Soldered joint stress concentration testing device and stress concentration testing method based on laser speckle technology

A technology of welding joints and laser speckle, which is applied in the interdisciplinary fields of materials science, optics and mechanics, can solve problems such as poor flexibility, inability to measure actual components, and cumbersome and complicated process of adjusting the optical path, so as to reduce errors and save the cumbersome adjustment of the optical path work, the effect of error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

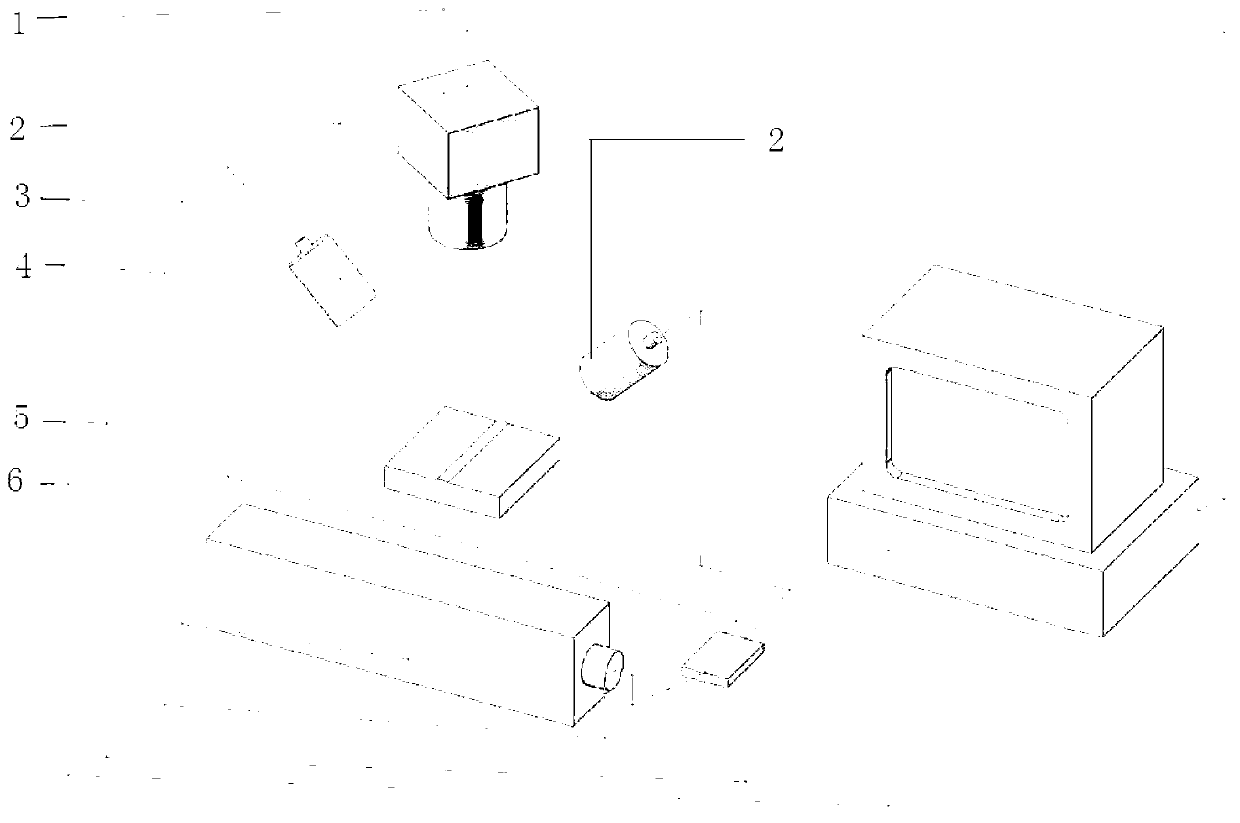

[0035] Specific implementation mode 1. Combination figure 1 This embodiment is specifically described. The device for stress concentration testing of welded joints based on laser speckle technology described in this embodiment includes a digital CCD camera 1, two collimating beam expanders 2, a single-mode laser 3, a fiber coupler 4, Optical fiber beam splitter 5 and computer 6,

[0036] After the laser light emitted by the single-mode laser 3 is coupled by the fiber coupler 4, it is sent to the fiber beam splitter 5 through the optical fiber. The optical fiber is sent to two collimating beam expanders 2,

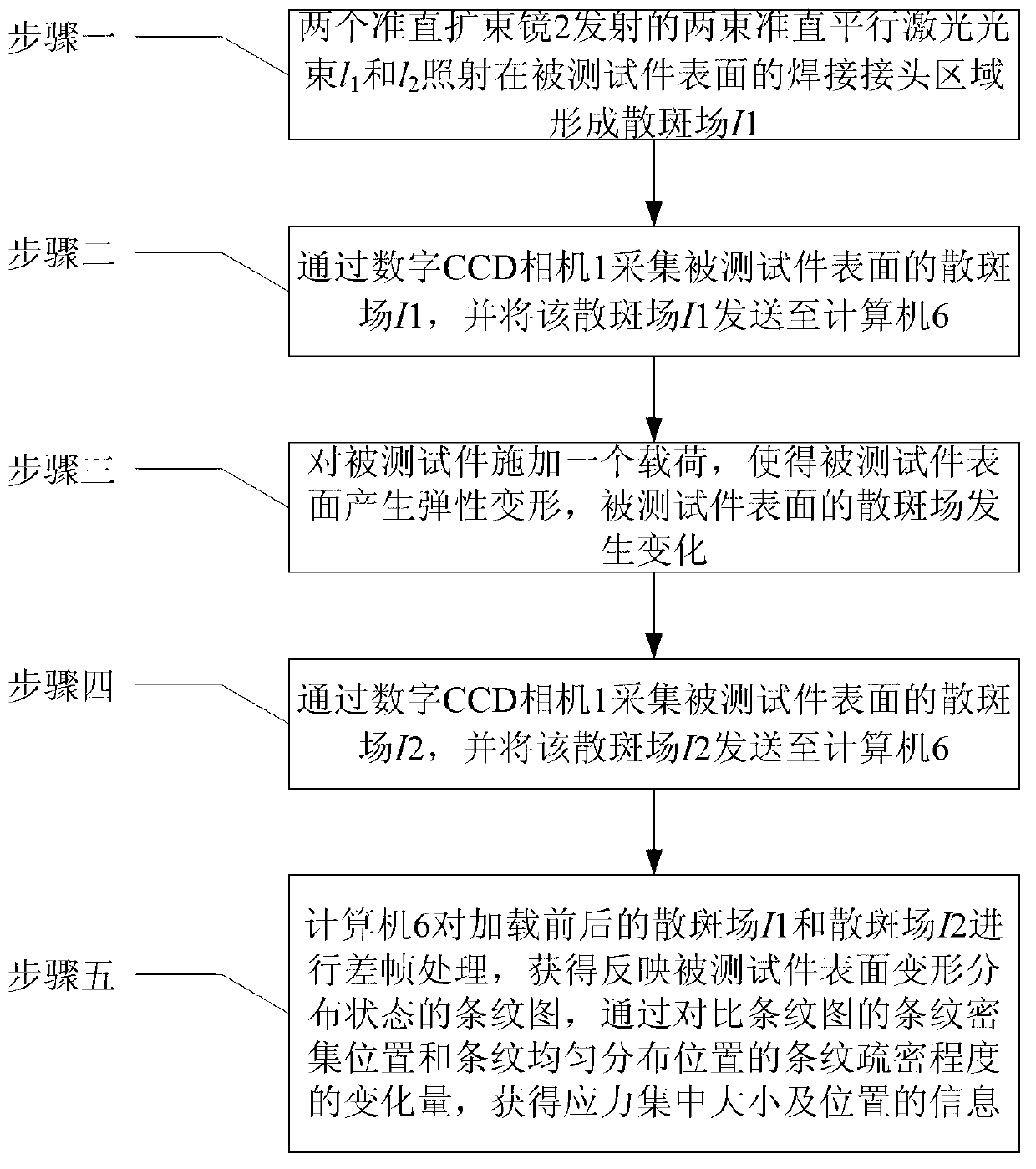

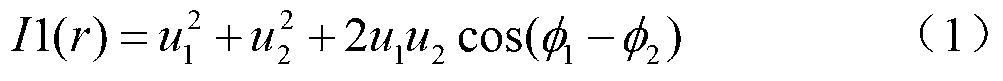

[0037] The two collimated parallel laser beams emitted by the two collimated beam expanders 2 irradiate the welded joint area on the surface of the test piece to form a speckle field, and the two collimated parallel laser beams are located on both sides of the normal of the tested surface And the angle with the normal is the same, and the axes of the two collimated parall...

specific Embodiment approach 2

[0047]Embodiment 2. The difference between this embodiment and the device for stress concentration testing of welded joints based on laser speckle technology described in Embodiment 1 is that the digital CCD camera 1 is an industrial camera with 1.3 million pixels, and the The lens of the camera is a microscopic magnifying lens.

specific Embodiment approach 3

[0048] Embodiment 3. The difference between this embodiment and the device for stress concentration testing of welded joints based on laser speckle technology described in Embodiment 1 is that the single-mode laser 3 is a single-mode He-Ne laser.

[0049] The single-mode He-Ne laser described in this embodiment is a single-mode He-Ne laser with a power of 40 mW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com