Infrared image automatic fault identifying method for high-voltage equipment

An infrared image, fault identification technology, applied in fault location, radiation pyrometry, instruments, etc., can solve the problems of difficult sound, false detection or missed detection, and low efficiency of spark discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

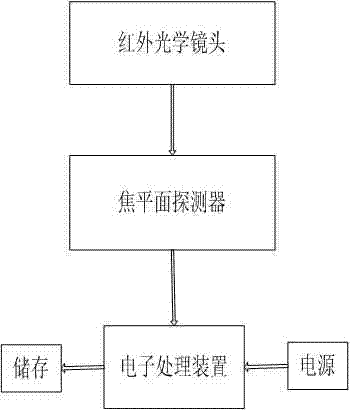

[0041] Figure 1 is a schematic structural diagram of an infrared thermal imager provided in an embodiment of the present invention. The infrared thermal imager used in an embodiment of the present invention to obtain imaging images includes an infrared optical lens, a focal plane detector, and an electronic processing device connected in sequence. The electronic processing device is respectively connected to a power supply and a storage device. The measurement principle of the infrared thermal imager is as follows: infrared thermal imaging technology is a non-contact diagnostic technology for scanning and imaging thermal radiation of objects. The infrared thermal image o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com