Brazing method for ZrB2-based material

A connection method and base material technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of low strength of brazed joints, achieve the improvement of joint shear strength, relieve joint stress, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

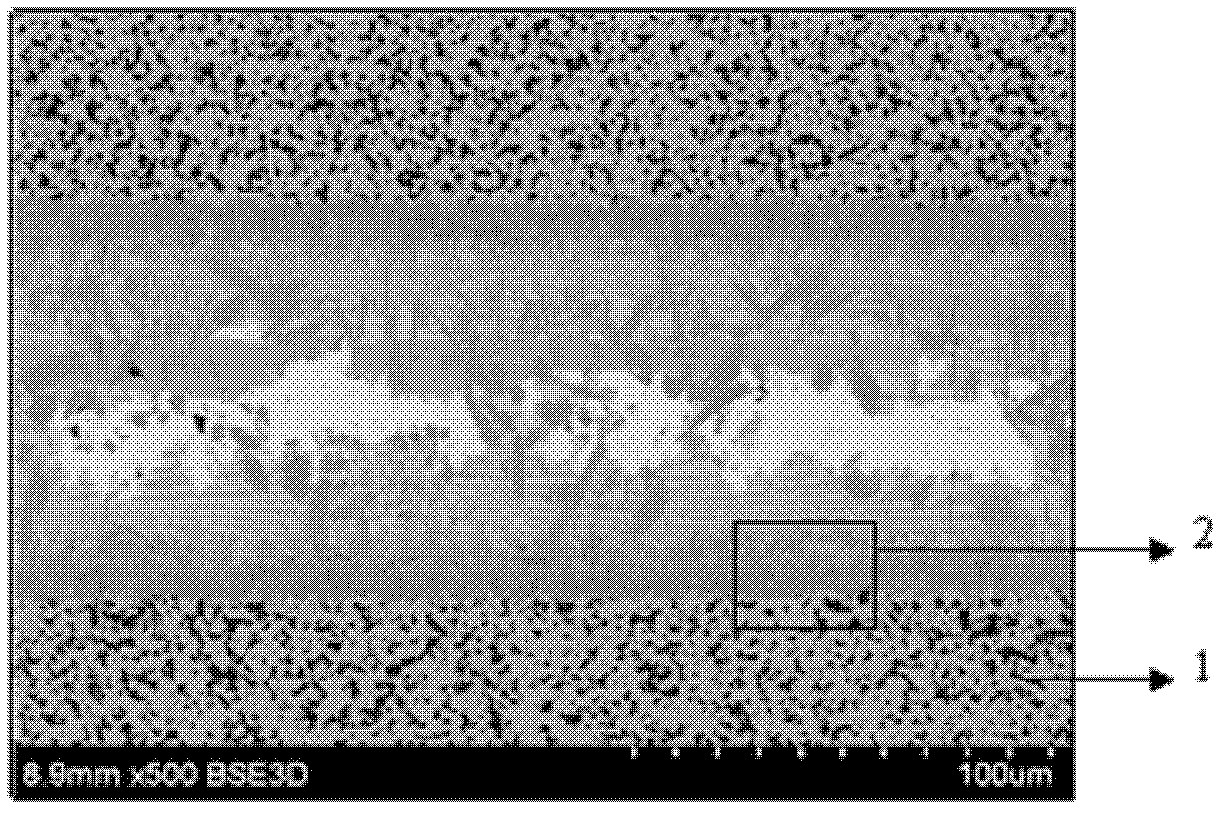

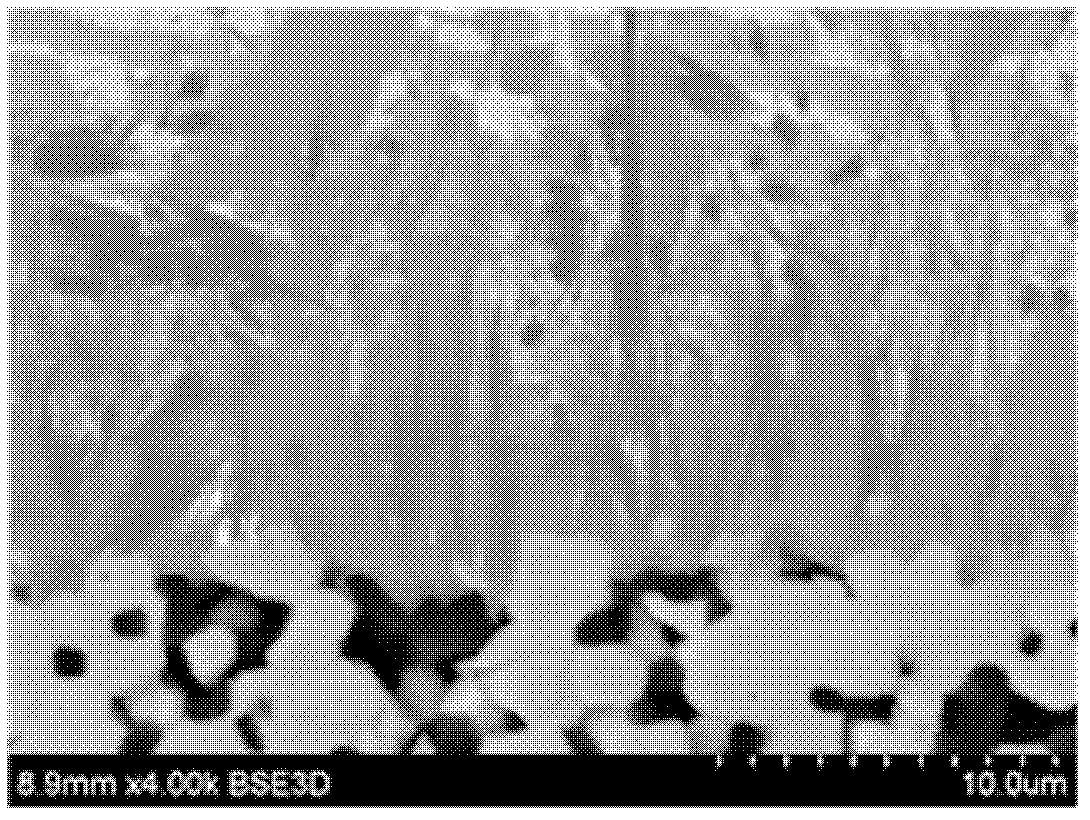

[0018] Specific implementation mode one: ZrB described in this implementation mode 2 The brazing connection method of the base material is carried out in the following steps: 1. Weigh 10wt.% to 50wt.% of Ti powder and 50wt.% to 90wt.% of Ag-Cu eutectic powder by mass percentage, and put them into a ball mill jar , under the protection of Ar gas, ball milling at a speed of 300r / min to 350r / min for 1h to 5h to obtain a composite solder; 2. ZrB 2 After the base material and the connecting parts to be connected with it are polished, they are ultrasonically cleaned with acetone for 5 minutes to 10 minutes, and then dried for use; 3. The composite solder and binder obtained in step 1 are processed according to the volume ratio of 1:0.5~2 After stirring and mixing, apply evenly on ZrB 2 The base material and the surface of the connector to be connected with it are the parts to be welded; 4. The parts to be welded obtained in step 3 are placed in a vacuum brazing furnace, and the vac...

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 15wt.% to 40wt.% of Ti powder and 60wt.% to 85wt.% of Ag-Cu eutectic powder are weighed according to mass percentage . Others are the same as in the first embodiment.

[0021]The preferred embodiment of this embodiment is to weigh 15wt.% Ti powder and 85wt.% Ag-Cu eutectic powder according to mass percentage.

specific Embodiment approach 3

[0022] Specific implementation mode three: ZrB described in this implementation mode 2 The brazing connection method of the base material can also be carried out according to the following steps: 1. Ti foil and Ag-Cu eutectic foil are stacked with a thickness ratio of 0.21 to 1.12:1, which is brazing foil; 2. ZrB 2 After the base material and the connectors to be connected with it and the solder foil prepared in step 1 are polished, they are ultrasonically cleaned with acetone for 5 to 10 minutes, then dried, and then the ZrB 2 The base material, brazing material foil and connectors are superimposed to form the workpiece to be welded; 3. Place the workpiece to be welded obtained in step 2 in a vacuum brazing furnace, and vacuum the vacuum brazing furnace to 5×10 -4 ~1×10 -3 Pa, then raise the temperature of the vacuum brazing furnace to 750°C at a speed of 15°C / min, and keep it for 5 minutes, then raise the temperature at a speed of 10°C / min to 840°C~980°C, keep it for 5~20mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com