Warehousing method and equipment for intensive logistic warehouses

An intensive warehouse technology, applied in the storage method and equipment field of intensive logistics warehouses, can solve the problems of low utilization of warehouse space, sparse storage of goods, low degree of automation, etc., and achieve flexible and diverse operation sequences, efficient storage, Guaranteed to take full advantage of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

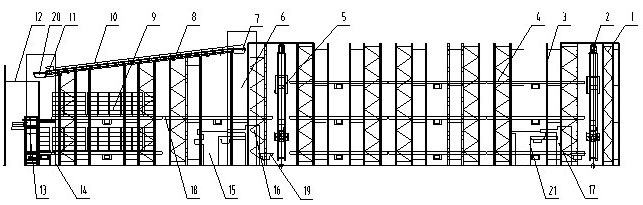

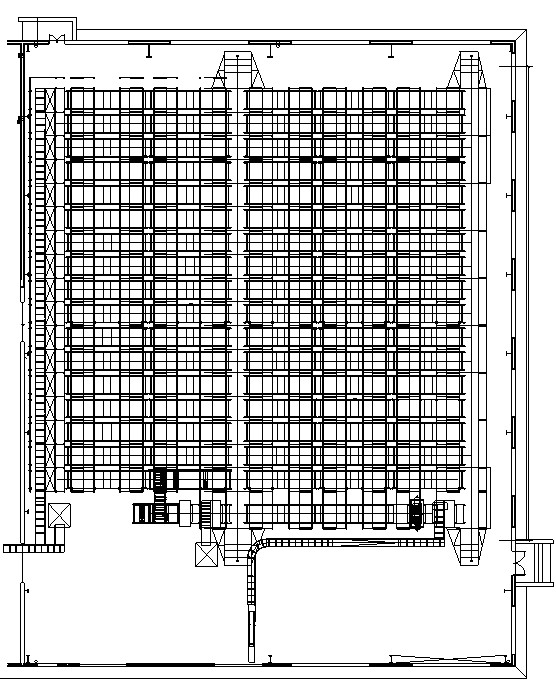

[0030] The present invention will be described below in conjunction with specific embodiments. The invention discloses a warehousing method of an intensive logistics warehousing system. The warehousing method can divide the goods into different types according to the difference in the shipment volume of goods of different brands in the warehouse, and store the goods of different types In different locations of the logistics warehouse, different delivery methods are used for delivery. In this embodiment, according to the size of the shipments in the logistics warehouse, the goods stored in the warehouse are divided into three categories, which are called very small brand goods, small brand goods and mass brand goods in turn. The storage method of this logistics Proceed as follows:

[0031] 1. Classified storage of goods

[0032] Classify and store according to very small brand, small brand, large and medium brand. Due to the small number of brands of very small brand goods, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com