Method and device for performing tunnel advance borehole penetration-scribing test by using probe

An advanced drilling and penetrating technology, which is applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, mining devices, etc., can solve the problem of scattered, unable to directly use drilling, and unable to obtain continuous evolution profiles of surrounding rock strength and other problems, to achieve the effect of convenient operation and easy engineering field application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

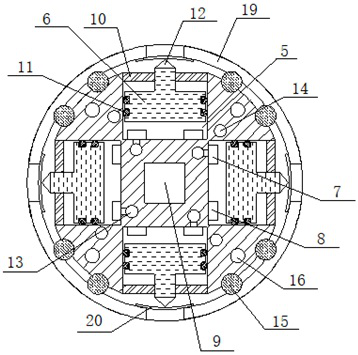

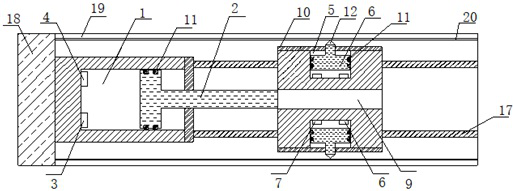

[0032] Such as figure 1 , 2 As shown, the embodiment of the present invention provides a probe for tunnel advance drilling penetration-marking test, including an axial loading device and a radial loading device.

[0033] The radial loading device is used for applying radial pressure to the borehole walls at different depths and at different positions, and collecting radial pressure and radial displacement data.

[0034] The axial loading device is used to apply axial pressure to the radial loading device under the condition of applying radial pressure to the borehole wall, and collect axial pressure and axial displacement data.

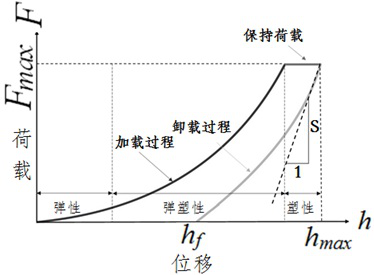

[0035] During the penetration test using the probe with the above structure, it can be placed at any depth position of the borehole according to preset, and the radial loading device can exert pressure on the borehole wall along the radial direction of the borehole. Among them, the applied radial pressure can be loaded step by step or constant. By a...

Embodiment 2

[0097] An embodiment of the present invention provides a device for tunnel advance drilling penetration-marking test, including the probe described in Embodiment 1, and also includes a pressurizing device and a data acquisition device, the pressurizing device is used for The axial loading device and radial loading device in the probe provide pressure and recovery pressure; the data acquisition device is used to collect the axial displacement sensor, axial pressure sensor, radial displacement sensor and radial pressure in the probe sensor data.

[0098] Wherein, the probe is connected with the pressurizing device and the data acquisition device through pipelines, electric wires and / or data lines to realize liquid flow, power supply and data transmission.

[0099] The specific structure of the probe and the method of using the probe to perform the penetration test and the scratch test can refer to the description in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com