Method for preparing photothermal conversion textile

A light-to-heat conversion and fabric technology, which is applied in plant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of limited temperature, difficulty in photothermal nanomaterials, and slow heating rate, achieving mild conditions, great application value, The effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 0.5mL of aniline monomer to 0.5mL of ethanol to obtain a mixed solution, then drop the mixed solution into a beaker containing 45mL of water, 5mL of concentrated hydrochloric acid (HCl mass percentage: ~36%) and 1.141g of ammonium persulfate, and stir for 30s After that, put it in a refrigerator at 6°C, let it stand for 24 hours, and then use a sand core funnel and a 0.45 μm polyvinylidene fluoride filter membrane to filter and wash the sample under reduced pressure to obtain the product polyaniline.

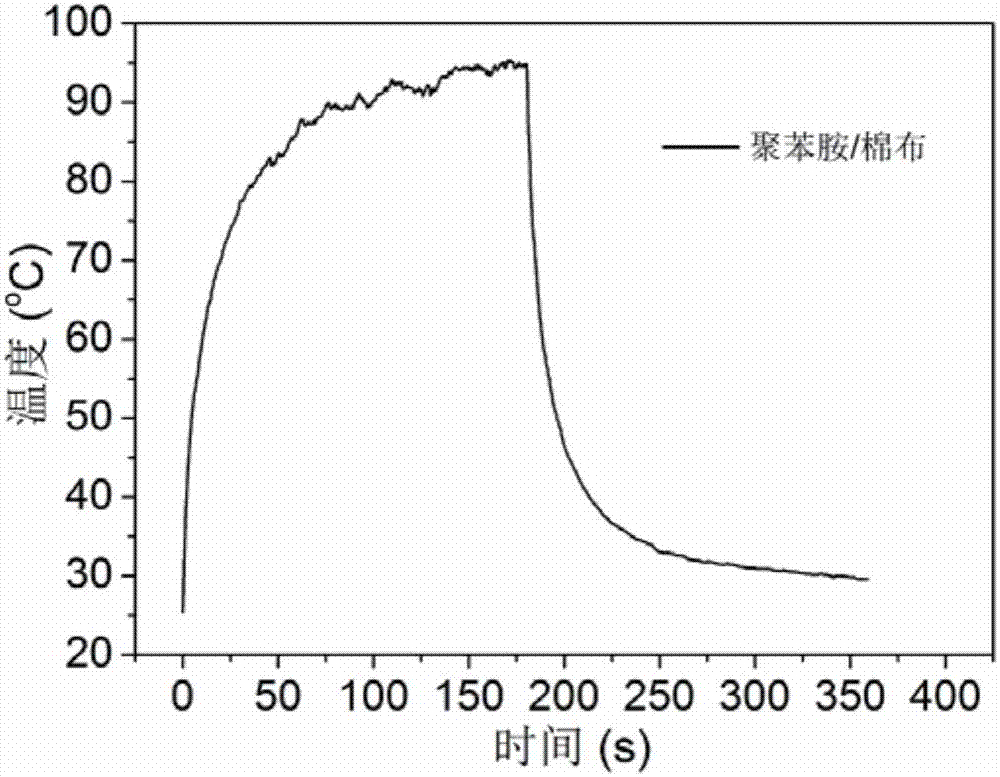

[0027] Re-dissolve the filtered polyaniline in ethanol to prepare an 8 mg / mL ethanol dispersion. 5 mL of the dispersion liquid was evenly dropped onto a 10×10 cm cotton cloth several times, dried in an oven at 60°C for 0.5 h, and the polyaniline / cotton light-to-heat conversion fabric was obtained after drying. At a light intensity of 0.6W / cm 2 Under the irradiation of the xenon lamp simulator, the temperature rise curve of the polyaniline / cotton light-to-heat convers...

Embodiment 2

[0029] Add 40mL of deionized water, 1g of polyvinylpyrrolidone (K-30), 0.08525g of copper chloride dihydrate and 0.6mL of ammonium sulfide aqueous solution into a 50mL polytetrafluoroethylene hydrothermal kettle liner (mass percentage of sulfur element: ~8%), after stirring for 30min, put it into the shell of an iron hydrothermal kettle, react in an oven at 180°C for 12h, and then centrifuge and wash at 10000rpm to obtain the product copper sulfide nanosheets.

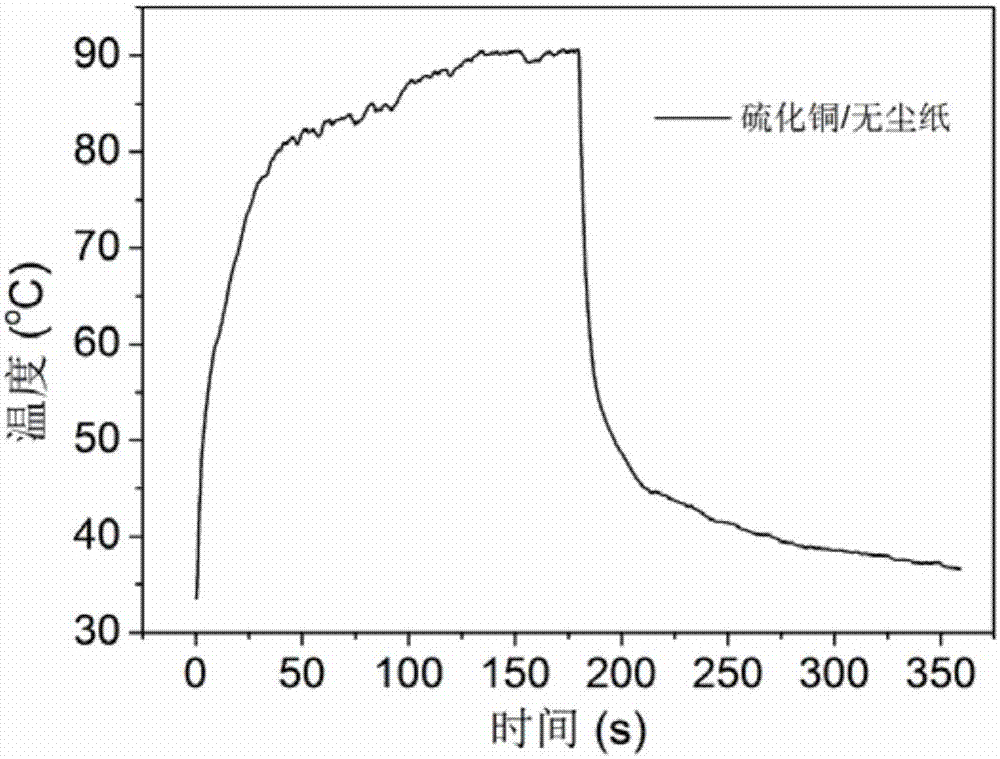

[0030] The copper sulfide nanosheets were redispersed into the aqueous solution to prepare a 2mg / mL aqueous solution. Drop 10mL of copper sulfide water dispersion repeatedly and evenly onto a 5×5cm dust-free paper, and dry it in an oven at 80°C for 1 hour. After drying, the copper sulfide / dust-free paper light-to-heat conversion fabric is obtained. At a light intensity of 0.6W / cm 2 Under the irradiation of the xenon lamp simulator, the temperature rise curve of the copper sulfide / dust-free paper light-to-heat conversi...

Embodiment 3

[0032] Disperse 0.5 g of commercial graphene oxide in 50 mL of deionized water to obtain a 10 mg / mL graphene oxide water dispersion, transfer it to a round bottom flask, heat to 90 ° C in an oil bath, add 1 mL of hydrazine hydrate aqueous solution (hydrazine hydrate Hydrazine mass percentage: 50%), heated to reflux for 1.5h, and centrifuged and washed at 6000rpm to obtain the product graphene.

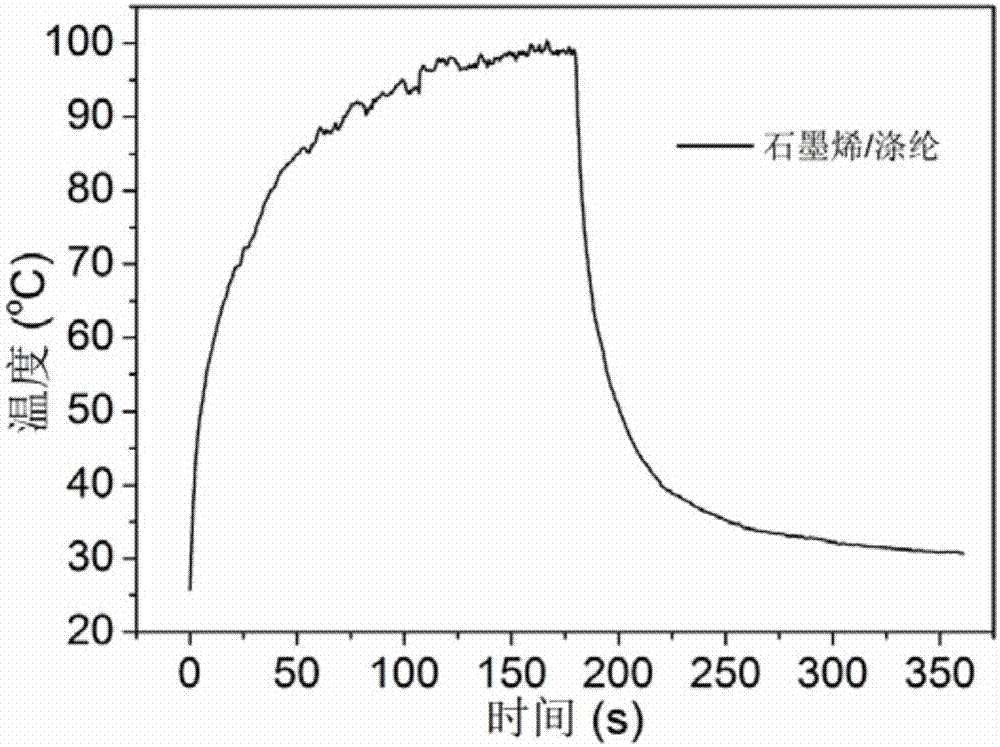

[0033] The obtained product graphene was redispersed into the ethanol solution, and formulated into a 1 mg / mL ethanol dispersion. 20 mL of graphene ethanol dispersion was divided into multiple times and evenly dropped on a 5×5 cm polyester cloth, dried in an oven at 60°C for 0.5 h, and the graphene / polyester light-to-heat conversion fabric was obtained after drying. At a light intensity of 0.6W / cm 2 Under the irradiation of the xenon lamp simulator, the temperature rise curve of the graphene / polyester light-to-heat conversion fabric is given by image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com