Embedded stirring friction spot welding method

A friction stir and embedded technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of affecting the service life of stirring tools, poor appearance of joints, wear of "needle" parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

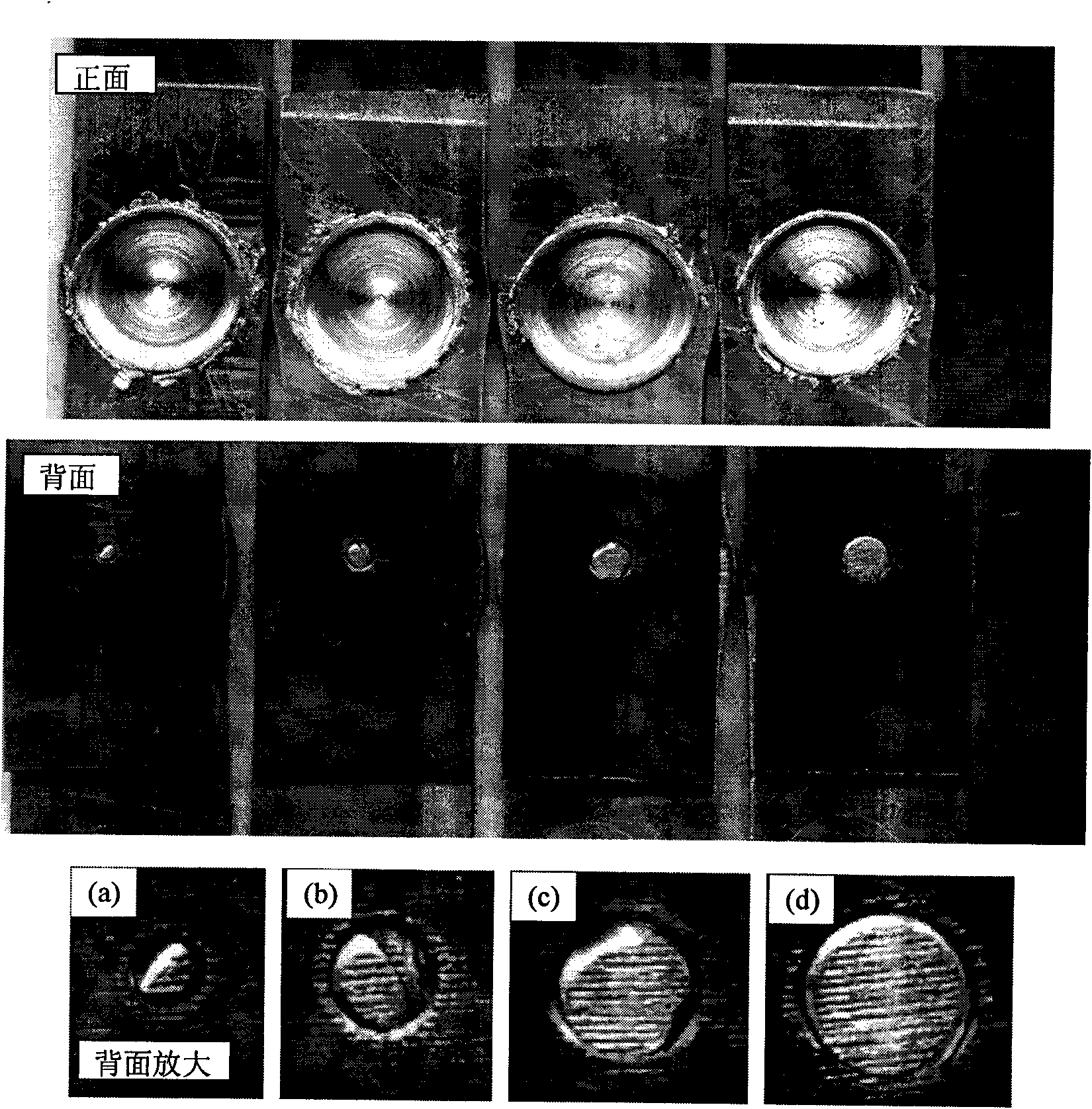

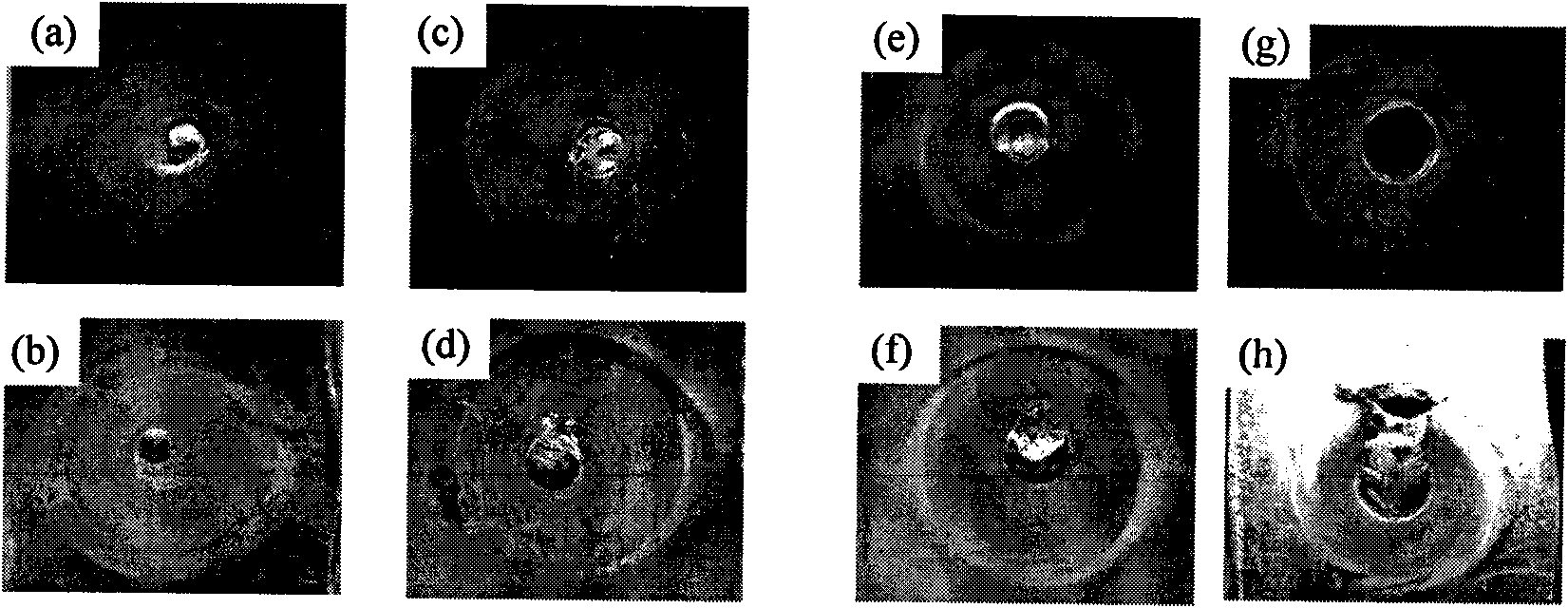

[0043] The invention discloses an embedded friction stir spot welding method, which is especially suitable for the overlapping connection of aluminum (magnesium) and high melting point, relatively hard dissimilar metal materials (such as carbon steel, stainless steel, copper, titanium, etc.). An example (taking the economical aluminum plate and steel plate as an example) is given below to illustrate how to implement embedded friction stir spot welding, and introduce the test results of the welded joint performance to prove the practicability of the present invention.

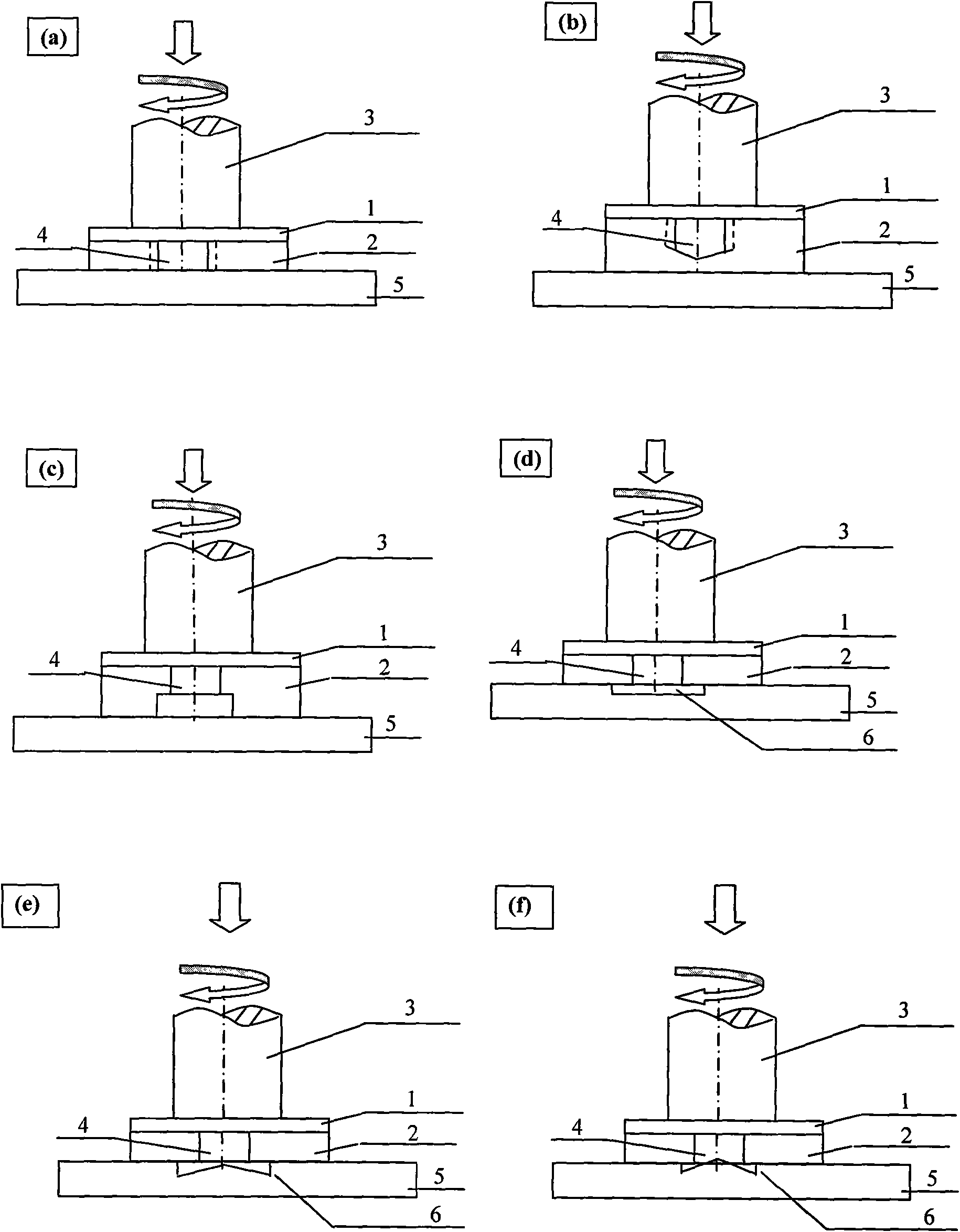

[0044] An embedded friction stir spot welding method, firstly, a hole 4 is provided on the second base material 2; then, the first base material 1 is placed on top of the harder second base material 2, and the second base material 1 is assembled in an overlapping form A base material 1 and a second base material 2; finally, rotate the needle-free stirring head 3 and make the needle-free stirring head 3 contact th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com