Design and manufacturing method of polyether-ether-ketone bionic multilevel artificial joint

A technology of artificial joints and polyether ether ketone, which is applied in the directions of processing and manufacturing, additive manufacturing, and manufacturing tools, can solve the problems of unsuitability, high internal hardness, single material and PEEK, etc., so as to avoid the stress shielding effect and reduce the The effect of joint loosening and avoiding artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

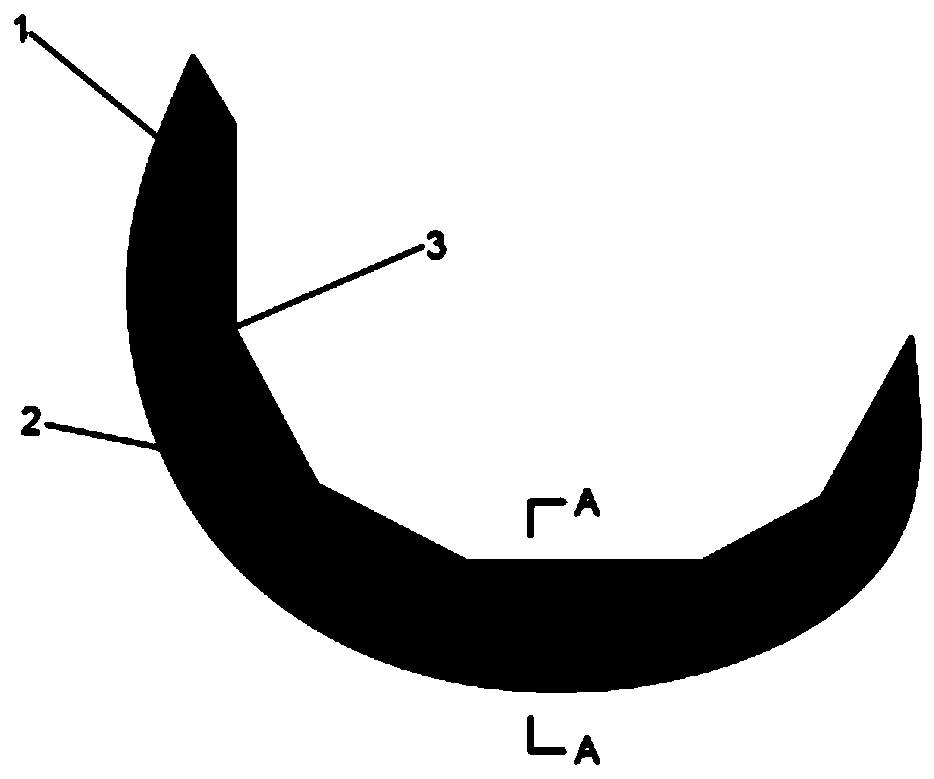

[0018] refer to Picture 1-1 with Figure 1-2 , a polyether ether ketone bionic multi-layer artificial knee joint design and manufacturing method, comprising the following steps:

[0019] 1) After examination, the patient needs artificial knee replacement surgery, and the doctor makes preliminary planning for the surgery;

[0020] 2) Guide the design of the knee joint through the results of preoperative planning: Import the patient's CT impact data into data processing software (such as Mimics21.0), reconstruct the three-dimensional model of the knee joint lesion area model, and resect the lesion part , import the knee joint three-dimensional model data into the three-dimensional model reconstruction software (such as 3-matic13.0), carry out the leveling treatment of the knee joint three-dimensional model, and carry out the finite element analysis on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com