Cast-in-place prefabricated composite structure pile suitable for karst zone and construction method of cast-in-place prefabricated composite structure pile

A technology of combined structure and construction method, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as high cost, inability to take out, construction personnel casualties, etc., and achieve obvious economic benefits, fast construction speed, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with the accompanying drawings. The following is only an example of the technical solutions of the present invention, and does not represent the scope of all technical solutions of the present invention. In addition, the terms used in the embodiments have clear definitions, which are subject to their definitions, and there is no clear definition. The general explanations in the industry shall prevail, and the structure or steps not mentioned in the following embodiments are existing mature technologies.

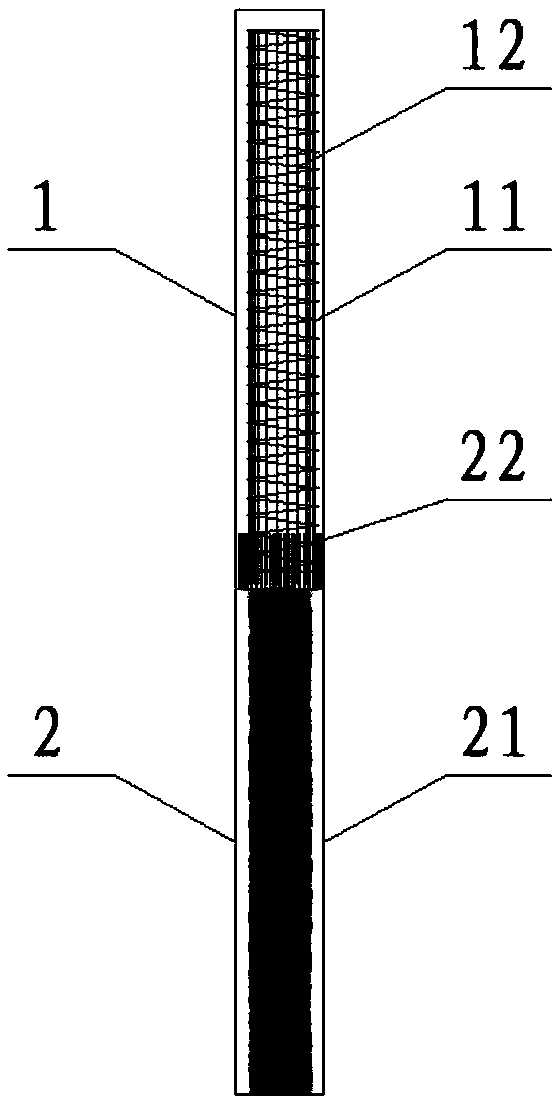

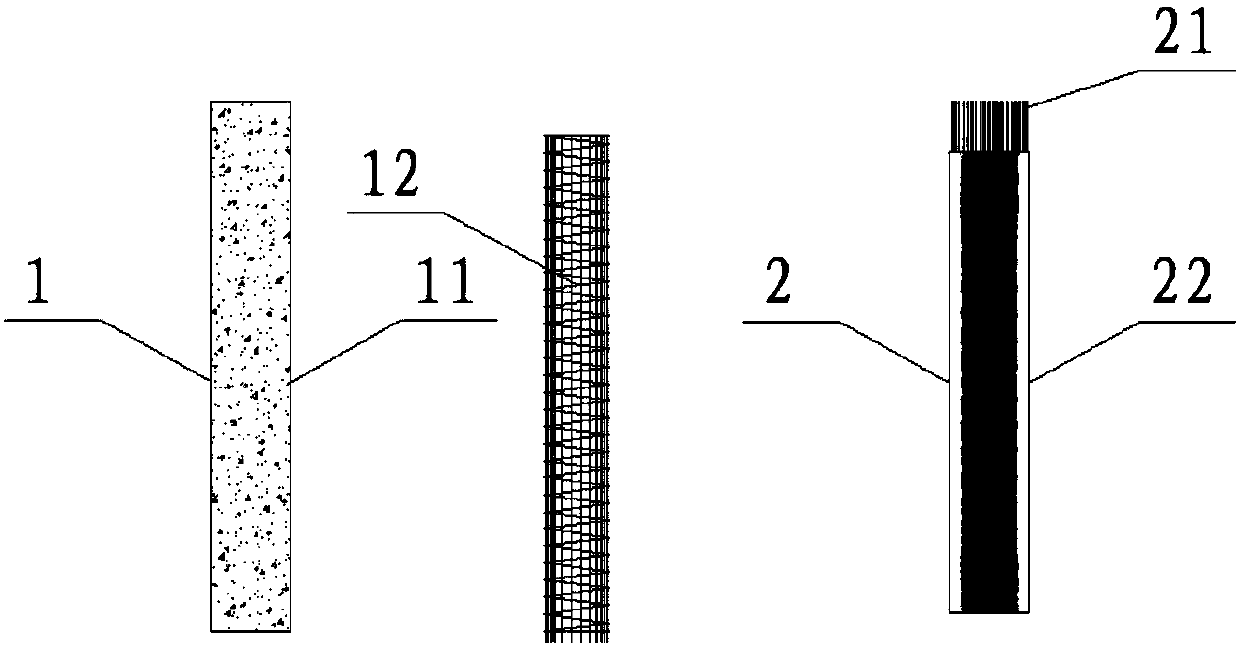

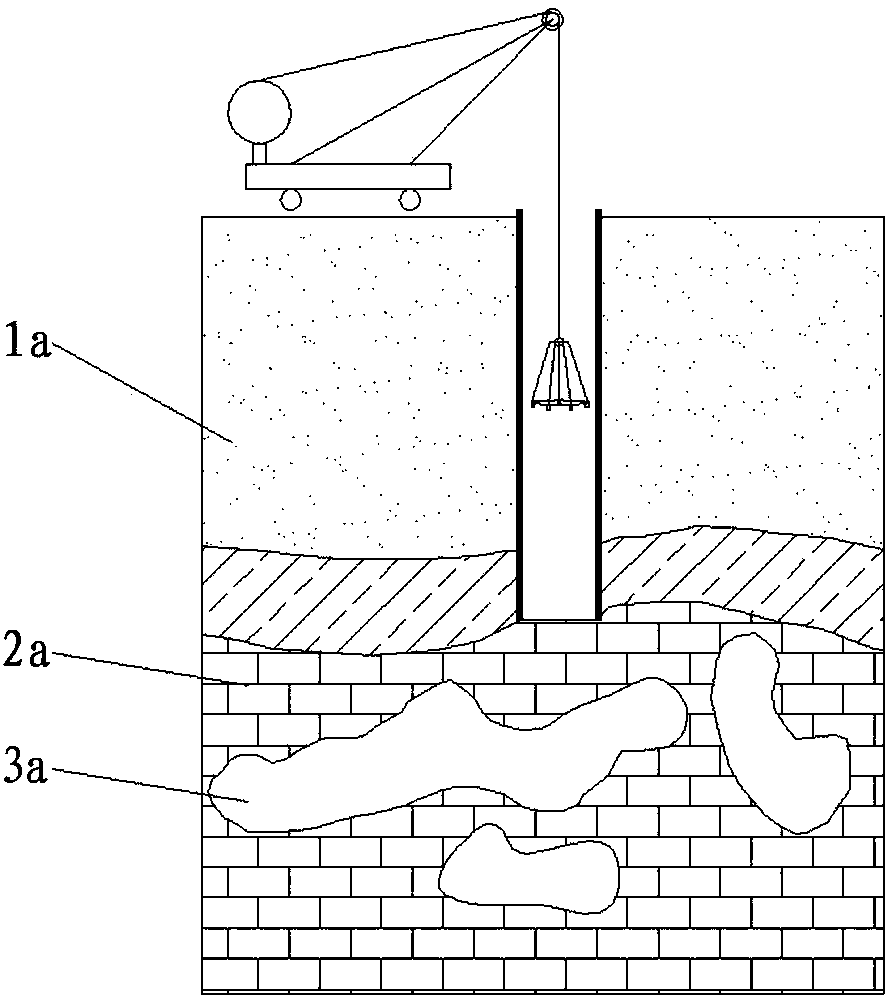

[0030] Such as figure 1 and figure 2 As shown, a cast-in-place prefabricated composite structural pile suitable for karst areas includes an upper section pile 1 and a lower section pile 2, the upper section pile 1 is a cast-in-situ reinforced concrete pouring pile 11, and the lower section pile 2 is a prefabricated concrete pipe pile 22, The lower pile 2 passes through the karst cave area 2a in the rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com