Method for floating coal by using modified waste oil as flotation agent

A flotation agent and waste oil technology, applied in the field of coal flotation, can solve the problems of soil, water and air pollution, low yield of flotation clean coal, and difficulty in large-scale application, so as to broaden the utilization efficiency and broaden the utilization channels , high cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

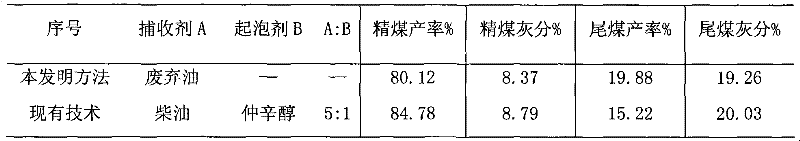

[0026] According to the method described in (1), the waste oil is modified, and the modified waste oil is used as a coal flotation agent, and the coal is floated with the yield and ash content of clean coal and tailing coal as indicators, and In the prior art, the flotation effect of the coal flotation method using diesel oil as collector and sec-octanol as frother was compared.

[0027] The medium and low ash coal Jincheng anthracite raw coal and lump coal are coarsely crushed and finely crushed to obtain flotation coal (particle size ≤ 3mm, ash content 10.5%), using XDF series single-cell flotation machine (volume 200mL, speed 1800r / min), the coal concentration is 80g / L, and the amount of flotation agent per ton of coal is 0.72kg. The flotation results of coal are as follows:

[0028]

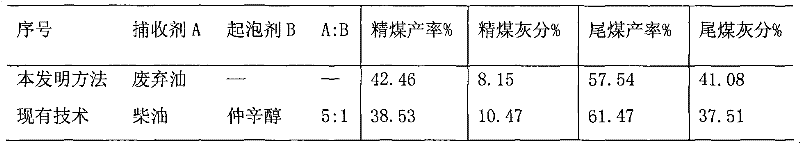

[0029] The medium-ash coal Taoshan Mine lignite raw coal of Heilongjiang Qitaihe Coal Industry Group Co., Ltd. was used to obtain flotation coal (particle size ≤ 3mm, ash content 27.04%) ...

Embodiment 2

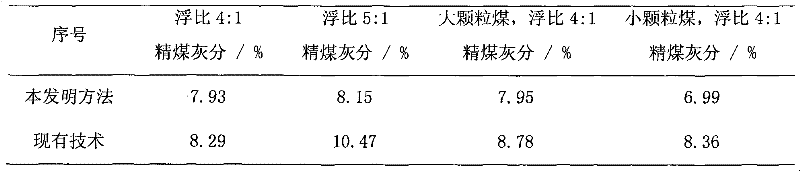

[0032] According to the method described in (1), the waste oil is modified, and the modified waste oil is used as a coal flotation agent, and the clean coal ash is used as an index, and the same coal with different flotation ratios and different particle sizes is used for flotation tests. And compared with the prior art using diesel oil as collector and sec-octanol as frother for flotation of clean coal ash.

[0033] The raw lignite coal from the Taoshan Mine of Heilongjiang Qitaihe Coal Industry Group Co., Ltd. was coarsely crushed and finely crushed to obtain flotation coal (ash content 27.04%), and the XDF series single-slot flotation machine (volume 200mL , the speed is 1800r / min), the coal concentration is 80g / L, and the amount of flotation agent per ton of coal is 0.91kg. 3mm coal, large particle coal refers to coal with a particle size > 3mm) for flotation, and the coal flotation results are as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com