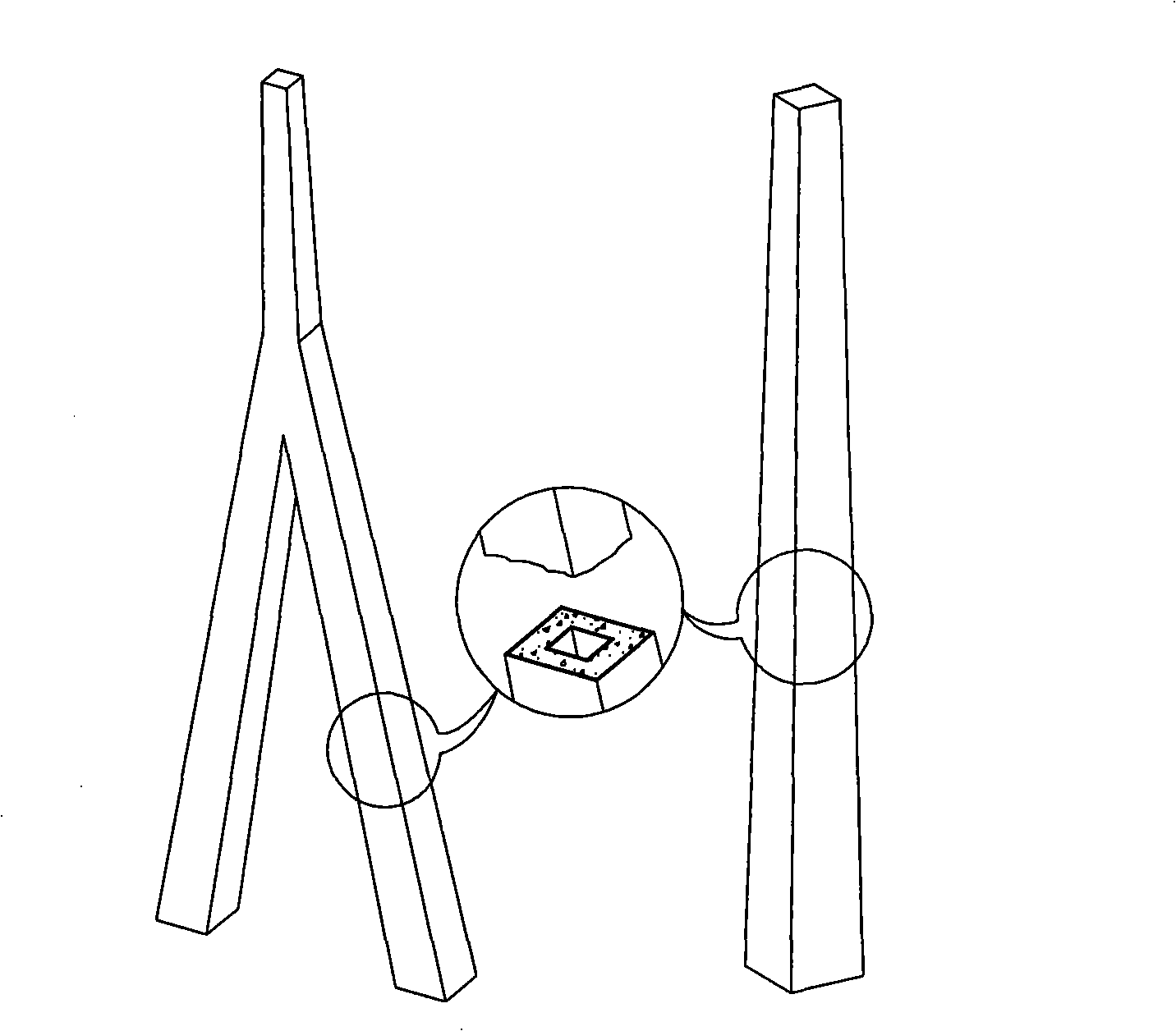

Double-steel tube-concrete combined structural pylon

A combined structure and concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of low damping of steel bridge tower structures, vortex-induced vibration and galloping vibration, and complex stiffening structures, achieving good durability and preventing buckling. , the effect of easy precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

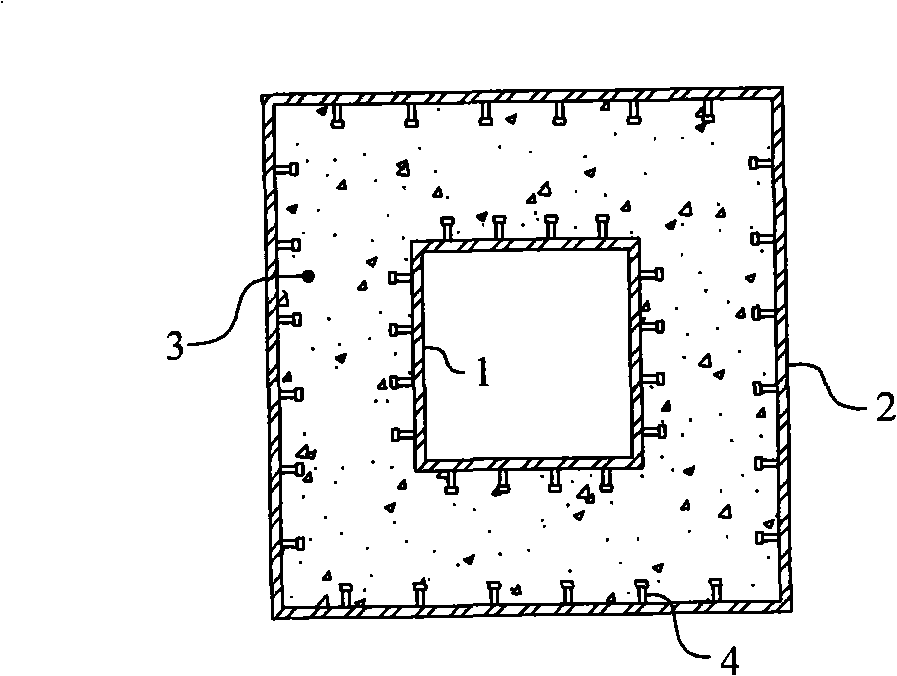

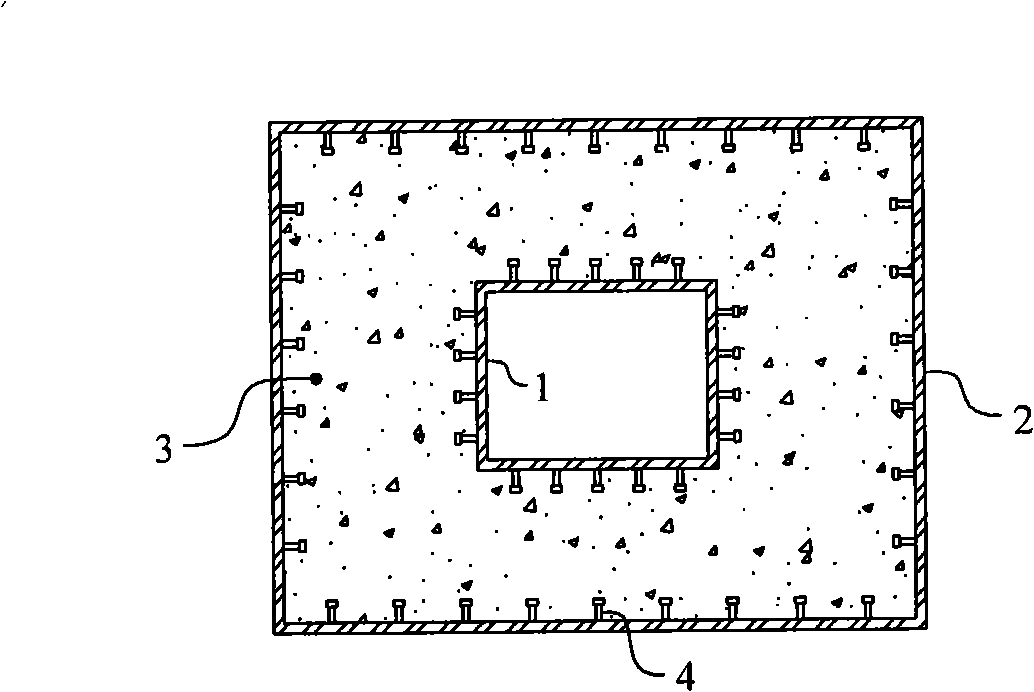

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] In the double steel pipe-concrete composite bridge tower provided by the present invention, each column of the bridge tower is composed of an inner steel pipe 1, an outer steel pipe 2 and concrete 3 poured between them. In order to ensure the mutual restraint between the steel pipe and the concrete, the outer side of the inner steel pipe 1 and the inner side of the outer steel pipe 2 are provided with a connector 4 with shear and pull resistance, and bolts can be used for the connection. According to engineering needs, a certain number of stressed steel bars and structural steel bars can be arranged in the concrete 3 . The cross-section of the bridge tower can be square, rectangular or other polygonal.

[0015] In the bridge tower with double steel pipe-concrete composite structure according to the present invention, the stability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com