Design method of high-voltage DC cable intermediate joint stress cone

A technology of cable intermediate joints and design methods, which is applied in the direction of cable accessories, cable installation, electrical components, etc., can solve the problems related to electrical conductivity and achieve the effect of uniform distribution of tangential field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

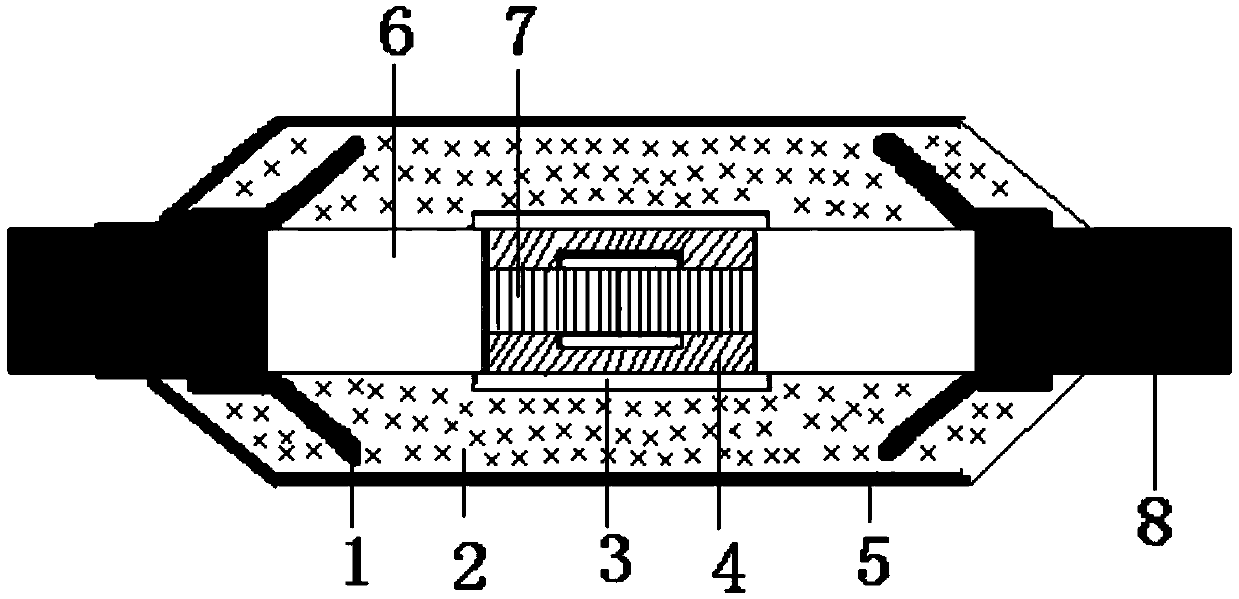

[0037] figure 1 It is a schematic diagram of the overall prefabricated accessory structure. The intermediate joint is reinforced insulation shield 5, reinforced insulation 2, and cable insulation layer 6 from outside to inside; the connection between cables is stripped of cable insulation shield 8 and cable insulation layer 6 The cable conductor 7 is fixed by the connecting fitting 4, and the outside of the connecting fitting 4 is covered with a high-voltage shielding tube 3; the stress cone semi-conducting part 1 in the accessory is located in the reinforced insulation 2.

[0038] The material used for the reinforced insulation 2 is silicone rubber (SIR), and the material used for the cable insulation layer 6 is cross-linked polyethylene (XLPE).

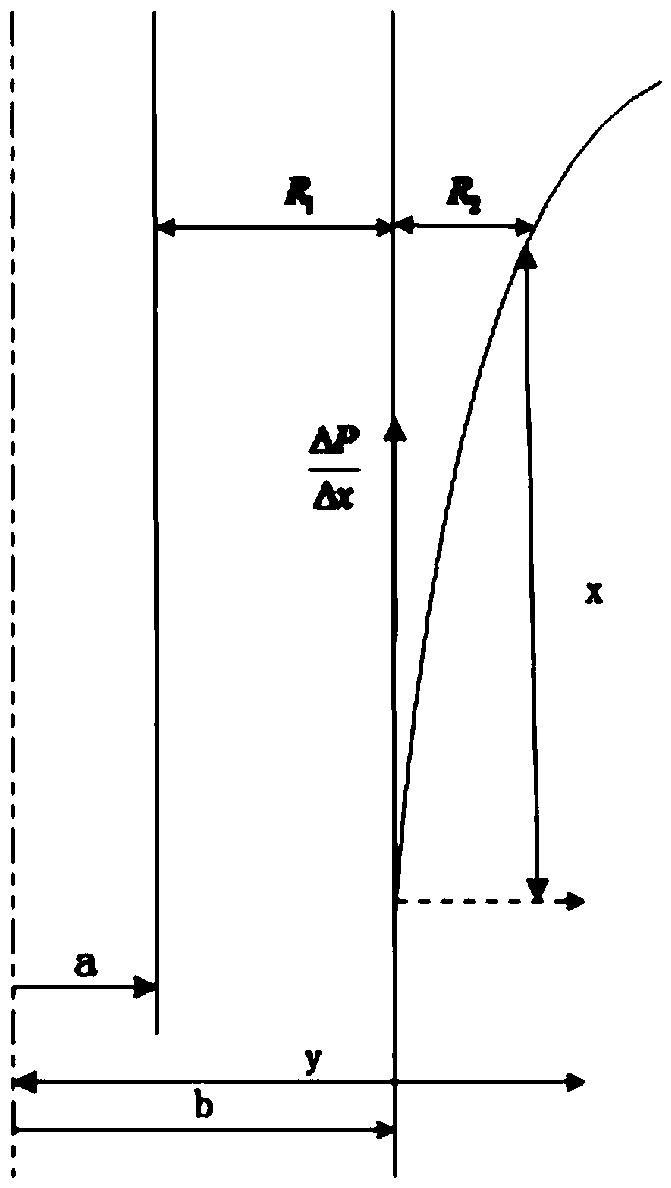

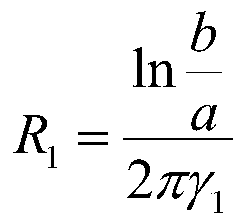

[0039] attached figure 2 It is the principle explanatory diagram of this embodiment, and the prefabricated acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com