Coal slime floating process

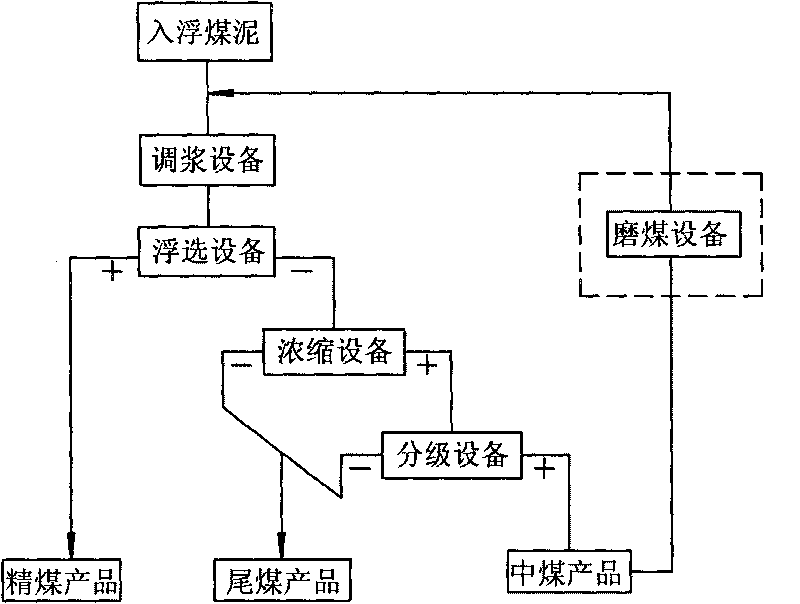

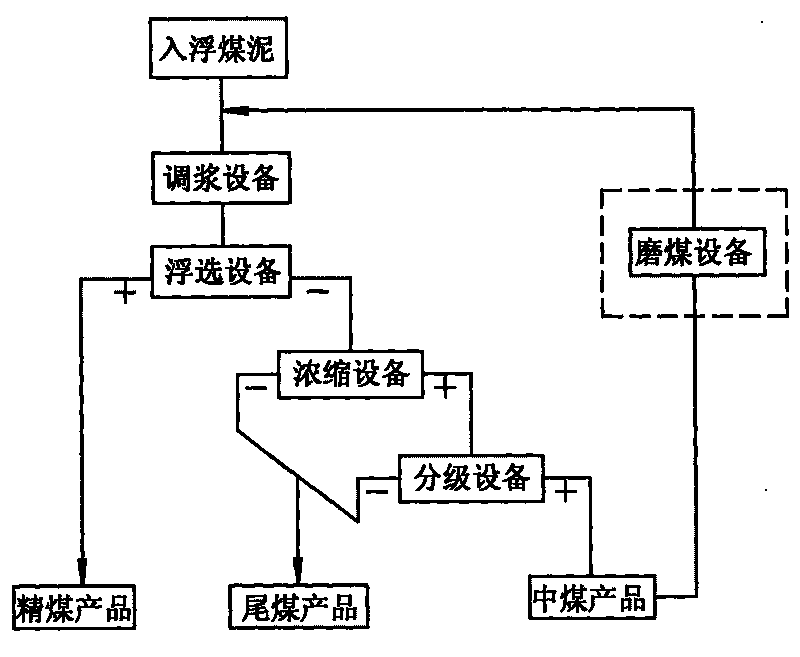

A coal slime flotation and process technology, applied in flotation, solid separation and other directions, can solve the problems of high coal content, low product recovery rate and production efficiency, restricting the quality of clean coal products, etc., and achieves low operating costs and high efficiency. The effect of sorting and improving the quality of clean coal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

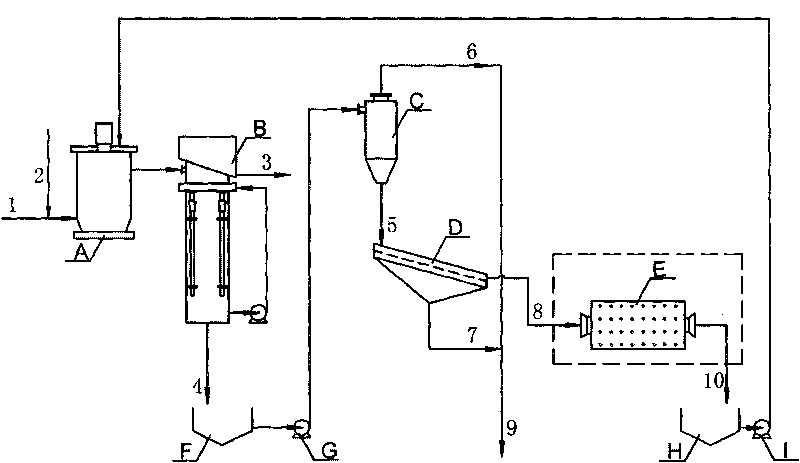

[0014] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0015] Coal slime flotation process of the present invention: its steps are as follows:

[0016] 1. Feed the floating coal slime 1 and the flotation agent 2 into the slurry mixing equipment A for slurry mixing. The slurry mixing equipment A is composed of a mixing tank, a stirring shaft connected with a motor, and blades arranged on the stirring shaft;

[0017] 2. The material stirred by the pulping equipment A flows into the flotation equipment B by itself, and the clean coal product 3 is discharged from the overflow tank on the upper part of the flotation equipment B after being flotation by the flotation equipment B. The sinking primary tailing coal product 4 enters the first tailing coal buffer pool F through the bottom flow port of the flotation device B;

[0018] 3. Use the first mud pump G to pump the first-grade tailings product 4 entering the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com