Silvalin plying device and method for improving mechanical properties of fiber reinforced composite materials

A composite material, fiber-reinforced technology, applied in yarn, textile and papermaking, etc., can solve the problems of different lengths, easy twisting of fiber strands, etc., to achieve the effect of controlling, ensuring consistency and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

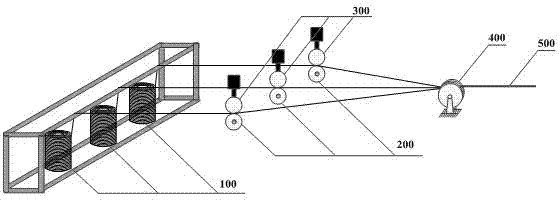

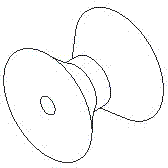

[0021] Example: see figure 1 , figure 2 and image 3 . figure 1 It is a structural schematic diagram of the damping tension control device used to ensure the length consistency of the fiber precursors before plying, including the precursor cylinder 100, the tension control wheel 200, the pressing wheel 300 and the plying wheel 400. After each fiber precursor is pulled out from the precursor tube, it enters the corresponding tension control device respectively. The tension control device includes two parts: the tension control wheel 200 and the pressure wheel 300; The filaments are subjected to uniform tension, and finally enter the ply wheel 400 for plying to obtain ply yarn 500.

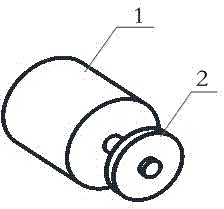

[0022] figure 2 It is a schematic diagram of a tension control wheel 200 with a damping control device. The tension control wheel is composed of a damping control device 1 and a tension wheel 2. The damping control device 1 uses an electromagnetic damper or other types of dampers. Set differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com