and the other end is connected with the The connection of the monitoring device; the reserved slot 5 for connecting wires for laying out the connecting wires.

[0059] Wherein, the pressure sensor is an optical fiber grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com